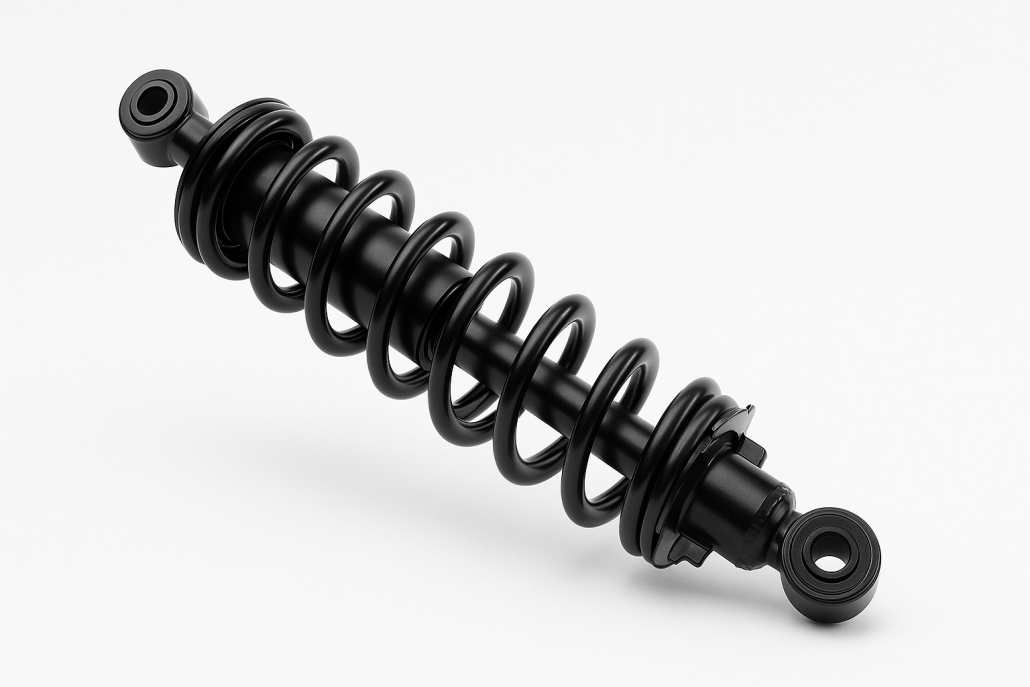

SHOCK ABSORBERS

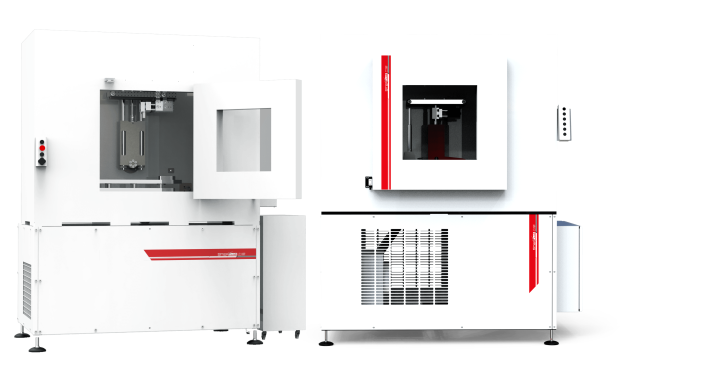

Shock absorbers play a crucial role in driving safety and comfort. For this reason, STEP Lab develops advanced test benches for the characterisation and validation of shock absorbers and suspensions, both in R&D and quality control. Our all-electric solutions allow dynamic testing with customisable profiles of travel, speed and force, including the reproduction of real road profiles.

EV BATTERIES

With the increasing popularity of electric vehicles, testing the reliability, durability and safety of lithium-ion batteries has become crucial. STEP Lab designs and manufactures advanced test systems for cells, modules and battery packs, integrating vibration, charge/discharge cycles and climate control into a single platform. Our solutions comply with major international standards, such as ISO 12405 and UN 38.3, and are designed for applications in electric cars, commercial vehicles, off-road vehicles, electric bikes and scooters.

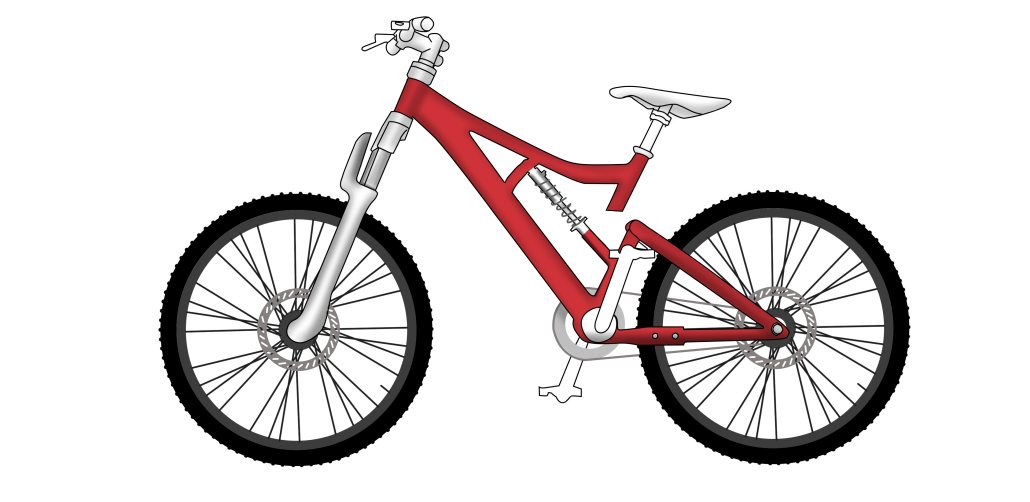

BICYCLES

In the bicycle industry, independent third-party product certification ensures that manufacturers meet safety and quality standards. This instils confidence in consumers and enables them to make informed choices when purchasing reliable and safe bicycles for their sports and leisure activities.

SPORT

Manufacturers of sports and leisure equipment must ensure that the product can withstand the intended use and possible misuse. Certification of sports equipment by an independent third party provides consumers and retailers with the assurance that the product can do what its manufacturer claims, inspiring confidence in the brand.

BIOMEDICAL

Medical device testing is a crucial step in the process of transforming an innovative project into a reliable and saleable product.

We combine the knowledge of product testing experts, providing you with a complete solution. Our testing facilities subject your product to a comprehensive evaluation of the medical device industry and help you demonstrate compliance with standards and regulations worldwide.

MATERIALS

The behaviour of materials under stress is a key aspect in ensuring the quality, safety and durability of products. STEP Lab designs advanced test systems for the mechanical characterisation of metals, polymers, composites, elastomers and other materials under static and dynamic conditions. Our solutions enable tensile, compression, flexural, fatigue and customised tests according to the main international standards.

UNIVERSITY

Education, growth and development. STEP Lab is a promoter not only in words but also in deeds by giving students the opportunity to do research and innovation in companies and not only at school. Universities lend their knowledge and their way of thinking to the scientific community and disclose their intellectual property resulting from many years of work to help others. That is why our innovative and high-performance equipment is ideal for this area.

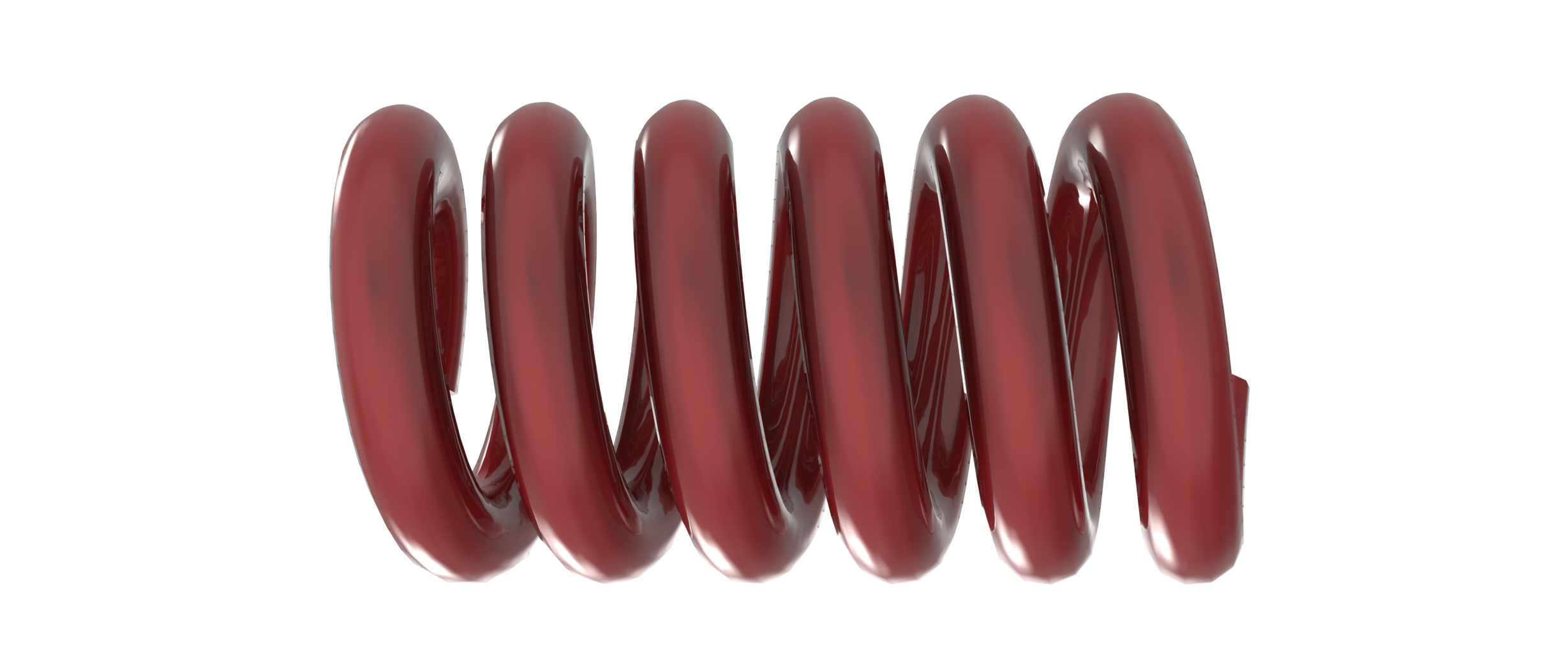

SPRINGS

Springs must be able to absorb large amounts of elastic energy, which must be released when the external force ceases to be applied.

It is mainly because of this reason that it becomes crucial to study their behaviour when subjected to one or more external forces.

STANDARDS

ASTM International is a US standards body, which stands for American Society for Testing and Materials International.

ISO, the International Organisation for Standardisation. They develop and publish international standards.

EN, European Standards are technical standards drawn up and maintained by CEN, the European Committee for Standardisation.

Other standards such as VDI and JIS.These standards ensure the consistency and reliability of processes and test results.

ASTM International is a US standards body, which stands for American Society for Testing and Materials International.

ISO, the International Organisation for Standardisation. They develop and publish international standards.

EN, European Standards are technical standards drawn up and maintained by CEN, the European Committee for Standardisation.

Other standards such as VDI and JIS.These standards ensure the consistency and reliability of processes and test results.

TESTS

The material is subjected to cyclic loading with a corresponding test frequency.

The material is subjected to unidirectional forces in a gradual manner.

These are instantaneous single-impact tests.

Technique for analysing the viscoelastic properties of materials.

Tensile, compression, creep and many other tests.