At STEP Lab, we specialize in manufacturing a diverse range of testing machines, including drop towers that are capable of conducting various tests in accordance with international standards and regulations, such as ISO 179-1 and ISO 179-2.

WHAT IS ISO 179-1?

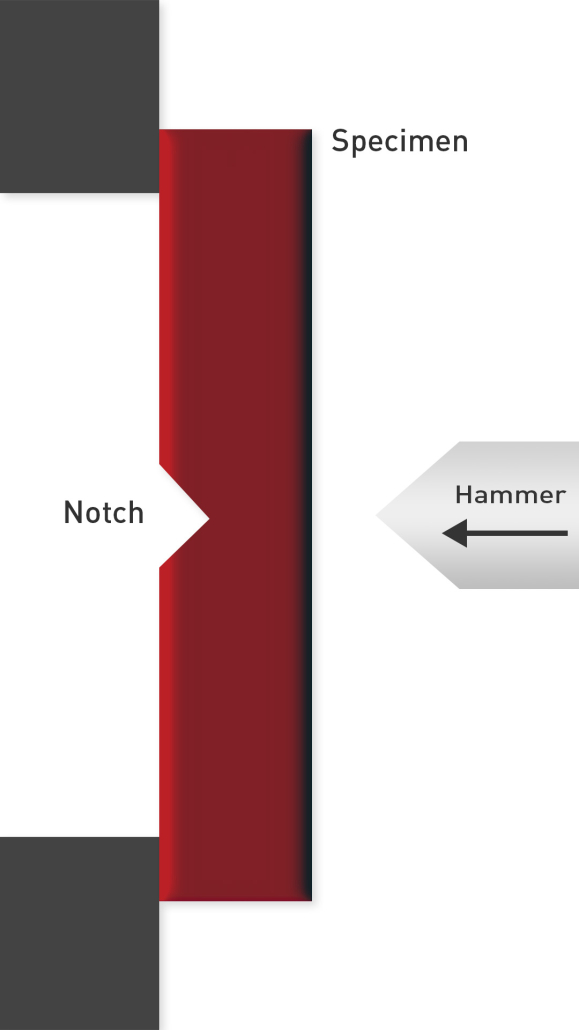

ISO 179-1, the first part of ISO 179, focuses on non-instrumented impact tests. It provides a standardized method for determining the Charpy impact strength of plastics under specific conditions.

The standard defines different types of specimens and test configurations, with specific parameters based on factors such as material type, specimen type, and notch type.

ISO 179-1 is suitable for evaluating impact behavior solely based on impact strength and for utilizing apparatus whose potential energy closely matches the energy required for fracture.

WHAT IS ISO 179-2?

On the other hand, ISO 179-2, the second part of ISO 179, addresses instrumented impact tests. It outlines a method for determining the Charpy impact properties of plastics by analyzing force-deflection diagrams.

ISO 179-2 is particularly useful when a detailed characterization of impact behavior is required through force-deflection or force-time diagrams.

Additionally, this standard aids in the development of automatic apparatus, eliminating the need for precise energy matching as mentioned earlier.

At STEP Lab, we ensure that our impact testing machines are designed to meet the specifications outlined in ISO 179-1 and ISO 179-2, enabling accurate and reliable testing of plastics’ impact properties.

TESTING MACHINES FOR ISO 179-1 and ISO 179-2

Our Drop Towers provide the ideal solution for conducting such tests. Key features of our Drop Towers include:

- Impact velocity up to 5.0 m/s (up to 20 m/s with spring preload system);

- Set of standard drop weights: weights from 0.5 to 10 kg, a total of 70 kg;

- Impact velocity acquisition at 200 kHz;

- Force signal acquisition rate up to 10 MH.

For more detailed information about our drop weight towers, click the button below.