Shock Dynos Compared: Scotch-Yoke vs Electromechanical (LUD)

Shock dyno machines, are essential tools for evaluating the performance and durability of shock absorbers in various vehicles. Selecting the right type of mechanism for a shock dyno can significantly impact its accuracy, efficiency, and cost. This article explores two distinct approaches: Scotch-yoke dynos and Shock absorber testing machines with electromechanical actuators. Understanding the fundamental differences between these systems is crucial for making an informed decision about which technology best suits your testing requirements.

How do scotch-yoke systems work?

The distinction between these systems extends far beyond their basic operating principles.

The scotch-yoke mechanism centers around a rotating disk with an offset pin that engages with a sliding yoke. As the disk rotates, driven by an electric motor through a gearbox or belt drive, the offset pin moves through a circular path. The yoke, constrained to vertical movement, transforms this rotary motion into linear reciprocation. This mechanical transformation naturally produces sinusoidal motion, which has long been the standard for basic shock absorber testing. The relationship between the disk’s rotation and the yoke’s movement is fixed by the geometry of the system, creating a predictable and reliable testing pattern.

How do electromechanical shock dynos work?

Instead, electromechanical shock dynos represent the cutting edge of testing technology, employing a sophisticated combination of servo motors and precision screws. At the heart of these systems lies a servo motor that works in conjunction with a ball screw mechanism. This integration creates a direct drive system that converts rotary motion into precise linear movement. The servo motor’s rotation drives the precision screw, which in turn moves a carrier block up and down with exceptional accuracy. This carrier block, connected to the shock absorber, provides the testing motion. Modern control systems monitor and adjust the motion in real-time, allowing for complex testing profiles that can precisely replicate real-world driving conditions.

STEP Lab has brought this advanced technology to market with LUD, an innovative electromechanical shock dyno that exemplifies these principles while bridging the gap between high-end electrodynamic testing machines and simple Scotch-yoke systems. The system offers robust testing capabilities including:

- Motor power: 20/28 HP

- Peak load@Peak speed: Up to 20 kN

- Variable stroke: Up to 350 mm

- Road profiles replication

- Stroke and Speed adjustable by software

This combination of robust mechanical design and advanced control systems makes LUD an ideal solution for manufacturers seeking professional-grade shock testing without the complexity and cost of high-end test benches.

Electromechanical vs Scotch-yoke: Pros and Cons

Electromechanical solutions offer a level of control and adaptability that traditional mechanical systems struggle to match. Their direct drive approach, combined with advanced servo control, enables virtually any motion profile—an essential advantage for testing modern adaptive damping systems or developing next-generation shock absorbers. With precise force and position control throughout the stroke, these systems can replicate real-world driving conditions with unmatched accuracy. Additionally, their electronic nature allows for effortless modifications to test profiles, eliminating mechanical adjustments and making the testing process more efficient and future-proof.

- Unmatched force and position control across the stroke

- Fully customizable motion profiles for complex testing needs

- May require specialized training

- Higher initial investment

Scotch-yoke systems, on the other hand, follow a simpler, long-standing mechanical principle. Their reliability and ability to achieve high-frequency operation make them a practical choice for durability testing and high-volume production environments. However, their fixed sinusoidal motion pattern imposes inherent limitations, reducing their flexibility for modern test requirements. While they offer a lower upfront investment and simpler control requirements, their adaptability is fundamentally restricted.

- Simple, established design

- Lower upfront investment

- Rigid sinusoidal motion pattern

- Limited adaptability for advanced testing scenarios

| Feature | Scotch-Yoke | LUD |

|---|---|---|

| Stroke | Fixed / Mechanically adjustable | Fully variable via software |

| Cycle types | Sinusoidal only | Sinusoidal, triangular, etc. (software programmable) |

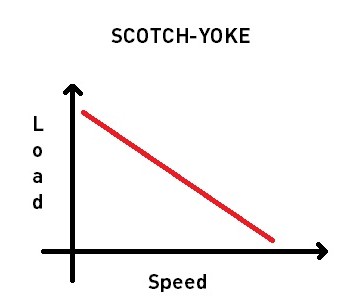

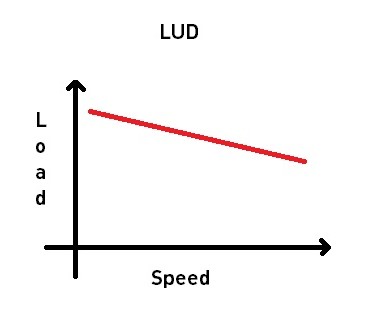

| Load vs Peak velocity |  Extremely low |  Comparable to load at maximum speed |

| Road profile reproduction | No | Yes |

| Data acquisition and control electronics | Typically low-end | Test Center by STEP Lab – same as high-end machines (HUD/XUD) |

| Available stroke | Max 100 / 150 mm | 350 mm |

| Price | From €12,000 to €25,000 | Starting from €19,900 * |

So, What Test System Do I Choose?

The choice between these two technologies should be based on a clear understanding of your testing needs and long-term objectives. As automotive testing continues to evolve, modern vehicles increasingly rely on sophisticated suspension systems that demand precise and adaptable testing solutions. Electromechanical systems stand out in development environments where adaptive damping requires comprehensive evaluation across a wide range of conditions. Their ability to replicate complex road profiles and seamlessly switch between different test patterns makes them particularly well-suited for research and innovation. >LUD Series

Budget considerations go beyond just the initial investment. While Scotch-yoke systems generally come with a lower upfront cost, the long-term financial picture is more nuanced. Electromechanical systems, despite their higher initial investment, often offset costs with lower maintenance needs and superior testing flexibility. In contrast, the mechanical simplicity of Scotch-yoke systems may lead to lower repair costs when maintenance is required, but their inherent mechanical wear can result in more frequent servicing needs over time.

Electromechanical damper testing machine – LUD

Conclusion

The choice between electromechanical and scotch-yoke shock dynos depends on a careful evaluation of testing requirements, budget constraints, and long-term testing needs.

Electromechanical systems offer unparalleled flexibility and precise control, making them ideal for sophisticated testing requirements and research applications. Scotch-yoke systems provide reliable, cost-effective testing solutions, particularly suited to high-volume production testing with consistent parameters. Understanding these factors ensures the selected system will provide the necessary testing capabilities while delivering value throughout its operational life.