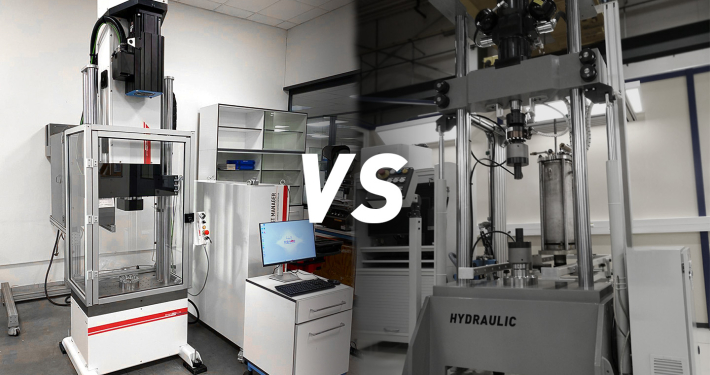

Why choose EA electromechanical systems over hydraulic machines

As the demand for more sustainable, efficient, and high-performance testing solutions grows, electromechanical systems are rapidly replacing traditional hydraulic machines. The EA Series by STEP Lab leads this evolution thanks to its cutting-edge control, high force capacity, and long-term reliability in a compact and clean package.

The limitations of hydraulic systems

Hydraulic testing machines have long been a standard in mechanical testing, but they come with significant limitations that no longer align with the priorities of modern labs and R&D environments:

- High maintenance: Regular servicing, oil changes, and component wear lead to increased downtime and costs.

- Energy inefficiency: Hydraulic pumps consume a constant amount of power (even when idle) driving up operational costs.

- Complex installation: Hydraulic systems require dedicated infrastructure, including cooling units and fluid management.

- Safety and environmental concerns: Leaks and high-pressure components can pose hazards, while hydraulic fluids require special disposal.

In applications where precision, uptime, and flexibility are critical, these systems can become more of a burden than a benefit.

Why EA electromechanical systems are the smarter choice

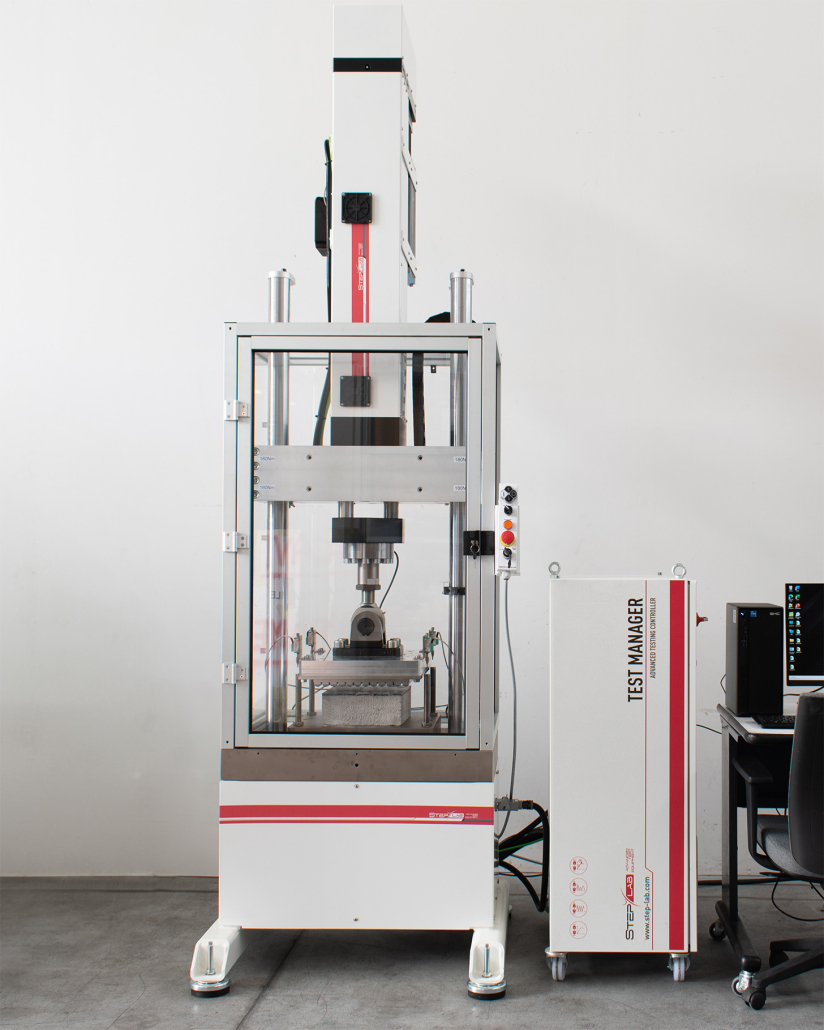

Designed with modern testing needs in mind, the EA Series from STEP Lab utilizes screw-driven actuators to deliver precise, clean, and efficient force. These systems are ideal for both static and dynamic applications and represent a long-term investment in productivity and reliability.

Key advantages of EA Series

Reduced operating costs

No fluids to replace, less frequent maintenance, and up to 70% lower energy consumption compared to hydraulic machines.

High dynamic performance

Test frequencies up to 30 Hz and force capacities from 2 to 200 kN, ideal for a wide range of mechanical tests.

Compact and clean design

EA machines occupy less space and integrate easily into any lab or production line. Moreover, they are without the mess of oil or external hydraulic units.

Maximum reliability

Electromechanical components are durable and stable over time, reducing the risk of unexpected failures.

Versatile testing capabilities

Perform tensile, compression, fatigue, cyclic, and custom testing with a single system.

Advanced control software

The integrated Test Center platform enables complete test customization, data acquisition, and real-time monitoring for any type of material or component.

| FEATURE | HYDRAULIC | ELECTRIC |

|---|---|---|

| Costs | High – maintenance-heavy | Low – minimal maintenance |

| Safety | Risk of leaks & high-pressure failures | Safe – no high-pressure fluids |

| Precision | Limited control & precision | High precision with real-time adjustments |

| Maintenance | Frequent upkeep needed | Low maintenance, fewer parts |

| Speed | Slower response | Fast response & flexible testing |

| Environmental Impact | Potential fluid leaks | Environmentally friendly, no fluid risks |

| Investment | High initial cost | Moderate setup cost |

| Testing Range | Standard tests | Broad range, including high-frequency & durability |

| Long-Term Efficiency | Expensive to operate long-term | Cost-effective over time |

Technical data

The EA Series is available in multiple configurations to match different testing needs. Below is an overview of the key technical specifications, including force range, stroke, and frequency capabilities.

| EA SERIES | EA05 | EA025 (NEW) | EA050 | EA100 | EA200 |

|---|---|---|---|---|---|

| Max. Dynamic Force | 7.50 kN | 20.00 kN | 50.00 kN | 100.00 kN | 200.00 kN |

| Max. Static Force | 15.00 kN | 18.00 kN | 65.00 kN | 139.00 kN | 268.50 kN |

| Standard Stroke | 250 mm | 250 mm | 200 mm | 200 mm | 200 mm |

| Frequency | 30 Hz | 30 Hz | 20 Hz | 20 Hz | 20 Hz |

| Length | 653 mm | 775 mm | 1100 mm | 1320 mm | 1500 mm |

| Width | 115 mm | 130 mm | 185 mm | 280 mm | 425 mm |

| Depth | 240 mm | 300 mm | 370 mm | 600 mm | 940 mm |

| Length with piston | 737 mm | 900 mm | 1250 mm | 1554 mm | 1745 mm |

| Ambient Temp. | 5 – 30 °C | 5 – 30 °C | 5 – 30 °C | 5 – 30 °C | 5 – 30 °C |

Where are they used?

The EA Series is trusted by universities, industrial labs, and research centers across the world. From material qualification to fatigue life estimation, these systems support a wide range of testing scenarios in:

- Automotive

- Aerospace

- Biomedical

- Construction materials

- Academic research

Conclusions

Hydraulic systems served their time but the future of testing is electric. STEP Lab’s EA Series offers a cleaner, more efficient, and more reliable alternative that meets the needs of today’s most advanced testing environments. If you’re looking to reduce costs, improve flexibility, and modernize your lab, it’s time to make the switch.