What is a creep test?

A creep test involves subjecting a material to continuous tensile or compressive loading at a constant temperature to observe its deformation over time. This method is particularly vital for materials intended to function under specific operational temperatures while bearing loads. For instance, metals and alloys exhibit significant alterations in their material properties at different temperatures. By conducting a creep test, engineers gain valuable insights into a material’s expected deformation behavior, thus enabling them to design systems capable of withstanding diverse environmental conditions effectively.

In this article, we delve into the intricacies of creep testing, its significance, methodologies, and the critical insights it provides for engineers and designers.

What is the phenomenon of creep?

Creep, within the context of materials science, refers to the phenomenon of gradual plastic deformation that occurs in a material when subjected to sustained stress and elevated temperatures over time. This deformation, albeit gradual, can lead to significant structural changes and potential failure in materials such as metals, ceramics, and plastics.

How to perform a creep test?

The process of conducting a creep test entails meticulous steps to ensure accurate results.

Firstly, the material under examination is subjected to prolonged constant tension or compression loading at a constant elevated temperature. Throughout the test duration, the material’s deformation is meticulously recorded at predefined time intervals. These recorded data points are then plotted on a creep versus time diagram, facilitating a comprehensive visualization of the material’s behavior under stress. It’s worth noting that maintaining a constant temperature throughout the test duration is paramount to mitigate potential thermal expansion or shrinkage effects on the material.

Short-term tests typically last up to approximately 10,000 hours, while long-term tests extend beyond this threshold. To execute these tests meticulously, specialized equipment such as creep testing machines is employed.

Three stages of creep testing

Creep testing unfolds in three distinct stages, each offering valuable insights into the material’s behavior.

- The primary stage, known as primary creep, is characterized by a rapid increase in the creep rate, followed by a gradual slowdown.

- Subsequently, the secondary stage ensues, where the creep rate stabilizes, exhibiting uniform behavior.

- Finally, the tertiary stage marks the onset of accelerated creep rate, leading to specimen failure. In the event of failure, the time for rupture is meticulously recorded. However, if the specimen withstands the test duration without fracturing, creep recovery may be assessed.

Popular standards in creep testing

Several standards govern the execution of creep testing to ensure uniformity and reliability across different testing scenarios. Examples of such standards include:

- ASTM E139

- ASTM D2290

- ASTM D2291

- ASTM D2294

Each standard delineates specific testing procedures and protocols. Adhering to these standards is imperative for engineers and researchers to uphold the integrity and comparability of their test results, thereby fostering advancements in materials science and engineering.

Stress-Relaxation: A complementary analysis

In addition to creep testing, stress-relaxation analysis serves as a complementary methodology to evaluate a material’s behavior under prolonged stress exposure. This method involves deforming a specimen by a predetermined amount and recording the subsequent decrease in stress over time at a constant elevated temperature. The stress-relaxation rate, determined by the slope of the stress-relaxation curve, provides valuable insights into the material’s viscoelastic properties, facilitating a comprehensive understanding of its mechanical behavior.

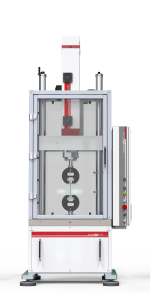

Creep testing machines

EA SERIES

Electromechanical systems

EA (MULTI-ACTUATOR)

Up to 5 load axes

FAQ

What is creep testing?

Creep testing is a vital material testing method aimed at assessing the long-term strength and heat resistance of materials through prolonged exposure to elevated temperatures and constant tensile stress.

How are creep tests performed?

Creep tests involve subjecting specimens to elevated temperatures and constant tensile stress for varying durations using specialized creep testing machines equipped with precise control and measurement capabilities.

What factors influence creep behavior?

Creep behavior is influenced by factors such as the magnitude of the applied load, the temperature environment, and the duration of the applied stress, all of which contribute to the material’s deformation over time.