ELECTRICAL ACTUATORS AND CYLINDERS

Discover our STEP Lab series of electric actuators and cylinders, the result of ten years of global market experience and technological challenges in dynamic applications. Our electromechanical actuators are designed to meet the needs of dynamic applications, including cyclical applications with a high number of cycles and a short stroke.

Features

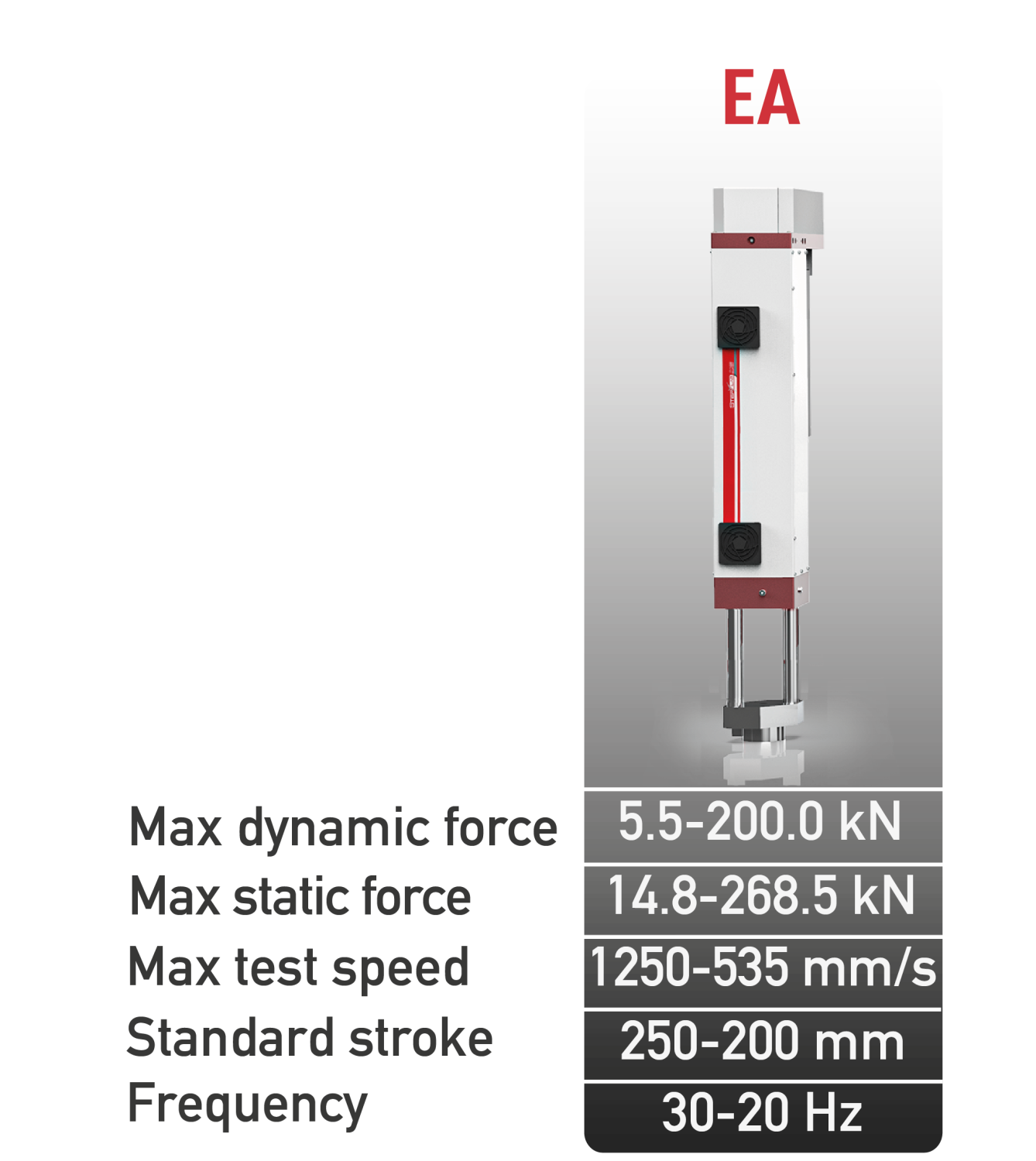

Dynamic load: 5.5-200 kN

Static load: 15-268 kN

Frequency: 20-30 Hz

Type of test

Fatigue

Tensile

Compression

Applications

Materials

Components