BIAXIAL TESTING MACHINE FOR BELLOWS TEST

At STEP Lab, we specialize in designing and manufacturing testing machines for intensive simulation of bellows. Our machines are utilized in the automotive industry to rigorously test shock absorber bellows, steering gear bellows, and CVJ boots.

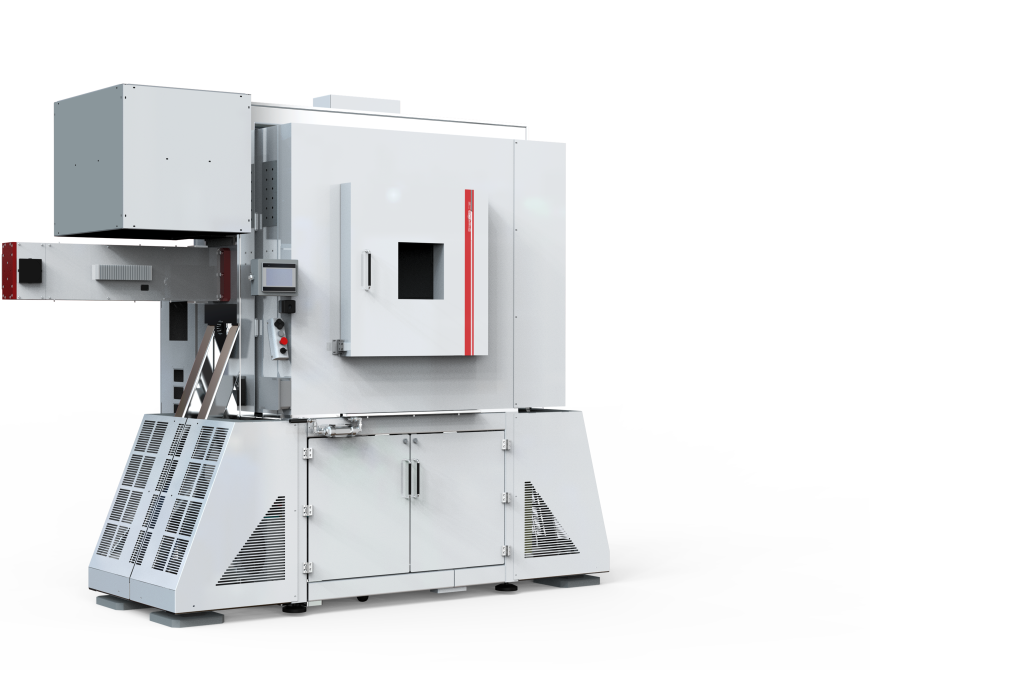

These types of polymer products must endure prolonged stresses and maintain a long lifecycle without compromising their mechanical seal and high mobility. To address this, we have developed a biaxial system featuring two linear actuators (UD02 and UD04) and a two-stage climatic chamber. The chamber’s temperature range spans from -40°C to 150°C, with humidity control from 10% to 90% relative humidity within the temperature range of +10°C to +90°C. Additionally, it includes a water and pollutant nebulizer.

Key features and Performance

- Horizontal Actuator UD04: Dynamic force of 4.0 kN

- Vertical Actuator UD02: Dynamic force of 2.4 kN

- Climatic Chamber: Internal air pressure and vacuum regulation

- Water and mold spray system

Standards compliance

- NISSAN spray test

- SUBARU spray test

- HONDA spray test

- HITACHI spray test

- BOSCH leakage test

- FORD durability test with internal pressure

No maintenance

High performance

High efficiency

Wide range of use

Quick and easy installation

FEATURES

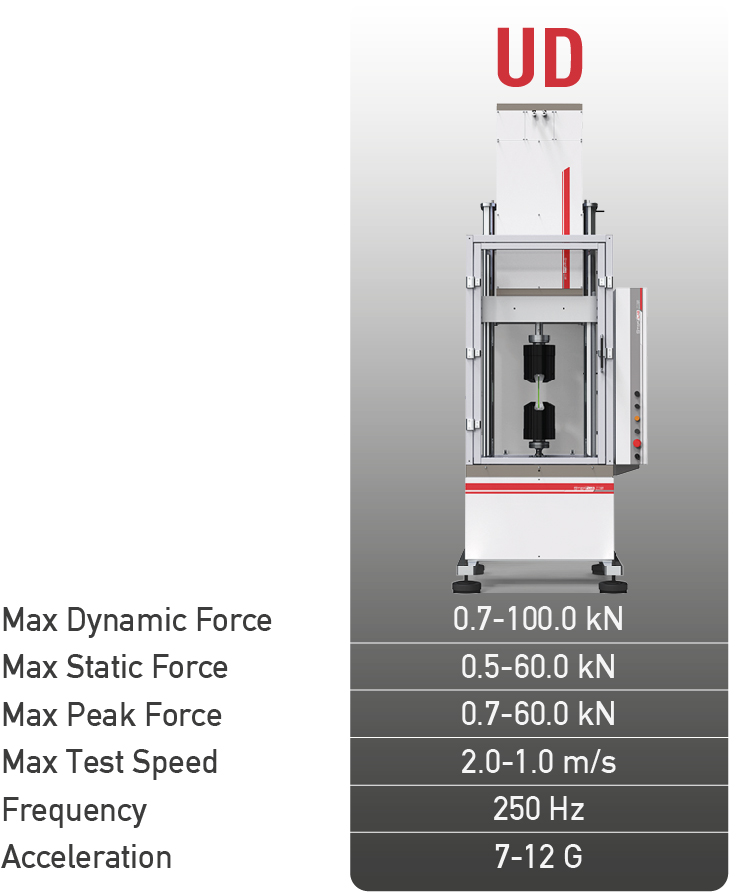

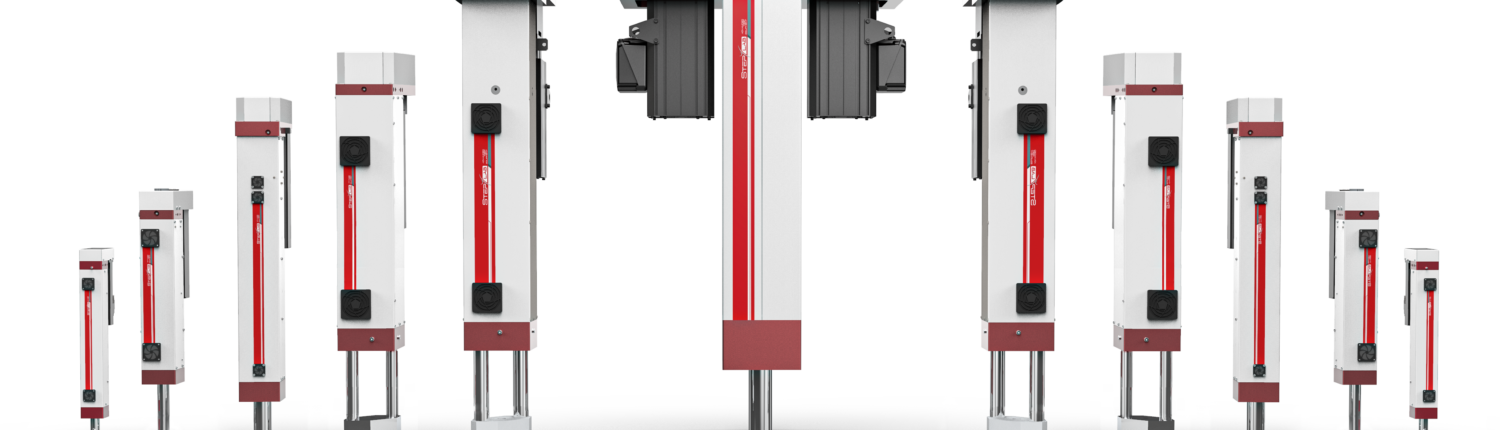

| UD SERIES | UD01 | UD02 | UD04 | UD08 | UD012 | UD025 | UD030 | UD050 | UD075 | UD100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Max. Dynamic Force | 0.70 kN | 2.40 kN | 4.00 kN | 8.00 kN | 12.00 kN | 25.00 kN | 30.00 kN | 50.00 kN | 75.00 kN | 100.00 kN |

| Max. Static Force | 0.54 kN | 1.76 kN | 2.90 kN | 5.80 kN | 8.70 kN | 14.50 kN | 19.20 kN | 29.00 kN | 43.50 kN | 58.00 kN |

| Max. Test Speed | 2.00 m/s | 2.00 m/s | 2.00 m/s | 2.00 m/s | 2.00 m/s | 1.00 m/s | 2.00 m/s | 1.00 m/s | 1.00 m/s | 1.00 m/s |

| Max. Test Frequency | 250* Hz | 250* Hz | 250* Hz | 250* Hz | 250* Hz | 100* Hz | 250* Hz | 100* Hz | 100* Hz | 100* Hz |

| Standard Stroke | 80 mm | 100 mm | 80 mm | 80 mm | 80 mm | 85 mm | 80 mm | 85 mm | 85 mm | 85 mm |

| Cooling | Air | Air | Air | Air | Air | Water closed circuit | Water closed circuit | Water closed circuit | Water closed circuit | Water closed circuit |

| Working Temperature | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C |

| Facility Requirement | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V |

* On request

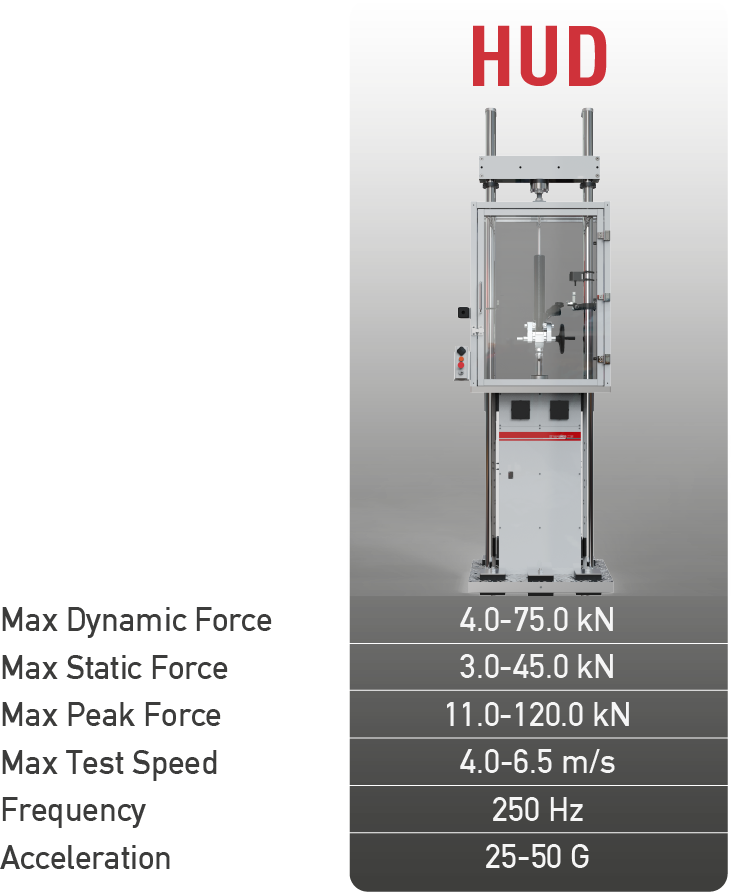

| HUD SERIES | HUD010-HUD010L | HUD014-HUD014L | HUD020-HUD020L | HUD030-HUD030L | HUD040-HUD040L | HUD060-HUD060L | HUD080-HUD080L | HUD120-HUD120L |

|---|---|---|---|---|---|---|---|---|

| Max. Peak Force | 11.00 kN | 12.70 kN | 22.00 kN | 33.00 kN | 40.00 kN | 66.00 kN | 80.00 kN | 120.00 kN |

| Max. Dynamic Force | 4.00 kN | 5.00 kN | 8.00 kN | 12.00 kN | 25.00 kN | 24.00 kN | 50.00 kN | 75.00 kN |

| Max. Static Force | 3.00 kN | 3.50 kN | 6.00 kN | 9.00 kN | 15.00 kN | 18.00 kN | 30.00 kN | 45.00 kN |

| Max. Test Speed | 4.00-6.00 m/s | 3.50 m/s | 4.00-6.50 m/s | 4.00-6.50 m/s | 1.70-3.30 m/s | 4.00-6.50 m/s | 1.70-3.30 m/s | 1.70-3.30 m/s |

| Max. Test Frequency | 125* Hz | 125* Hz | 125* Hz | 125* Hz | 100* Hz | 125* Hz | 100* Hz | 100* Hz |

| Standard Stroke | 200 mm | 170 mm | 200 mm | 200 mm | 269 mm | 200 mm | 269 mm | 269 mm |

| Cooling | Air | Air | Air | Air/Water closed circuit | Water closed circuit | Air/Water closed circuit | Water closed circuit | Water closed circuit |

| Working Temperature | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C |

| Facility Requirement | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V |

* On request

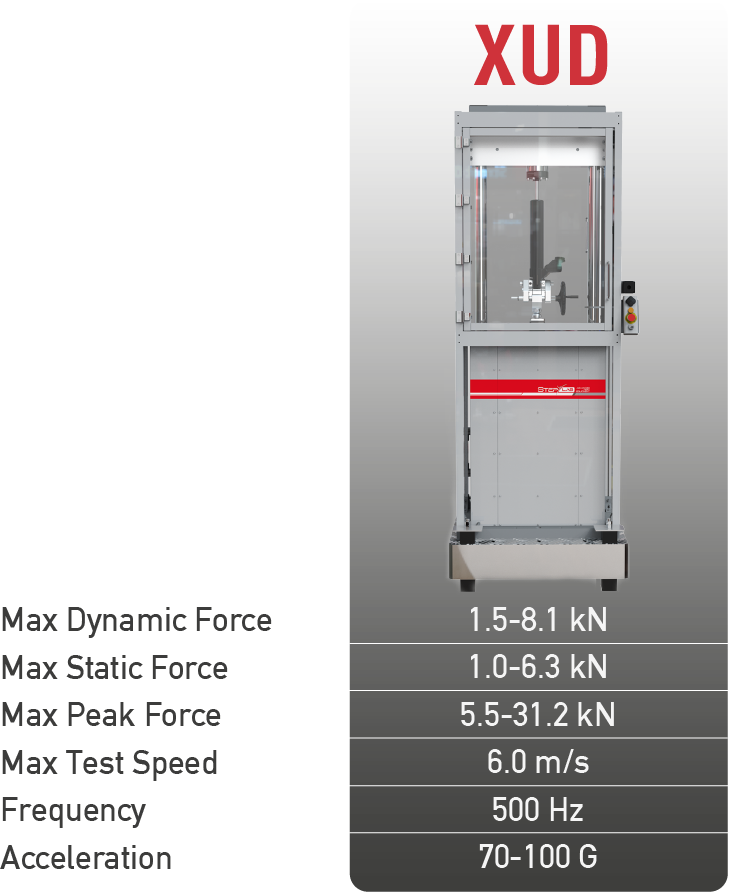

| XUD SERIES | XUD05 | XUD010 | XUD020 | XUD030 |

|---|---|---|---|---|

| Max. Peak Force | 5.50 kN | 10.40 kN | 20.50 kN | 31.20 kN |

| Max. Dynamic Force | 1.50 kN | 2.70 kN | 5.40 kN | 8.10 kN |

| Max. Static Force | 1.00 kN | 2.10 kN | 4.20 kN | 6.30 kN |

| Max. Test Speed | 6.00 m/s | 6.00 m/s | 6.00 m/s | 6.00 m/s |

| Max. Speed at Peak Force | 4.00 m/s | 4.00 m/s | 4.00 m/s | 4.00 m/s |

| Max. Test Frequency | 500* Hz | 500* Hz | 500* Hz | 500* Hz |

| Standard Stroke | 220 mm | 220 mm | 220 mm | 220 mm |

| Cooling | Air | Air | Air | Air |

| Working Temperature | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C |

| Facility Requirement | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V |

* On request

STEP Lab provides customized testing solutions tailored to your product and material testing needs.

This specific biaxial testing machine with a climatic chamber is designed for MPE.

Leakage and durability tests comply with major industry standards, including those from Ford, Bosch, Nissan, Subaru, Honda, and Hitachi.