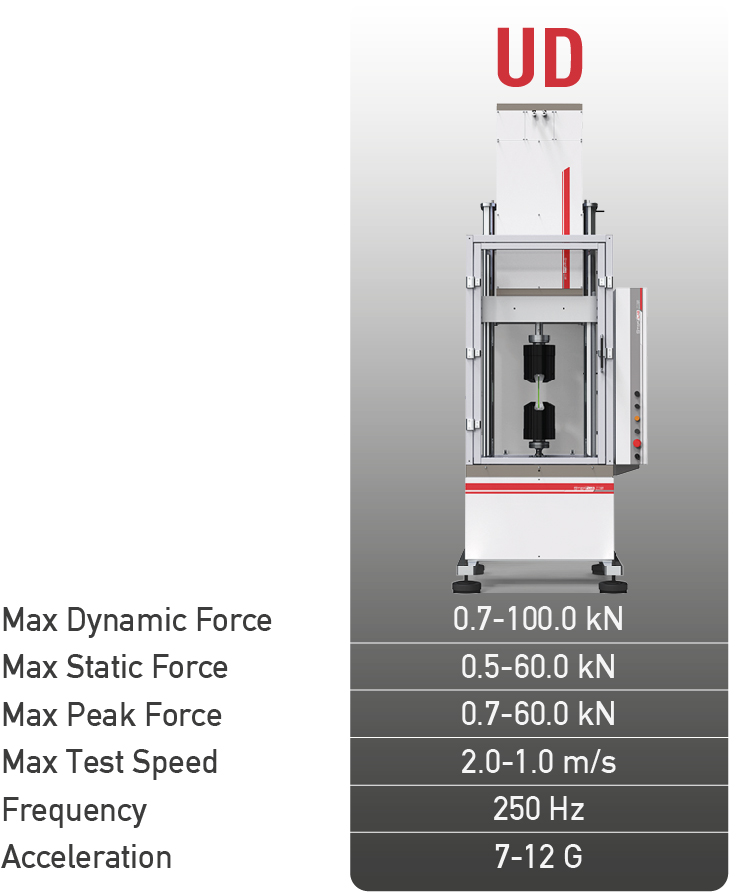

LINEAR ACTUATORS

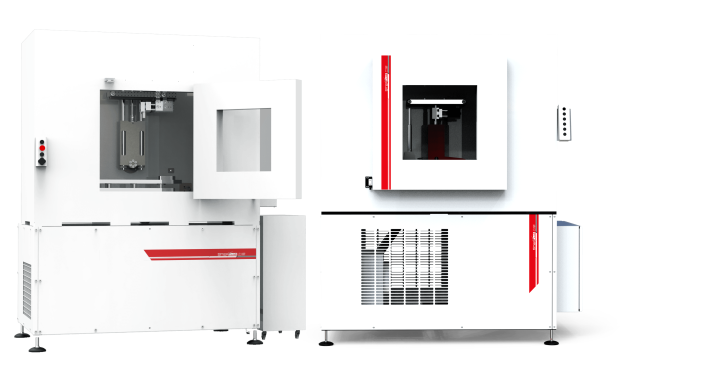

We design and manufacture high-performance linear actuators, ideal for high-dynamic mechanical testing and testing of shock absorbers of cars and motorbikes. With our wide range of electric linear actuators, we are a leader in advanced testing solutions.

Features

Load: 1-100 kN

Type of test

Fatigue

Tensile

Compression

Applications

Materials

Components