At STEP Lab, we are committed to delivering state-of-the-art solutions that meet the rigorous requirements of ASTM F382. Our advanced testing machines and accessories are designed to ensure the highest quality and precision in metallic bone plate testing.

Introduction to Metallic Bone Plates

Metallic bone plates are integral components in orthopedic reconstructive surgery. They provide essential alignment and fixation for two or more bone segments, ensuring proper healing while maintaining structural support. The strength and stiffness of these plates are critical, as they must withstand various mechanical stresses during the healing process.

Quantifying the bending characteristics, such as bending strength and stiffness, is crucial. These metrics offer surgeons valuable insights into the performance of bone plates and enable researchers to compare different materials and designs. Additionally, understanding the fatigue life of these devices over specific periods or ranges of maximum loading is vital for ensuring long-term reliability.

What is ASTM F382?

ASTM F382 is the standard specification and test method for metallic bone plates. It provides a comprehensive framework for classifying, defining, and measuring the geometric and performance characteristics of these plates. This standard is essential for establishing consistent methods and includes guidelines on material specifications, labeling, handling requirements, and mechanical performance testing.

ASTM F382: Testing Methods

Single Cycle Bend Testing

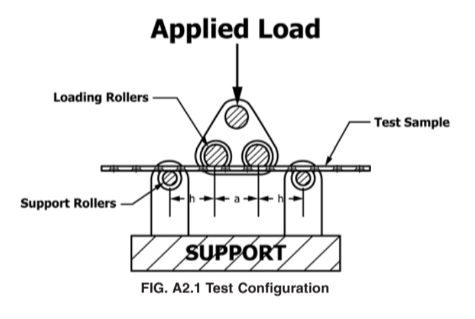

This method measures the bending stiffness, structural stiffness, and bending strength of metallic bone plates. It helps determine the intrinsic structural properties of the plates. The test setup involves placing the bone plate sample in a fixture and applying increasing loads until specific displacement measurements are recorded.

The test procedure is the following:

- Sample Preparation: Prepare samples according to the standard guidelines.

- Alignment: Place the bone plate in the test fixture, aligning its long axis perpendicular to the loading rollers’ axes.

- Load Application: Apply incremental loads and record the load versus load-point displacement curve.

Bending Fatigue Testing

This method assesses the fatigue life of bone plates under cyclic loading conditions. It evaluates how the plates perform under repeated bending stresses over time.

The procedure for fatigue testing is the following:

- Load Determination: Determine the load levels for fatigue testing.

- Sample Alignment: Place the bone plate in the test fixture, ensuring proper alignment and contact with the rollers.

- Cyclic Loading: Apply cyclic loads at a frequency (standard is 5 Hz) until the specimen breaks or the cycle count reaches the runout limit.

- Data Recording: Record the maximum moment, cycle count at test termination, failure mode, and failure location.

ASTM F382: Important Calculations

Key calculations performed during these tests include:

- Bending Stiffness: A measure of the resistance of the bone plate to bending.

- Bending Structural Stiffness: The overall rigidity of the plate.

- 2% Offset Displacement: The displacement at which the bone plate exhibits a 2% permanent deformation.

- Bending Strength: The maximum stress the bone plate can withstand before failure.

Conclusion

Understanding and adhering to ASTM F382 is essential for the development and evaluation of metallic bone plates. By following these standardized methods, researchers and medical professionals can ensure the reliability and effectiveness of bone plates used in orthopedic surgery, ultimately improving patient outcomes.

Testing machines for ASTM F382

Our UD electrodynamic and fatigue testing machine is a versatile solution for conducting tests that comply with ASTM F382.

-

- Dynamic loads range up to 100kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test