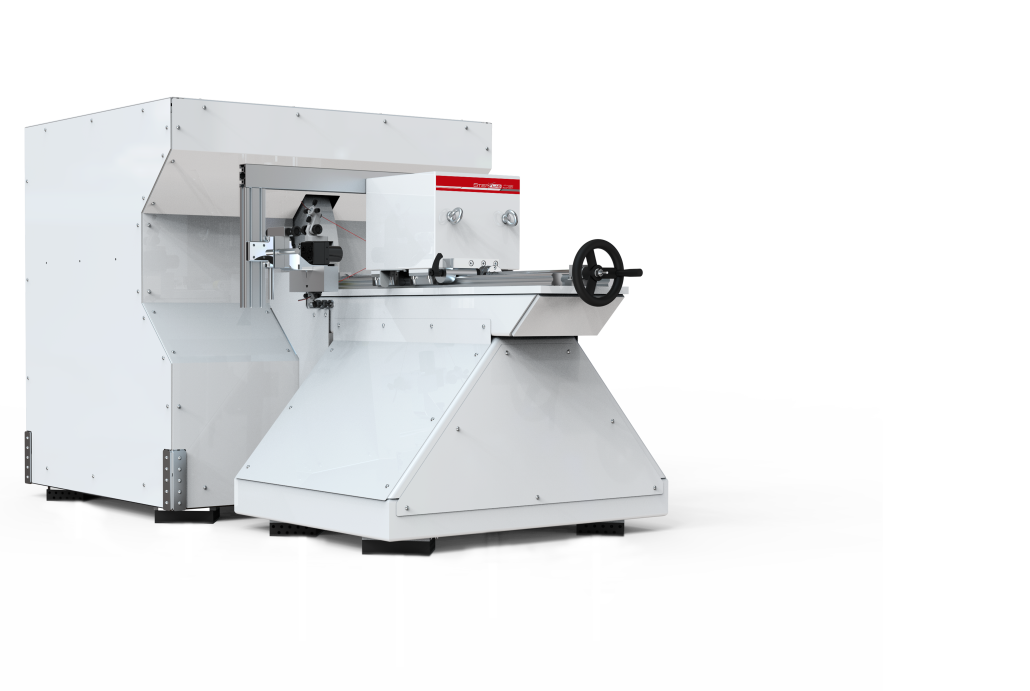

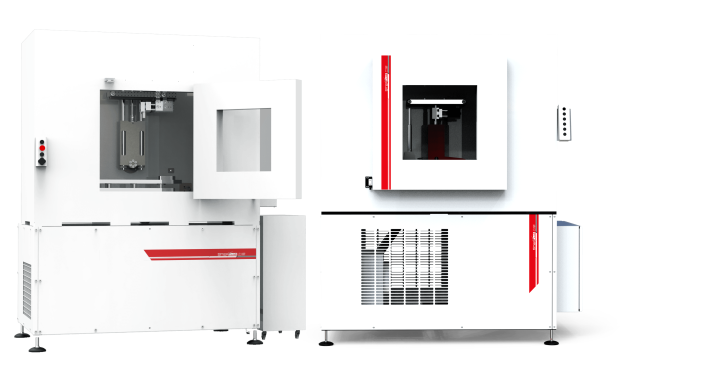

HIGH STRAIN RATE ROTATIONAL SYSTEMS

High-speed dynamic tests are used to replicate car crashes, plane crashes, munitions explosions and other high-impact situations. These tests include both compression and tensile tests, with accelerations up to 40m/s and loads up to 50kN.

Features

Max. Load: 50 kN

Max. Acceleration: 40 m/s

Type of test

High speed

Compression

Tensile

Applications

Plastics

Metal

Composites