STEP Lab manufactures fatigue testing machines for many materials and products in compliance with several international standards, including ASTM E606.

WHAT IS ASTM E606?

ASTM E606 is test method focused on determining the fatigue properties of nominally homogeneous materials through the application of uniaxial forces on test specimens. It serves as a comprehensive guide for conducting fatigue testing in various fields, including materials research and development, mechanical design, process and quality control, product performance, and failure analysis.

This standard was primarily designed for strain-controlled fatigue testing, but it can also provide valuable insights for force-controlled or stress-controlled testing. It is essential to recognize that ASTM E606 specifically addresses the testing of specimens and does not encompass the testing of full-scale components, structures, or consumer products.

ASTM E606 – TEMPERATURE AND STRAIN RATES

ASTM E606 is applicable within temperature and strain rate ranges where the magnitudes of time-dependent inelastic strains are comparable to or smaller than the magnitudes of time-independent inelastic strains. No specific restrictions are imposed on environmental factors such as temperature, pressure, humidity, and medium, as long as they are meticulously controlled throughout the test and thoroughly documented in the data report.

REQUIREMENTS OF STRAIN-CONTROLLED FATIGUE TESTING

Strain-controlled fatigue is influenced by the same variables that influence force-controlled fatigue, however imposes distinctive requirements on fatigue testing methods. In particular, cyclic total strain should be measured and cyclic plastic strain should be determined. Furthermore, either of these strains typically is used to establish cyclic limits; total strain usually is controlled throughout the cycle. The uniqueness of this test method and the results it yields are the determination of cyclic stresses and strains at any time during the tests.

IMPORTANCE OF STRAIN-CONTROLLED FATIGUE TESTING

Strain-controlled fatigue is a critical consideration in the design of industrial products, particularly when components or specific sections of components experience cyclic plastic strains induced by mechanical or thermal factors, leading to failure within a relatively low number of cycles.

ASTM E606 – TESTING MACHINE FEATURES

Testing should be performed using a tension-compression fatigue testing machine, designed to minimize backlash in the loading train, unless more stringent requirements are specified. If material behavior permits, control stability should ensure that the strain maximum and minimum limits are repeatable throughout the test duration, with a tolerance of within 1% of the range between the maximum and minimum control limits.

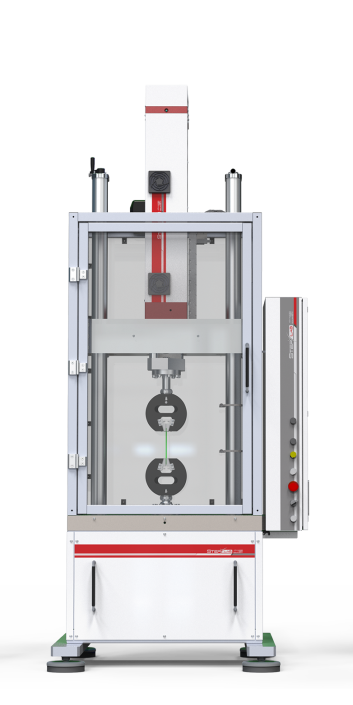

TESTING MACHINE FOR ASTM E606

Regarding this, our EA dynamic and fatigue testing machine is ideal for performing tests in compliance with ASTM E606.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test