HOW TO CHOOSE THE RIGHT ACTUATOR FOR YOUR TESTING

Selecting the appropriate actuator is a crucial step in designing effective and reliable testing systems. The choice depends on the type of tests you perform, the specific requirements of your application, and the characteristics of the actuator itself. This guide will walk you through the key factors to consider and compare two popular options: Electromechanical and electrodynamic actuators.

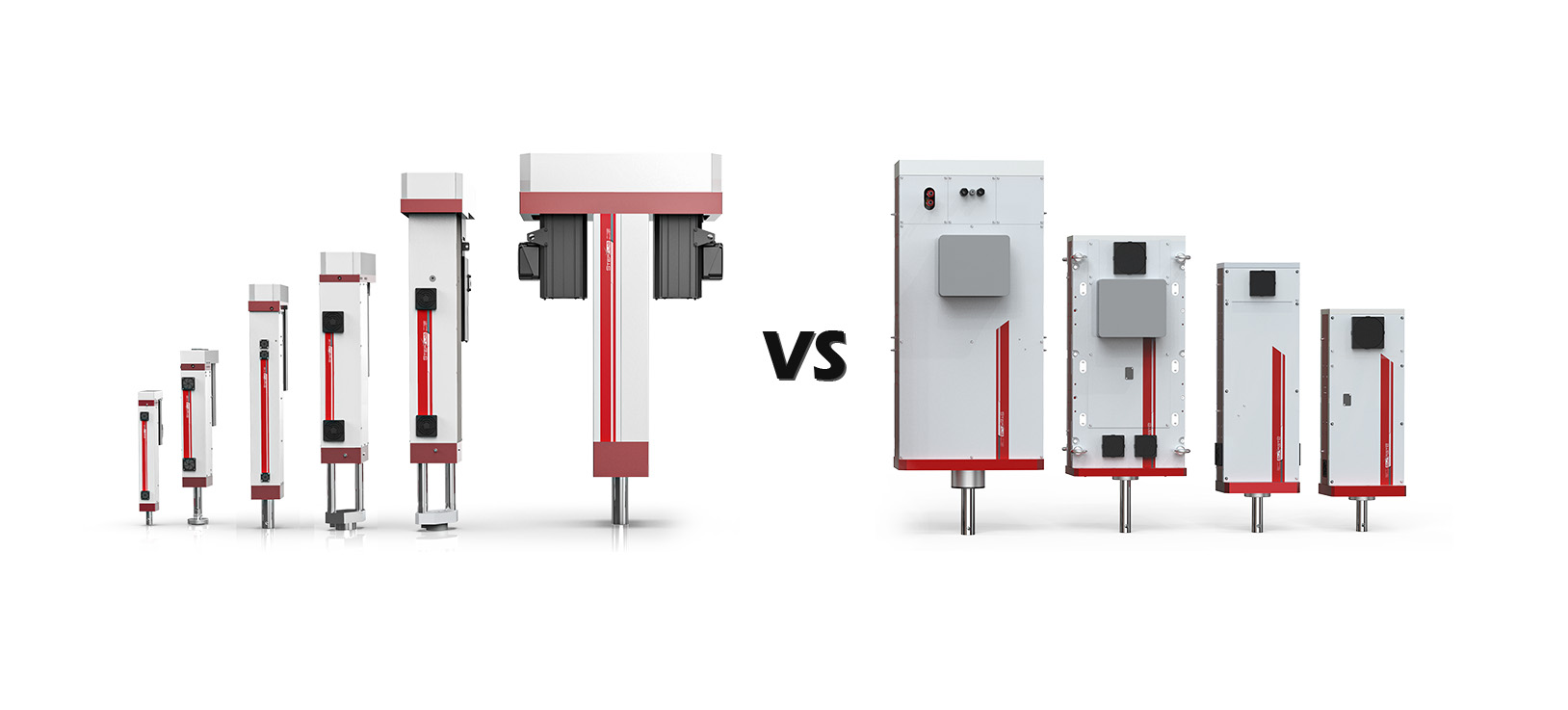

Electromechanical vs Electrodynamic actuators

The selection of an appropriate actuator for a testing system represents a critical design decision with direct implications for test accuracy, repeatability, and overall system performance. The actuator serves as the central element that defines the system’s dynamic/static capabilities.

The two main technologies are:

- Electromechanical actuators (based on ball screw mechanisms)

- Electrodynamic actuators (based on linear motors)

Each offers distinct advantages and limitations. This guide will help you understand the differences and make the best choice for your test needs.

Understanding the two technologies

Electromechanical actuators (Ball screw type)

Electromechanical actuators use a rotating motor connected to a precision ball screw that converts rotary motion into linear movement. These systems are highly controllable, energy efficient, and robust. They are widely used in structural testing, fatigue testing, and in any application requiring precise displacement or force over long durations.

Key features:

- High force capacity

- Precise control at low speed

- Longer stroke capabilities

- Lower power consumption

Electrodynamic actuators (Linear motor type)

Electrodynamic actuators produce direct linear motion without any mechanical transmission elements. The force is generated by a magnetic field acting on a moving coil or magnet. These systems excel at high-speed, high-frequency applications where fast response and low inertia are critical.

Key features:

- High dynamic response (up to 1000 Hz)

- Low maintenance due to no mechanical contact

- Ideal for vibration, impact, or NVH testing

- Compact and clean design

- Requires active cooling and high-power electronics

Side-by-side comparison

| FEATURE | Electromechanical | Electrodynamic |

|---|---|---|

| Force output | Very high | Moderate (best for dynamic loads) |

| Speed | Moderate | Very high (excellent for dynamic tests) |

| Frequency range | Up to 30-50 Hz | Up to 1000 Hz |

| Stroke lenght | Long strokes available | Short to medium strokes |

| Control accuracy | Excellent at low speeds | Excellent at high speeds |

| Energy efficiency | High (only consumes energy when in motion) | Moderate |

| Noise | Low | Moderate |

| Cooling | Air | Air/Water |

| Maintenance needs | ||

| Environmental impact | ||

| Cost | ||

When to choose electromechanical actuators

Opt for electromechanical actuators if:

- You need high force output for static, quasi-static, or fatigue testing.

- Your test requires long strokes with precise control over displacement.

- The system will run for long durations, such as 24/7 fatigue or creep testing.

- Energy efficiency and cost containment are priorities.

- You’re testing mechanical assemblies, structures, or polymers with long displacement ramps.

At STEP Lab, our EA series of electromechanical actuators are used worldwide for static and fatigue tests across aerospace, automotive, and material science applications.

When to choose electrodynamic actuators

Choose electrodynamic actuators if:

- You need to simulate dynamic events: vibration, shocks, impacts, or road profiles.

- Your application requires high frequency, such as up to 1000 Hz.

- You want frictionless, backlash-free motion with minimal maintenance.

- Your testing involves NVH, seat testing, or damper/suspension evaluation.

- You prioritize cleanroom compatibility, low noise, and smooth motion.

Our UD series electrodynamic actuators form the base for all high-speed systems we deliver, including: HUD, KUD and XUD. These systems are trusted for advanced durability and dynamic simulations, offering unparalleled response speed and accuracy.

Conclusion

There’s no universal winner when it comes to choosing between electromechanical and electrodynamic actuators. Your test profile, performance requirements, and budget will determine the right technology.

- Electromechanical actuators are ideal for high loads, low frequencies, static or dynamic testing. They combine precision, efficiency, and lower maintenance in a robust and scalable design.

- Electrodynamic actuators excel in high-speed, high-frequency dynamic testing where responsiveness and control accuracy are critical. With no mechanical wear components, they offer silent, clean, and nearly maintenance-free operation.

At STEP Lab, we design and manufacture both technologies to fit your exact needs, from standard systems to fully customized test benches. If you’re planning your next test setup or need guidance on actuator selection, our team of engineers is here to help.

FAQ

1. What is the primary difference between electromechanical and electrodynamic actuators?

Electromechanical actuators are designed for precision and stability in static and slow cyclic tests, using motors and screws to generate motion. Electrodynamic actuators, on the other hand, are optimized for high-speed, dynamic applications, relying on electromagnetic coils for rapid and responsive movements.

2. Which type of actuator is better for high-frequency fatigue testing?

Electrodynamic actuators are better suited for high-frequency fatigue testing due to their ability to operate at high speeds and simulate dynamic real-world conditions such as vibrations and impacts.

3. Are electromechanical actuators more energy-efficient than electrodynamic ones?

Yes, electromechanical actuators are generally more energy-efficient, particularly for static and slow-speed applications. Electrodynamic actuators consume more energy, especially at higher frequencies.

4. Can electromechanical actuators handle dynamic applications?

While electromechanical actuators can handle some dynamic applications, they are not ideal for high-speed or high-frequency tasks. For such scenarios, electrodynamic actuators are more suitable.

5. Can STEP Lab’s actuators be customized for specific applications?

Yes! At STEP Lab, we offer customizable electromechanical and electrodynamic actuators designed to meet the unique needs of our clients. Contact us to discuss your testing challenges and discover how we can help.