2007

STEP Engineering was born

For over a decade, STEP Lab has been synonymous with excellence in the design and manufacture of static, dynamic and impact testing machines, offering tailor-made solutions for every need. Founded in 2011, we quickly established ourselves as an industry leader, constantly expanding our product range to include linear motor systems for dynamic testing, drop towers for impact testing, high-speed systems and more.

In fact, in addition to the standard products in our catalogue, we at STEP Lab are committed to offering customised solutions, tailored to meet the specific needs of each individual customer. Thanks to our team of highly specialised engineers, we are able to develop and implement unique systems based entirely on electrical actuation and managed by our advanced and unique Test Centre software.

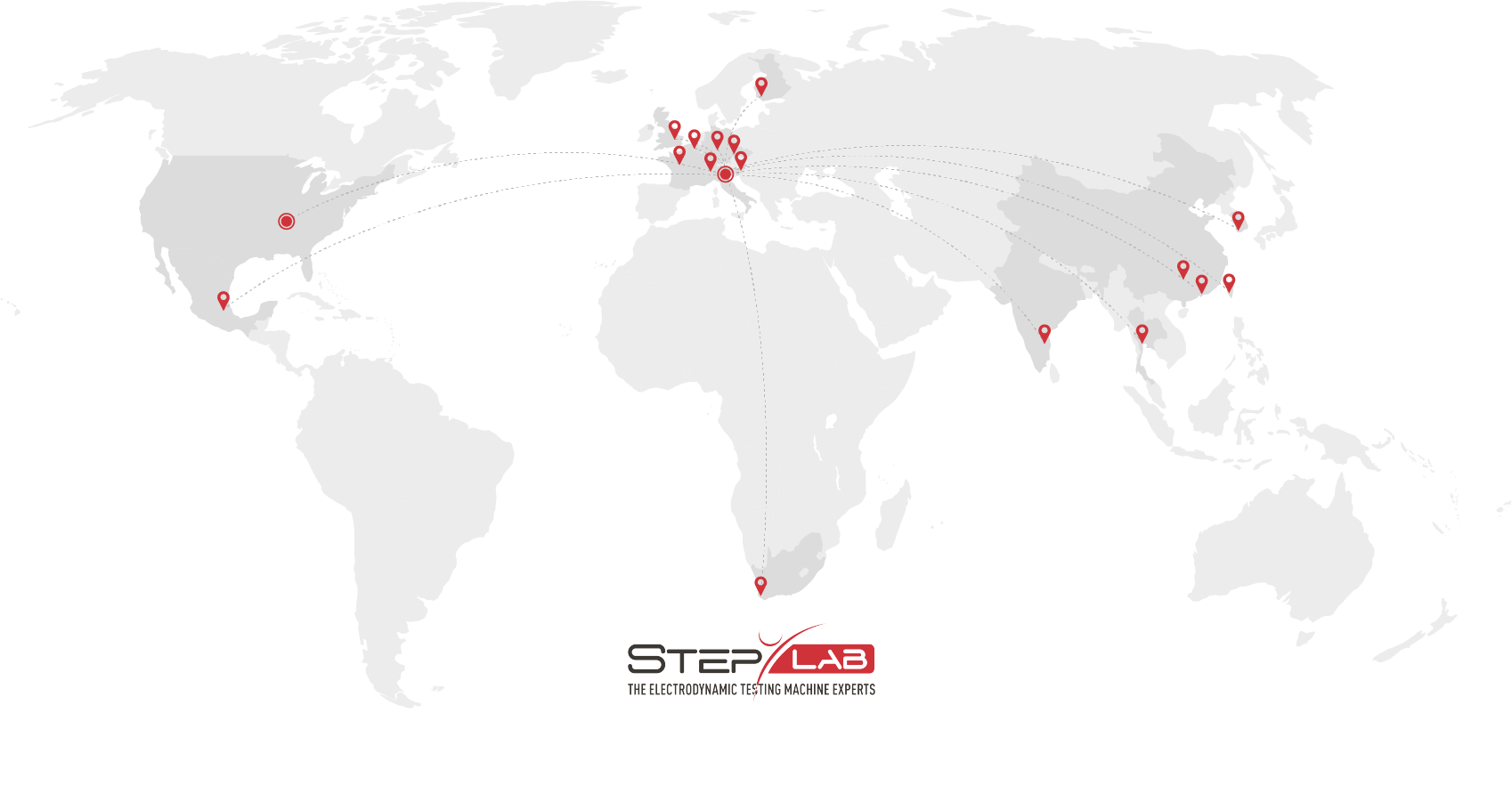

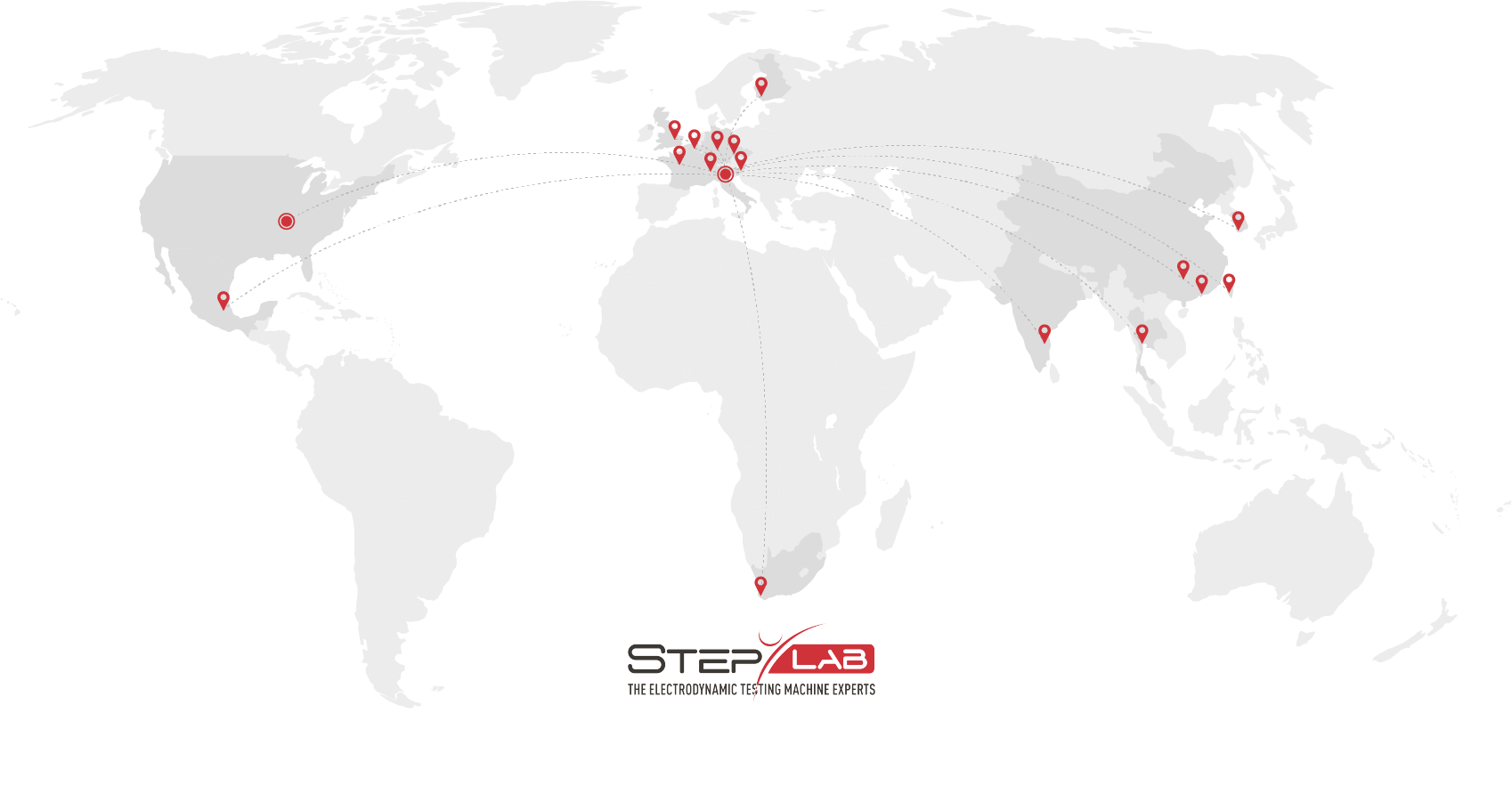

At STEP Lab, we strive every day to propose solutions that redefine standards in the world of testing, and it is thanks to our rapid and steady growth that we have become trusted suppliers to major companies, laboratories and universities worldwide.

Join us on our journey to excellence, where innovation meets precision. STEP Lab is the perfect choice for your mechanical tests!

To be technology leaders in the development of testing systems for materials and products.