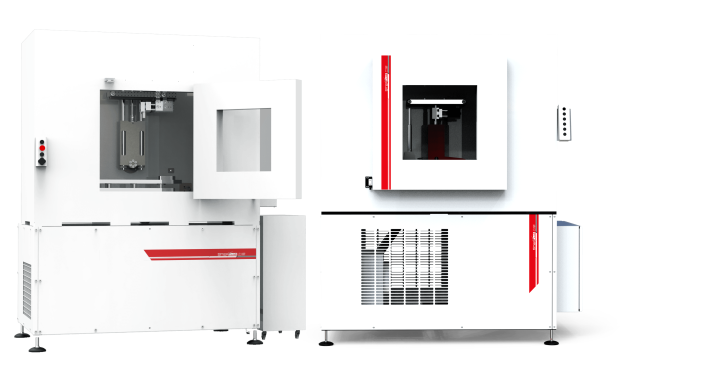

ELECTROMECHANICAL TEST SYSTEMS

FOR DYNAMIC AND FATIGUE TESTS

At STEP Lab, we produce test systems based on high-performance electromechanical actuators. Our technology offers extraordinary flexibility, making these actuators ideal for both static and dynamic testing, with a particular flair for fatigue testing applications.

Features

Max. dynamic force: 200 kN

Max. static force: 268 kN

Max. speed: 1.25 m/s

Type of test

Fatigue

Tensile

Compression

Applications

Materials

Components