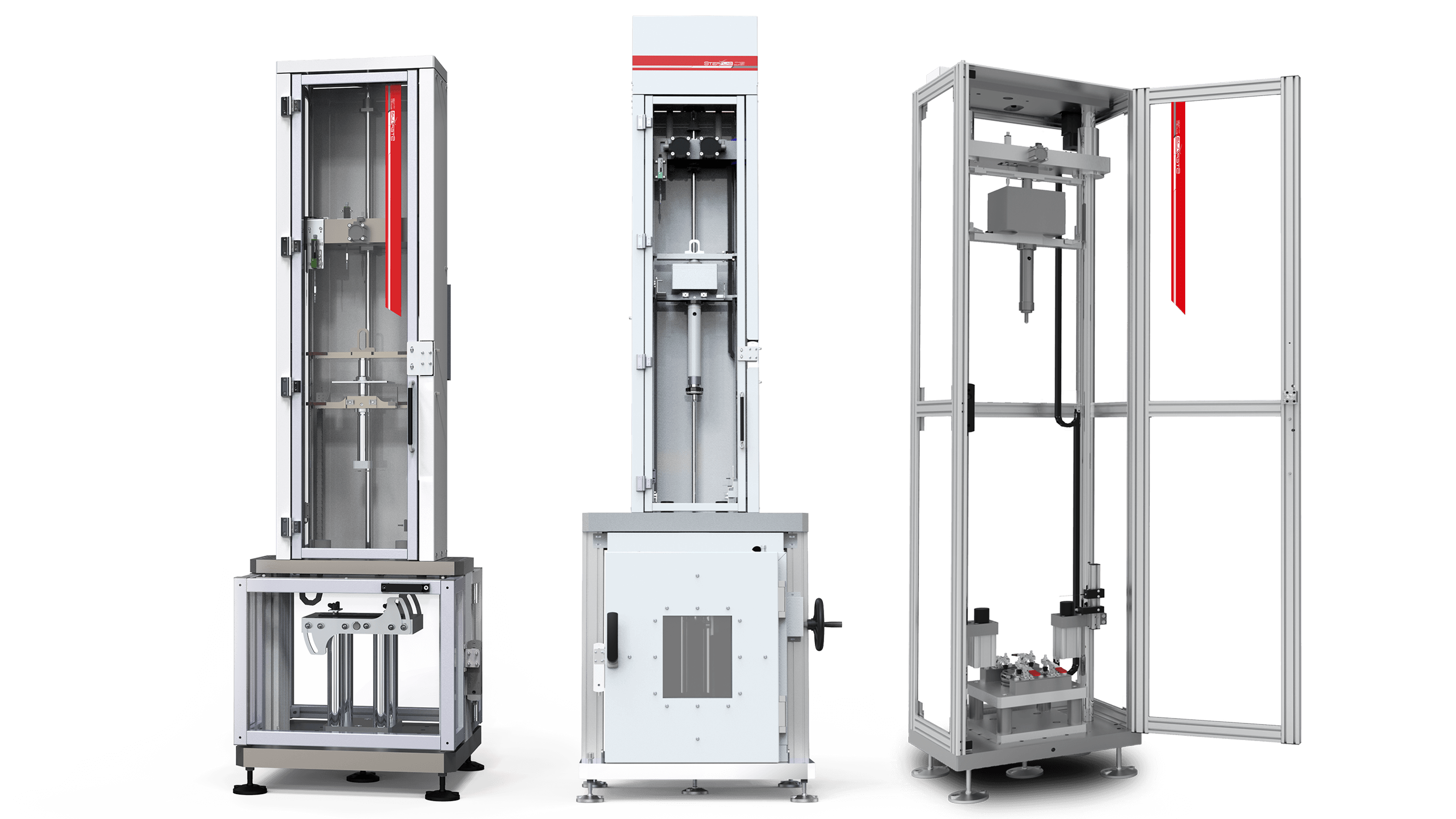

DROP WEIGHT IMPACT TESTING MACHINES

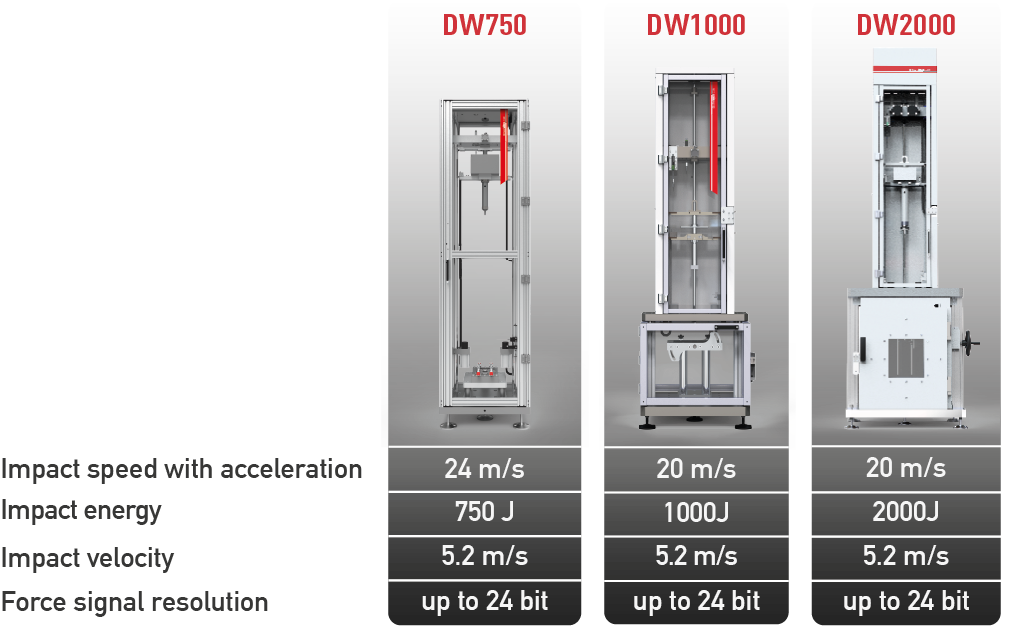

At STEP Lab, we offer a wide range of impact testing machines designed to deliver high performance in impact testing. Our drop weight towers are equipped to perform both single and multiple axial impact tests on standardized products and specimens, ensuring accurate and reliable results.

Features

Max. Energy: 2000 J

Type of test

Impact

Puncture

Applications

Materials

Components