EXTENSOMETERS

At STEP Lab, official distributors of Epsilon products, we take pride in offering our customers a wide range of high-quality extensometers. Backed by our experience in the field of testing, Epsilon extensometers stand as an essential solution for strain and tensile measurements across a wide spectrum of applications. But before we delve into the specifics, let’s first understand what extensometers are, explore the two main types, and highlight the numerous advantages they offer.

WHAT IS AN EXTENSOMETER?

An extensometer is a highly precise mechanical or electronic instrument employed for the measurement and quantification of dimensional alterations in materials subjected to mechanical stresses, encompassing tensile, compressive, or flexural forces. This instrumental apparatus typically integrates specialized sensors or strain gauges, meticulously calibrated to detect and record even the minutest variations in a material’s length or deformation. Extensometers are indispensable tools in materials testing, structural analysis, and mechanical properties assessment, furnishing engineers and researchers with invaluable insights into parameters such as:

- elasticity;

- yield strength;

- strain;

- stress-strain behavior (within the context of diverse testing and evaluation applications).

OPTICAL EXTENSOMETER

Optical extensometers, also known as Non-Contact extensometers, are a specialized subset of Epsilon extensometers, leverage advanced optical principles for precise deformation measurements in materials. These instruments are particularly valuable in situations where conventional resistance strain gauges face challenges, such as environmental constraints or irregular specimen shapes.

Operating on the basis of light and optical sensors, optical extensometers typically incorporate a light source (e.g., laser) and a light detector (e.g., photodetector or camera). As the material undergoes deformation, changes in surface attributes—reflectivity, transparency, or the light path—are triggered. The optical extensometer quantifies these alterations, providing accurate deformation measurements. This optical approach proves advantageous in environments with high temperatures, harsh conditions, or unconventional specimen shapes, where traditional electrical strain gauges may be impractical.

Description

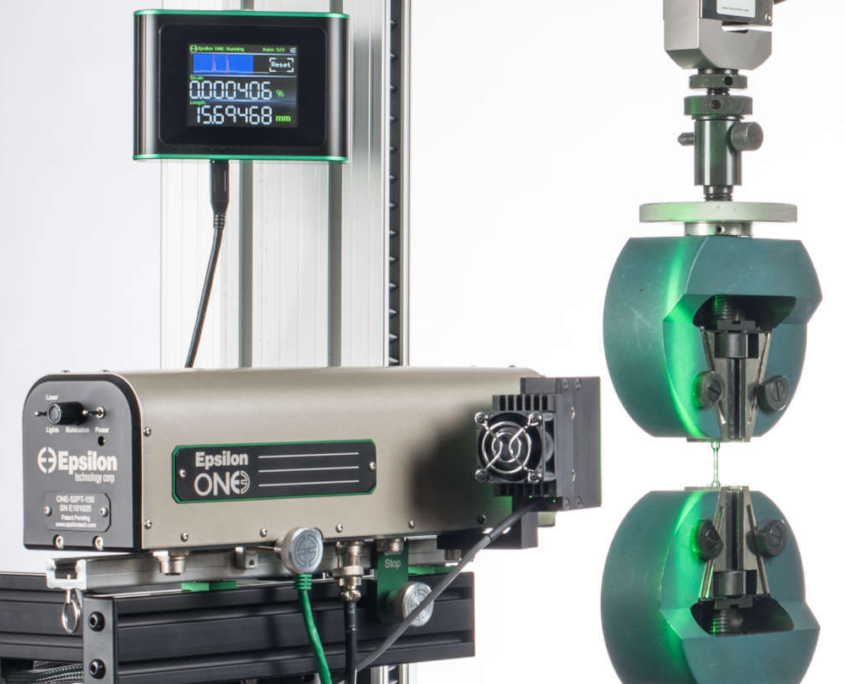

Epsilon ONE® stands out as a precision optical non-contact extensometer designed for diverse material testing applications. With high accuracy meeting ISO 0.5 / ASTM B-1 standards, it excels in measuring axial strain across a broad range of materials, from high-modulus substances like metals and composites to high-elongation materials and delicate specimens. Its applications include cyclic fatigue testing, strain-controlled experiments, deflectometer usage, and measuring crack opening displacements.

Key features encompass ultra-high camera resolution, real-time data rates up to 3000 Hz, and advanced signal processing techniques, ensuring optimal strain resolution and accuracy with minimal noise. The Laser-Assist Alignment System facilitates quick alignment and distance spot checks by projecting pre-aligned laser lines on the specimen, uncovering any misalignment. Precision telecentric lenses on the PT models eliminate errors from out-of-plane movements during tests, addressing a common challenge in many video extensometers.

Setting up for new specimen types is streamlined, requiring minimal training. The desktop user interface software and optional Touch Interface offer continuous digital readouts and status information. Epsilon ONE prioritizes efficiency with the fastest specimen cycle times, enabling auto-start for repetitive tests without software interaction. Instant Reset and Automatic Mark Detection features eliminate the need for frequent software start/stop interactions common in video extensometers.

Additionally, Epsilon ONE generates a calibrated ±10V strain signal as an input for the testing machine’s controller, making it compatible with various materials testing machines, including those equipped with an environmental chamber and window.

Features

- Always on & real-time

- Faster throughput with Instant Reset

- Reliable, automatic mark detection

- Laser Assist Alignment System

- Precision Telecentric Design

- Fully factory calibrated

- Cleaner workspace:No need for an additional computer and monitor

- Retractable high-stiffness mounting

- Selectable multi-line specimen marking

- Wide range of selectable filter and optical settings

- Admin/User Modes.

- Real-time digital output

- Better Strain Control

- Versatile Output Modes:output ±10V as % Strain, Length (mm), or Elongation (mm).

- (Optional) Touch Interface: Access and control the Epsilon ONE without a computer

- Applicable for testing with many ISO and ASTM standards, including:

- ISO 6892-1, 527-2, 527-4, 527-5

- ASTM E8, E9, D3039, D638, A370, D3552, E646

Specifications

| Parameter | Value |

|---|---|

| Field of View | 52-500 mm. See specific optics packages; contact Epsilon for other options. |

| Working Distance | 150-300 mm typical. See specific optics packages; contact Epsilon for other options. |

| Real-Time Data Rate | 300-3000 Hz, >2000 Hz typical. Includes image frame rate, analysis, analog output, and digital output. |

| Analog Output | ±10VDC typical, short-protected. Selectable units & range. Includes 2.4 m (8 ft) shielded output cable with connector for test equipment. |

| Digital Output | 16-64 bit at >2000 Hz typical, over RS232. Includes 1.8 m (6 ft) shielded null modem cable. |

| Resolution | <0.5 µm quasistatic, <2.5 µm dynamic, <0.1 µm creep; Typical RMS resolution at typical settings. Resolution is a function of the optics and filter settings. See Guide for details. |

| Extensometer Class | ISO 9513 Class 0,5 and ASTM E83 Class B-1 or better typical at ≥10 mm gauge length |

| Absolute Accuracy (PT models) | <±1 µm or 0.5% of value, not exceeding ±30 µm typical |

| Absolute Accuracy (CE models) | <±1 µm or 0.5% of value |

| Thermal Drift | Room Temperature Stability <0.002%ε/°C (20 µε/°C) |

| Minimum Specimen Size | < Ø20 μm (0.001”) |

| Gauge Length | 2 mm minimum, ≥4x specimen width or diameter recommended. For gauge lengths <10 mm contact Epsilon. |

| Maximum Elongation | >1000%, limited by field of view and gauge length |

| Maximum Tracking Speed | >1500 mm/second (90,000 mm/minute) |

| Cyclic Testing | >100 Hz typical cyclic test frequency, waveform independent |

| Strain Control | Suitable for monotonic and cyclic strain control applications |

| Out-of-Plane Sensitivity | Allowable out-of-plane motion for ISO 9513 Class 0,5 @15 mm gauge length and ASTM E83 Class B-1: <1000 µm (0.040”) for ONE-PT-xx <25 µm (0.001”) for ONE-CE-xx |

| Power Supply | 100-240 VAC, 50-60 Hz, 100W, IEC 320 C14 receptacle. Specify plug type when ordering |

| System Environment | 10-40°C (50-100°F), for use and storage; 20-80% relative humidity non-condensing environments |

| Host PC (optional) | Requires Windows 7 or 10 PC, 900×550 minimum display, one serial or USB port |

CONTACT EXTENSOMETER

Contact extensometers are another type of Epsilon extensometers used to measure the deformation or elongation of a material under stress or strain. They work by employing a component called “strain gauge”, which is typically a thin wire or a slender strip made of resistive material. These strain gauges are attached to the material being tested.

When the material experiences stress or strain, it undergoes deformation or elongation. This deformation causes the strain gauge to also change its shape, and as a result, its electrical resistance changes in a proportional manner to the deformation. This change in electrical resistance is what allows contact extensometers to make precise measurements of the material’s deformation.

Contact extensometers are valuable tools in materials testing, quality control, and research, as they provide precise data on how materials behave under different levels of stress and strain, helping engineers and scientists understand their mechanical properties.

Description

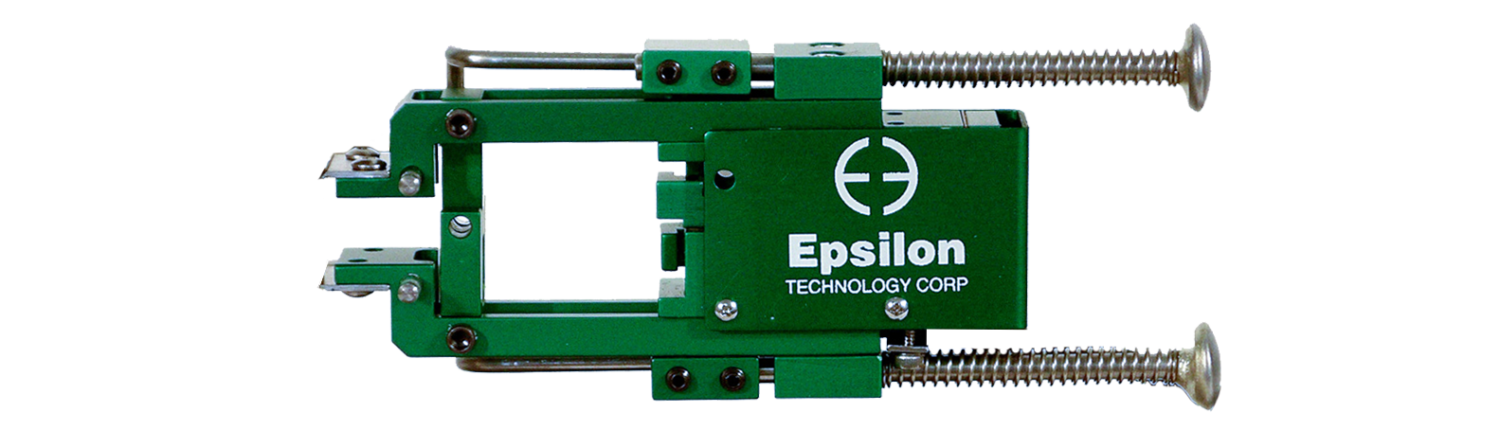

Contact extensometers are designed for versatile material testing, accommodating metals, plastics, composites, and ceramics, providing both tension and compression strain measurements. Their robust dual flexure design ensures durability and insensitivity to vibrations, allowing for high-frequency operation.

Standardized with Epsilon’s quick attach kit, these extensometers facilitate easy, one-handed mounting on the test specimen. The kit is removable, enabling alternative mounting using springs or rubber bands.

Model 3542 extensometers conform to several testing standards, including ISO 6892-1, 527-2, 527-4, 527-5, 10113, as well as ASTM E8, E9, D3039, D638, A370, D3552, E517, and E646.

As strain-gauged devices, they seamlessly integrate with electronics designed for strain-gauged transducers, commonly connecting to a test machine controller with a compatible connector provided by Epsilon. For systems lacking necessary electronics, Epsilon offers various solutions for signal conditioning and connection to data acquisition systems.

For gauge lengths under 20 mm (0.8 inches), consider the more compact Model 3442, while for gauge lengths of 100 mm (4 inches) or more, the Model 3542L is recommended.

Features

- May be left on through specimen failure in most applications.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- All models can measure in both tension and compression and can be used for cyclic testing.

- Standard quick attach kit.

- Rugged, dual flexure design for strength and improved performance.

- All models have mechanical overtravel stops in both directions. Cable stops are used for overtravel protection where required.

- Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer.

- Gauge length adapter kits enable configuration of multiple gauge lengths with one extensometer.

- Replaceable arms and spacers for ease of repair.

- High and low temperature options extend operation from as low as -270 °C to +200 °C (-454 °F to +400 °F).

- Includes the Epsilon Shunt Calibration System for on-site electrical calibration.

- Includes high quality foam lined case.

Specifications

| Parameter | Value |

|---|---|

| Excitation | 5 to 10 VDC recommended, 12 VDC or VAC max. |

| Output | 2 to 4 mV/V, nominal, depending on model |

| Accuracy | Standard configurations meet ASTM E83 class B-1 accuracy requirements for gauge lengths ≥20 mm and class B-2 for <20 mm. All standard configurations meet ISO 9513 class 0,5. A test certificate is included. |

| Linearity | ≤0.15% of full scale measuring range |

| Temperature Range | Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F) |

| Cable | Integral, ultra-flexible cable, 2.5 m (8 ft) standard |

| Standard Quick Attach Kit |

|

| Operating Force | Depends on model configuration; 10 to 100 g typical |

Why choose an extensometer from Epsilon?

Epsilon extensometers offer compelling advantages for various applications:

- High Precision Optical Measurement: Epsilon ONE optical extensometers from Epsilon Tech provide industry-leading resolution, accuracy, and speed in measuring axial strain. This high precision is particularly beneficial for materials like plastics, rubber, and elastomers.

- Innovative Features for Convenience: Epsilon ONE extensometers feature self-setting gauge length and innovative instant reset capabilities. These advancements contribute to the ease of use and efficiency in testing processes, enhancing the overall user experience.

- Versatility and Improved Data Quality: Epsilon extensometers offer increased accuracy and repeatability of test results. This versatility and improved data quality are crucial for material characterization, making Epsilon extensometers a reliable choice across different testing scenarios.