The testing machines we design at STEP Lab allow you to perform a wide range of tests on materials and products that adhere to the strictest international standards, such as ASTM D638.

Explore what ASTM D638 is, what it measures, the test procedures, and important information about the required test equipment.

WHAT IS ASTM D638?

ASTM D638 is an important testing standard for assessing the tensile properties of both reinforced and non-reinforced plastics. This test method encompasses the determination of tensile properties for unreinforced and reinforced plastics, utilizing standard dumbbell-shaped test specimens, subject to well-defined conditions of pretreatment, temperature, humidity, and testing machine speed. It is applicable to materials of various thicknesses, up to 14 mm (0.55 in.).

WHAT DOES ASTM D638 MEASURE?

ASTM D638 involves subjecting a sample specimen to a tensile force and measuring various properties of the specimen while it’s under stress, such as tensile strenght, tensile modulus and elongation. This test is conducted using a testing machine and it applies tensile rates ranging from 1 to 500 mm/min until the specimen reaches its failure point, which could involve yielding or breaking.

Additionally, this test method provides the option of determining Poisson’s ratio at room temperature.

ASTM D638 – TEST METHOD

The test procedure consists of measuring the width and thickness of each sample, then position the specimen in the grips of the testing machine, ensuring proper alignment, and tighten the grips securely but without crushing the specimen. Eventually, connect the extension indicator using an extensometer when determining the elastic modulus is needed. Set the testing speed and start the test. Record the load-extension curve of the specimen, and document the load and extension at the yield point (if it exists) and at the moment of rupture.

ASTM D638 – SPECIMENS

Specimens used in ASTM D638 testing are typically dumbbell-shaped, with the choice of a 25 mm or 50 mm (recommended) gauge length. Specific requirements are: a 10 μm absolute accuracy for a 50 mm gauge length and a relative accuracy within ±0.5% for measuring tensile modulus of elasticity, as mandated by ASTM D638.

For elongation beyond the yield point but less than 20%, you need an absolute accuracy of 50 μm for a 50 mm gauge length and a relative accuracy within 1%. For the remainder of the test, ±10% relative accuracy is acceptable.

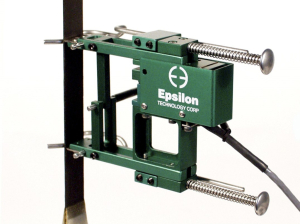

ASTM D638 – EXTENSOMETERS

For attaining the highest levels of precision and consistency in measurements, it is advisable to integrate an Extensometer into your testing setup. When it comes to plastics materials, Optical (non-contact) Epsilon extensometers prove to be exceptionally suitable. They provide an additional benefit by minimizing measurement discrepancies associated with human operators, thereby improving efficiency, especially in high-throughput laboratory environments.

As the official distributor for Epsilon products in Europe, you can find more information by clicking here to learn more about Epsilon.

TESTING MACHINES FOR ASTM D638

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test