Testing materials under realistic conditions is essential to ensure durability, safety, and performance. ISO standards provide internationally recognized methods to evaluate materials consistently and accurately.

For flexible foams used in seating and upholstery, one of the most relevant standards is ISO 3385, which defines a method for fatigue testing through constant-load pounding.

WHAT IS ISO 3385?

ISO 3385 defines a standardized method to assess the loss in thickness and hardness of soft, flexible cellular materials—such as those used in upholstery and vehicle seats—after repeated mechanical stress. This method is especially relevant for materials based on rubber latex or polyurethane, ensuring consistent quality and long-term performance in load-bearing applications.

While ISO 3385 helps simulate the wear these materials might experience during use, the results may not directly reflect exact service life but are instead used to compare materials under identical conditions.

ISO 3385 – SCOPE OF THE TEST

The standard applies to both standard-sized samples cut from foam blocks (slabstock) and molded components. The test focuses on evaluating degradation caused by repeated mechanical pounding, simulating real-world usage over time.

Note: ISO 3385 does not specify the detailed engineering requirements for the fatigue testing apparatus.

ISO 3385 – SAMPLE SPECIFICATIONS

According to ISO 3385, the test specimen must be a right parallelepiped with dimensions:

- 380 mm x 380 mm

- Thickness: 50 mm ± 2 mm

By agreement, the test can also be conducted on molded parts with different dimensions. Before testing, the material must be:

- Aged for 72 hours after manufacturing

- Conditioned for at least 16 hours at

- 23 °C / 50% relative humidity or

- 27 °C / 65% relative humidity

ISO 3385 – THREE PHASES OF TESTING

1. Initial Measurement: Thickness and Hardness

The test begins with an initial assessment of the specimen:

- Thickness is measured under a 5 N preload

- Indentation hardness index is measured at 40% indentation with a 30-second hold time, following ISO 2439 Method A

2. Fatigue Test: Constant-Load Pounding

The core of ISO 3385 involves 80,000 cycles of constant-load pounding:

- The indenter operates at a frequency of 70 ± 5 shocks/min

- The specimen must be larger than the indenter but smaller than the support plate

- A maximum force of 770 N must not be exceeded during testing

- The test can be conducted under standard or controlled climate conditions

3. Final Measurement: Thickness and Hardness

After the fatigue test:

- A waiting period of 10 ± 5 minutes is observed

- Thickness and indentation hardness are re-measured using ISO 2439 Method A

- Results are reported as percentage loss in both hardness and thickness

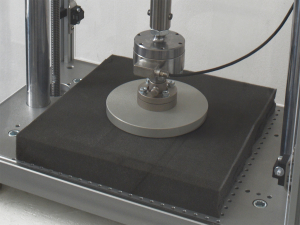

TESTING MACHINE FOR ISO 3385

STEP Lab offers the EA Series, electromechanical testing machines ideal for ISO 3385 fatigue testing and designed for high loading rates.

A wide selection of indenters and support plates ensures compliance with ISO 3385 standard. Whether testing standard specimens or molded parts, STEP Lab provides the tools for reliable, repeatable results.

To find out all the details on EA Series, click the button below.