ASTM D2344 is a standard test method used to determine the short beam strength of polymer matrix composite materials. This test provides essential data on the interlaminar shear strength of composite laminates, helping engineers and manufacturers assess material performance under shear loading conditions.

What is ASTM D2344?

ASTM D2344 defines the procedure for conducting short beam shear tests on polymer matrix composites. The test involves applying a three-point bending load to a small specimen, measuring its response to shear stress. The short beam shear test is widely used in industries such as aerospace, automotive, and industrial manufacturing, where composite materials must exhibit strong interlaminar properties. This method is often used for quality control and material selection, as it provides insights into how different composite layups and manufacturing processes affect shear strength.

What Does ASTM D2344 Measure?

This test method evaluates the interlaminar shear strength (ILSS) of composite laminates, a key parameter that determines the ability of the material to resist shear forces that can cause delamination. The test results help engineers assess the performance of composites under mechanical stress, ensuring that the material will perform as expected in demanding applications. The data collected from ASTM D2344 testing is used in the design and validation of composite structures, helping manufacturers select the best material configurations for their specific needs.

Why is ASTM D2344 Important?

- Material Qualification: Ensures that composite materials comply with industry standards and perform reliably in real-world applications.

- Quality Control: Helps manufacturers monitor production consistency and detect defects in composite laminates before they are used in critical applications.

- Structural Integrity: Provides essential data for engineers to optimize composite design, preventing failures due to weak interlaminar bonding.

- Comparative Analysis: Allows for the comparison of different composite formulations, helping manufacturers develop improved materials with enhanced shear resistance.

ASTM D2344 Test Methods

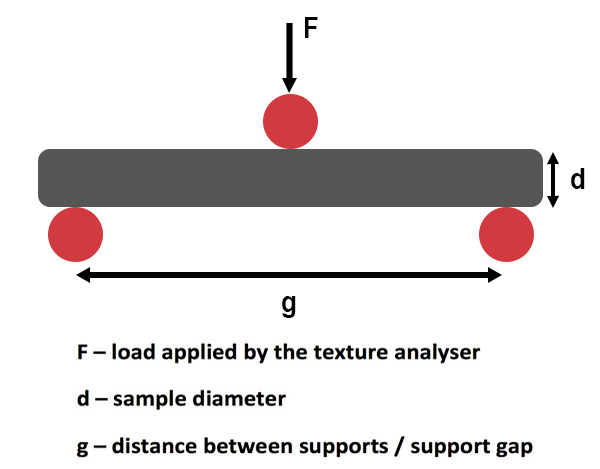

The test involves placing a rectangular composite specimen on two support spans and applying a load at the center until failure occurs. The force required to cause delamination or breakage is recorded and used to calculate the interlaminar shear strength of the material.

Key factors influencing the test results include:

- Specimen Dimensions: Proper sample preparation is essential to ensure accurate and repeatable results.

- Support Span-to-Thickness Ratio: A typical ratio of 4:1 is used to minimize bending effects and ensure that shear failure occurs.

- Loading Rate: The speed at which the force is applied can impact test outcomes, so standardized rates must be followed.

- Failure Mode Analysis: Understanding whether failure is due to delamination, fiber breakage, or matrix cracking helps in material assessment.

TESTING MACHINES FOR ASTM D2344

STEP Lab provides high-performance electromechanical testing machines (EA Series) optimized for ASTM D2344. Our systems ensure precise load application and data acquisition, meeting the highest industry standards.

For more information about ASTM D2344 testing solutions, contact us today!