Our testing facility prioritizes precision and reliability, specializing in engineering testing machines that surpass industry standards. We are dedicated to ensuring that your testing needs, including compliance with vital standards like EN 2597 for evaluating carbon fiber reinforced plastics (CFRP), are consistently met with unmatched performance and dependability.

WHAT IS EN 2597?

EN 2597 is a critical testing standard that delineates the method for determining essential mechanical properties of carbon fiber reinforced plastics (CFRP) in the form of unidirectional laminates. Specifically, it focuses on assessing the ultimate tensile strength, tensile modulus, Poisson’s ratio, and strain at failure in tension. This standard serves as a cornerstone for product development and quality control across various industries, including aerospace, automotive, wind energy, and construction.

EN 2597 – TEST PROCEDURE

Tensile testing according to EN 2597 involves subjecting flat test specimens to uniaxial tensile force perpendicular to the fiber direction. This process allows for the investigation of stress/strain behavior and the identification of critical material properties such as tensile modulus, tensile strength, elongation at break, and Poisson’s ratio. Tests are typically conducted using electromechanical testing machines, wherein controlled tension load is applied until failure occurs. Various measurement techniques, including contacting or non-contacting extensometers, or strain gauges, are employed to capture specimen response accurately.

WHY IS EN 2597 IMPORTANT?

The importance of adhering to EN 2597 cannot be overstated. By employing standardized testing methodologies, manufacturers can ensure consistency and reliability in material performance assessment. This is crucial for optimizing product design, enhancing structural integrity, and mitigating the risk of failure in critical applications. Moreover, compliance with EN 2597 facilitates interoperability and comparison of test results across different laboratories and research facilities, fostering advancements in material science and engineering.

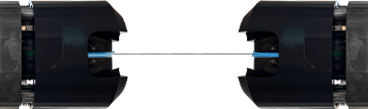

EN 2597 – EXTENSOMETERS

To achieve optimal accuracy and repeatability in measurements, consider incorporating an Extensometer into the testing system. Optical (non-contact) Epsilon extensometers are particularly well-suited for elastomeric materials, especially in cases involving fragile specimens or climatic chamber testing. They offer the added advantage of reducing measurement variability attributed to operator influence, thus enhancing efficiency, particularly in high-throughput laboratory settings.

We are official distributor for Epsilon products.

EN 2597 – TESTING SOLUTIONS

For seamless compliance with EN 2597 standards, we recommend utilizing advanced testing systems such as the Electromechanical testing machines (EA Series). This series offers versatile solutions tailored to meet diverse testing needs, available in both floor and table formats. These cutting-edge solutions offer unparalleled accuracy, reliability, and efficiency, making them indispensable tools for material characterization and evaluation.

EA SERIES FOR EN 2597

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test