ELECTRODYNAMIC ACTUATORS WITH LINEAR MOTORS FOR HIGH STRAIN RATE

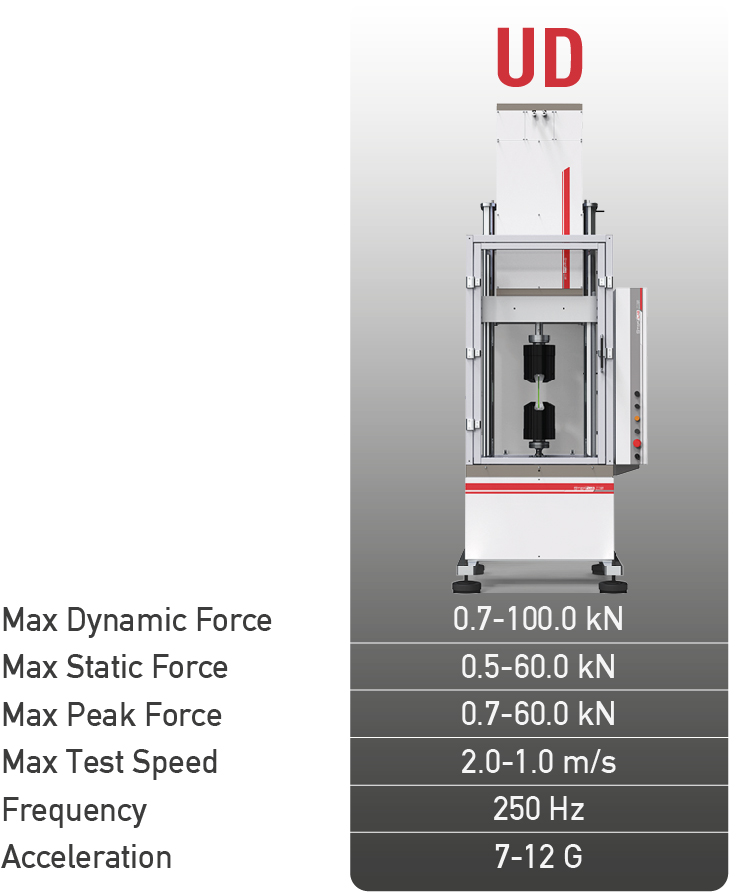

In the development of electrodynamic axes, we have created a new series of machines for very high dynamic applications. This new range of machines, all based on linear motors, is divided into two families: HUD, suitable for endurance tests thanks to its high continuous dynamic forces, and XUD, dedicated to short-duration tests with the achievement of higher accelerations.

Features

Max. Acceleration: 100G

Type of test

High speed

Applications

Materials