STEP Lab manufactures testing machines capable of conducting fatigue tests on materials such as plastic, while adhering to international standards like ASTM D7774.

WHAT IS ASTM D7774?

ASTM D7774 is an ASTM Standard used to determine the dynamic full reversed fatigue properties of plastics under flexural conditions. It is applicable to both rigid and semi-rigid plastics. The stress and strain levels utilized are maintained below the material’s proportional limit, ensuring that the strains and stresses remain within the relatively elastic range. Three-point or four-point bending systems are employed to ascertain these properties.

ASTM D7774 – TEST PROCEDURES

ASTM D7774 presents two different test methods:

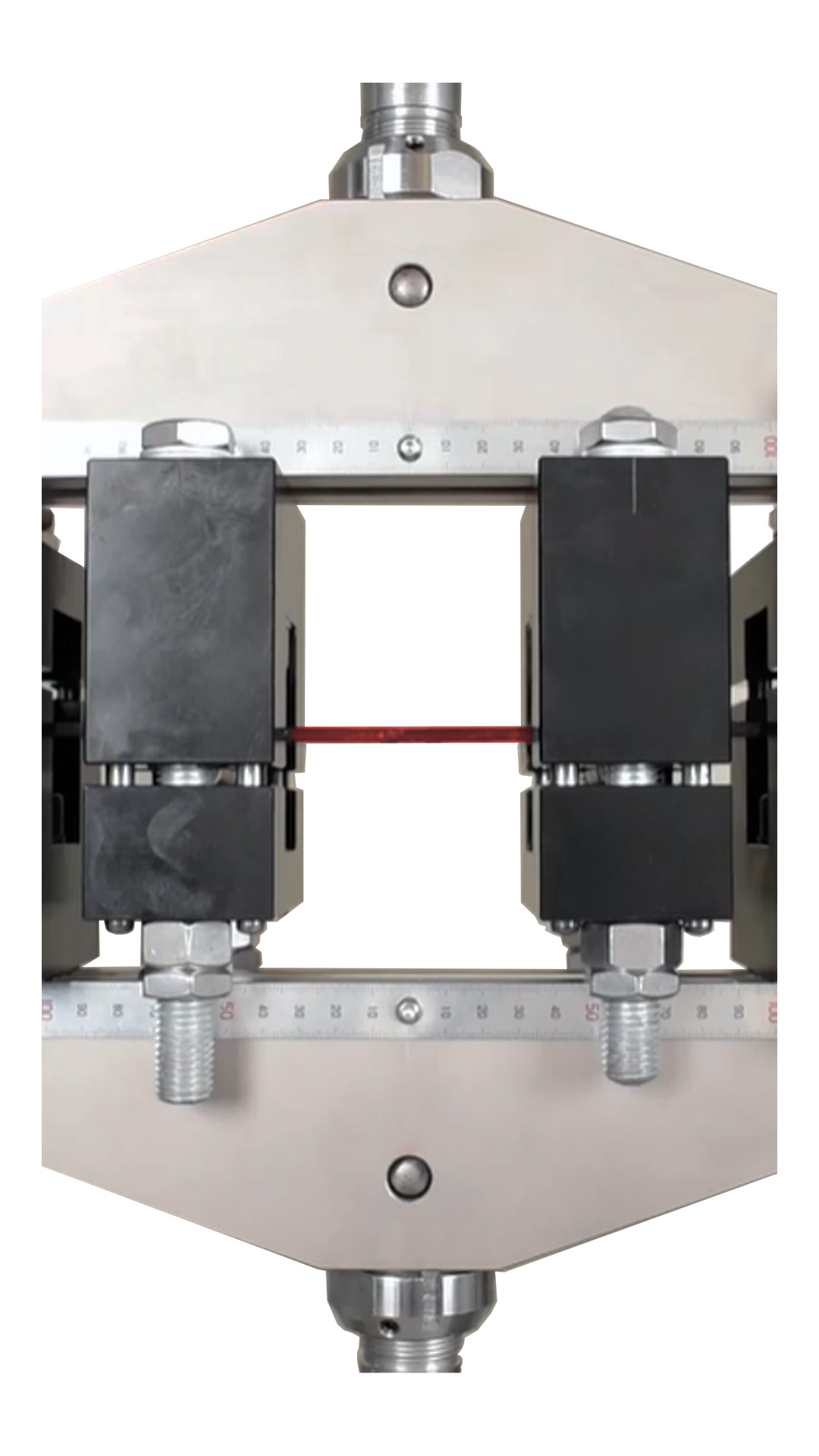

- Procedure A: In this procedure, a rectangular cross-section specimen is supported by two double-sided supports, and it is loaded using a double-sided loading nose positioned midway between the supports. A support span-to-depth ratio of 16:1 is utilized. The specimen undergoes cyclic loading in both positive and negative directions at a uniform frequency until it either ruptures or yields, while maintaining a specific stress or strain level. This procedure aims to determine the flexural endurance limit of the material.

- Procedure B: Like the procedure A, with the only difference on the load span-to-support span ratios that can be either 1:2 or 1:3.

NOTE: These procedures allow for various specimen preparation techniques. However, it is important to note that results obtained from specimens prepared differently should not be considered comparable unless equivalency has been demonstrated.

ASTM D7774 – PURPOSE

The purpose of ASTM D7774 is to evaluate the impact of processing, surface condition, stress, and other factors on the fatigue resistance of plastic materials under flexural stress for a significant number of cycles. These tests provide valuable information for selecting appropriate plastic materials to withstand repeated flexural stress in specific service conditions.

It is important to note that properties can vary depending on the specimen depth and test frequency. While the test frequency can range from 1 to 25 Hz, it is recommended to use a frequency of 5 Hz or lower.

ASTM D7774 – ADDITIONAL NOTES

It is crucial to consider that material response to fatigue differs among various plastics. If a plastic lacks an elastic region where strain is reversible, plastic deformation occurs during fatigue testing, leading to changes in the amplitude of the programmed load or deformation throughout the test. Therefore, when using the test results for design purposes, caution must be exercised as they may not accurately reflect the true fatigue properties of the material.

The results obtained from these fatigue tests are suitable for design applications only if the specimen test conditions realistically simulate the actual service conditions, or if there is a clear and defined methodology to account for the service conditions.

TESTING MACHINES FOR ASTM D7774

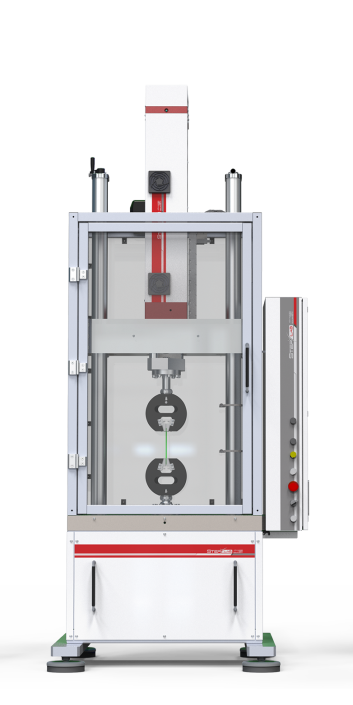

Our EA dynamic and fatigue testing machine is ideal for performing static and cyclic tests in compliance with ASTM D7774. It serves as a versatile solution for conducting tests that demand precise and swift control over force and position.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test