ISO 4210 COMPLIANCE MADE EASY: THE ULTIMATE SOLUTION FOR BICYCLE FRAME TESTING

In the rapidly evolving world of cycling, the safety and durability of bike components are of paramount importance. With the increasing demand for high-performance bicycles, especially those made from advanced materials like carbon fiber and aluminum, rigorous testing is essential. To meet these demands, manufacturers must adhere to international standards that ensure the reliability of their products. One such solution is a universal test bench designed to perform a variety of static and fatigue tests on bicycle frames, adhering to standards such as ISO 4210-6 and EN 15194.

WHAT DOES THIS UNIVERSAL TEST BENCH CONSIST OF?

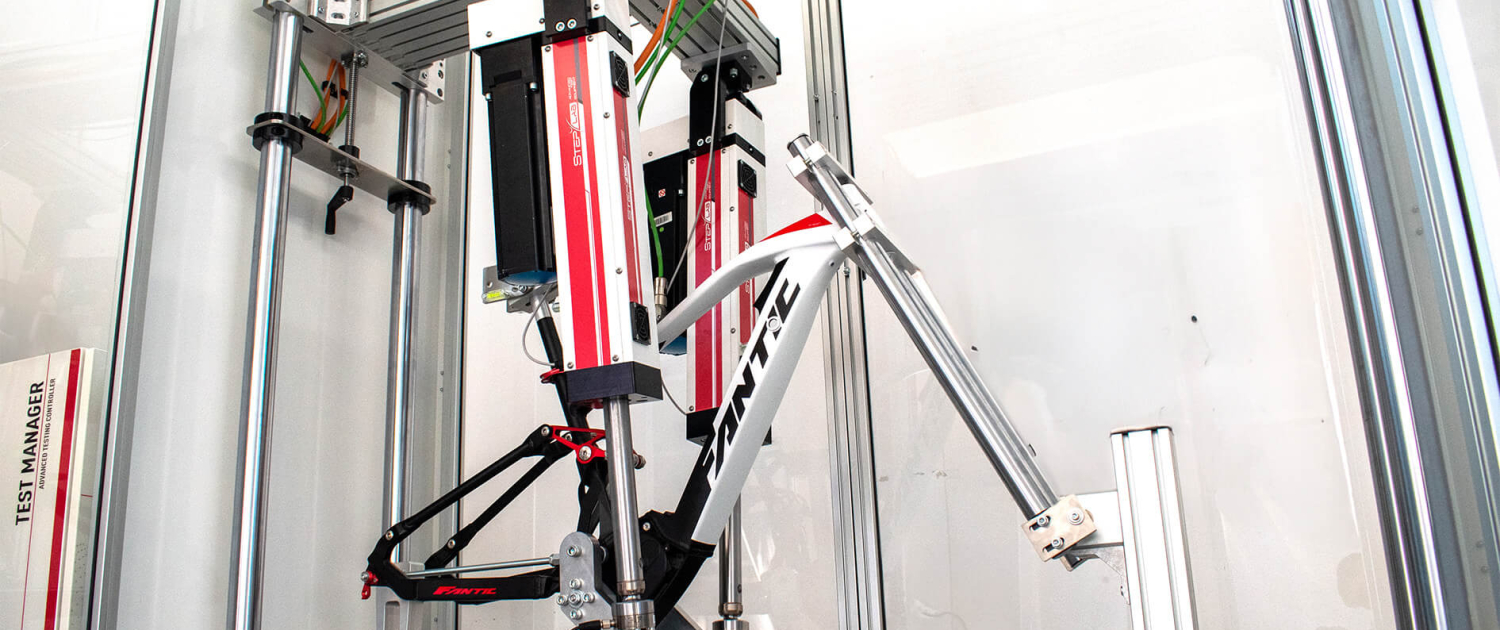

The universal solution for bicycle frame testing is a highly adaptable system designed to evaluate the structural integrity and longevity of bike frames. This test bench is specifically engineered to conduct static and fatigue tests on frames made from carbon fiber and aluminum, two of the most common materials in high-end bicycles. The testing process aligns with the rigorous requirements set forth by international standards like ISO 4210-6 and EN 15194, ensuring that bicycles are safe for consumers.

Universal bike testing machine compliant with ISO 4210 – Biaxial configuration

FEATURES OF THE UNIVERSAL TEST BENCH

One of the standout features of this test bench is its versatility. It is not limited to just one type of test or one component of the bicycle. With the appropriate additional fixtures, the same system can perform both biaxial and single-axis testing required by other bike testing standards, including:

- Handlebar and Steering Testing (ISO 4210-5): Ensures that the handlebars and steering mechanisms can withstand the forces encountered during use.

- Fork Testing (ISO 4210-6): Assesses the strength and durability of the bike’s fork, a critical component for rider safety.

- Saddles and Seat-post Testing (ISO 4210-9): Verifies that the saddle and seat post can endure the stresses they are subjected to during riding.

- Pedal and Drive System Testing (ISO 4210-8): Confirms the robustness of the pedals and drivetrain, crucial for efficient power transfer.

The system supports three primary test configurations for bike frames, with the flexibility to accommodate more:

- Pedaling Configuration: Utilizes two actuators pushing on the pedals to simulate the forces experienced during pedaling (ISO 4210-6 4.3 and EN 15194 4.3.7.4).

- Saddle Configuration: Involves one actuator applying force on the seat tube to test the frame’s response (ISO 4210-6 4.5 and EN 15194 4.3.7.6).

- Fork Configuration: The frame is pulled horizontally to evaluate the fork’s performance under stress (ISO 4210-6 4.4 and EN 15194 4.3.7.5).

ADVANTAGES OF THE UNIVERSAL SOLUTION

The universal test bench offers several key advantages:

- Flexibility: The ability to switch between different test configurations and standards with ease makes this system highly adaptable to various testing needs.

- Comprehensive Testing: It ensures that all critical components of the bicycle are thoroughly tested, from the frame to the drivetrain, providing a holistic assessment of the bike’s performance.

- Efficiency: By consolidating multiple tests into one system, manufacturers can save time and resources, improving their overall testing process.

- Accuracy: Advanced software monitoring allows for precise tracking of displacement trends and automatic detection of any failure that occurs during testing, ensuring the highest levels of safety and reliability.

APPLICATIONS OF THE UNIVERSAL TEST BENCH

This versatile testing solution is ideal for a range of applications in the bicycle industry:

- Bicycle Manufacturers: For conducting in-house testing to ensure compliance with international safety standards.

- Testing Laboratories: To offer comprehensive testing services to various bicycle brands and manufacturers.

- Research and Development: For developing and refining new bicycle models, particularly those utilizing cutting-edge materials like carbon fiber.

- Quality Assurance: To verify the durability and performance of bicycles before they reach the consumer market.

CONCLUSION

The universal solution for bicycle frame testing represents a significant advancement in ensuring the safety and reliability of modern bicycles. By providing a flexible, comprehensive, and efficient testing system, it enables manufacturers and testing laboratories to meet the stringent requirements of international standards, ensuring that every bicycle is safe and durable for riders. As the cycling industry continues to innovate, this universal test bench will play a crucial role in maintaining high standards of quality and performance.