At STEP Lab, our focus is on engineering testing machines that meet and exceed industry standards. Our dedication to precision and quality ensures that your testing requirements are always met with superior performance and reliability, including compliance with International standards like ASTM D412.

WHAT IS ASTM D412?

ASTM D412 specifically addresses the determination of tensile properties for rubber and elastomeric materials. This standard outlines the procedures for conducting tensile tests, enabling precise measurement of parameters such as tensile strength, elongation at break, and modulus. These parameters are important for assessing the material’s mechanical behavior under various loading conditions. Compounds within this class encompass a diverse array of polymers and polymer blends.

WHAT DOES ASTM D412 MEASURE?

ASTM D412 evaluates a material’s elasticity and post-test behavior following tensile strain. Tests have to be conducted on a testing machine at a controlled speed (500 ± 50 mm/min) for a distance of at least 750 mm. ASTM D412 assesses also various tensile properties, such as:

- Tensile strength.

- Tensile stress at a given elongation.

- Ultimate elongation.

- Tensile set.

ASTM D412 – TEST METHODS

ASTM D412 outlines two distinct testing methods for two different specimen types.

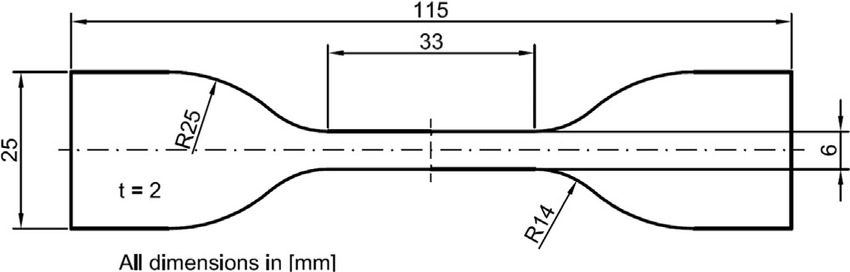

- Test Method A (most common) employs “dumbbell” or “dogbone” shaped specimens (thickness of 3.0 +/- 0.3 mm);

- Test Method B is intended for ring-shaped specimens.

The standard temperature for testing is 23 +/- 2 °C, instead, when any other temperature is required a climatic chamber can be added to the testing system.

ASTM D412 – APPLICATIONS

The ASTM D412 standard finds critical applications across diverse industries, like:

- Automotive: Rigorous testing ensures the reliability of rubber components in vehicles, from tires to gaskets.

- Aerospace: Meeting stringent safety and performance standards for elastomeric materials used in aircraft components like O-rings and gaskets.

- Manufacturing and Construction: Selecting dependable elastomeric materials for applications such as conveyor belts, industrial seals, and vibration isolators.

ASTM D412 – EXTENSOMETERS

To achieve optimal accuracy and repeatability in measurements, consider incorporating an Extensometer into the testing system. Optical (non-contact) Epsilon extensometers are particularly well-suited for elastomeric materials, especially in cases involving fragile specimens or climatic chamber testing. They offer the added advantage of reducing measurement variability attributed to operator influence, thus enhancing efficiency, particularly in high-throughput laboratory settings.

We are official distributor for Epsilon products.

TESTING MACHINES FOR ASTM D412

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test