At STEP Lab, we specialize in manufacturing testing systems designed to conduct a multitude of tests adhering to global standards and regulations. Embracing quality and precision, our equipment ensures compliance with esteemed standards like ISO 14126, setting the benchmark for accurate and reliable testing in the industry.

WHAT IS ISO 14126?

ISO 14126 is the standard governing the assessment of in-plane compressive properties of fiber-reinforced plastic composites. Encompassing precise methodologies and protocols. ISO 14126 serves as a cornerstone for industries reliant on composite materials.

WHAT DOES ISO 14126 MEASURE?

The primary objective of ISO 14126 is to quantify the in-plane compressive properties of fiber-reinforced plastic composites. These properties include compressive modulus, compressive strength, and compressive failure strain, which are instrumental in determining the material’s performance under compressive loads.

ISO 14126 – HOW TO PERFORM A TEST

To perform a test in accordance with ISO 14126 entails meticulous preparation and adherence to standardized procedures. The standard outlines two distinct methods for evaluating the compressive properties:

- Method 1 – Entails shear loading of the specimen. This approach involves subjecting the specimen to compressive forces along its major axis. To execute Method 1 effectively, a specialized fixture, such as the Celanese-type fixture, is utilized. This fixture provides the necessary support for the specimen during compression.

- Method 2 – Offers flexibility by allowing for end loading or mixed loading of the specimen. While less common than Method 1, this approach accommodates different testing scenarios and requirements.

The choice between Method 1 and Method 2 hinges upon the specific objectives of the evaluation.

ISO 14126 – EQUIPMENT AND SETUP

Compliance with ISO 14126 requires the use of specific testing equipment and careful setup procedures for both methods outlined in the standard. In Method 1, the Celanese-type fixture is commonly chosen due to its widespread use and established reliability. Conversely, Method 2 necessitates fixtures capable of accommodating various loading configurations, highlighting the importance of versatile equipment selection.

Given the significant forces involved in testing, it is advisable to employ a dual-column electromechanical testing system. This system enables precise control and measurement, ensuring consistent compression at a steady displacement rate until the specimen fractures. By promoting uniformity in testing conditions, this setup enhances the reliability and accuracy of results.

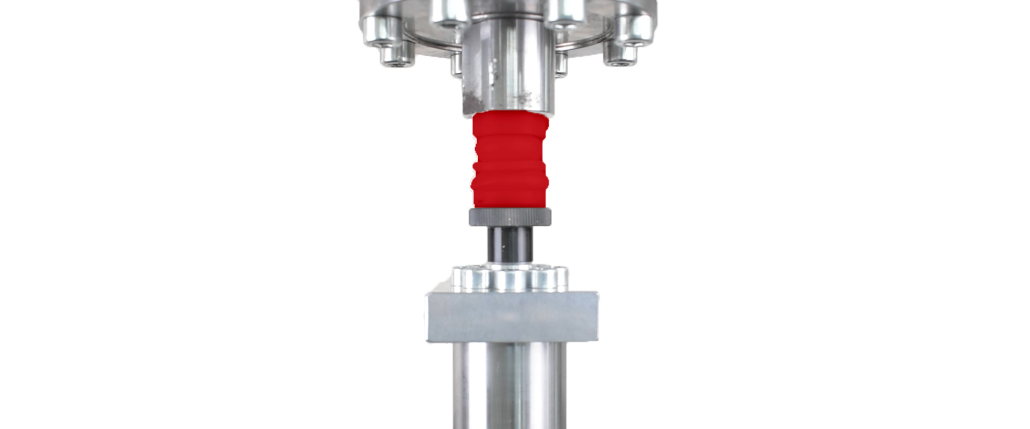

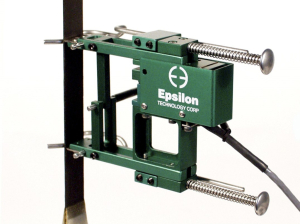

Critical to the evaluation process is the accurate measurement of strain, which is essential for determining key parameters such as compressive modulus and compressive failure strain. To measure the axial strain during the test, it is essential to use extensometers or bonded resistance strain gauges.

TESTING MACHINE FOR ISO 14126

At STEP Lab, our EA Series comprises the machines for executing tests in accordance with ISO 14126. Covering a load range from 200 N to 268 kN, these systems ensure precise control over compression parameters, guaranteeing reproducible and accurate results. Our electromechanical test systems are available in various models, offering variable loads, speeds, high-quality load frames, and intelligent drive systems to meet diverse testing needs.

Conduct tests in adherence to ISO 14126 standards with our EA Series, featuring:

- No maintenance

- Easy installation

- Low energy consumption

- Certified results

For more information on our impact test systems, click the button below.