WHAT IS ISO 527-3?

ISO 527-3 is an international standard used to evaluate the tensile properties of plastic films or sheets. In this standard, film or sheeting is defined as a plastic test specimen with a thickness less than 1 mm. If the plastic exceeds a thickness of 1 mm, testing should be carried out in accordance with ISO 527-2.

These materials are crucial in the packaging industry and serve as integral components in complex products, such as electric vehicle batteries.

WHAT DOES ISO 527-3 MEASURE?

ISO 527-3 is utilized for assessing diverse tensile properties, with the following being the most prevalent:

- Tensile strength

- Tensile modulus

- Elongation

- Strain

- Poisson’s Ratio

ISO 527-3 – HOW TO PERFORM A TEST

The ISO 527-3 testing protocol involves the systematic application of a controlled tensile force to a standardized sample using a universal testing machine. This machine is equipped with a crosshead that moves at a specified rate. As the machine subjects the specimen to tension, various properties of the material are quantified, including its response to stress, strain, and deformation. The test progresses until the specimen either undergoes yielding, indicating permanent deformation, or reaches its breaking point. Throughout this process, data such as force, elongation, and other pertinent parameters are gathered and examined to characterize the material’s tensile properties.

ISO 527 – THE 5 STANDARDS

The ISO 527 series consists of five standards, with ISO 527-1 serving as the foundational principle referred to by ISO 527-2 through ISO 527-5. ISO 527-1 sets forth the fundamental guidelines for assessing the tensile properties of plastic materials under defined conditions. The standard outlines different testing geometries, offering a comprehensive framework. It’s crucial to choose the relevant ISO 527 standard corresponding to the specific material being evaluated. The five standards in the ISO 527 series are as follows:

- ISO 527-1: Plastics – Determination of Tensile Properties

- ISO 527-2: Test conditions for moulding and extrusion plastics

- ISO 527-3: Test conditions for films and sheets

- ISO 527-4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites

- ISO 527-5: Test conditions for unidirectional fibre-reinforced plastic composites

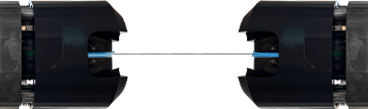

ISO 527-3 – EXTENSOMETERS

To achieve optimal accuracy and repeatability in measurements, consider incorporating an Extensometer into the testing system. Optical (non-contact) Epsilon extensometers are particularly well-suited for elastomeric materials, especially in cases involving fragile specimens or climatic chamber testing. They offer the added advantage of reducing measurement variability attributed to operator influence, thus enhancing efficiency, particularly in high-throughput laboratory settings.

We are official distributor for Epsilon products.

TESTING MACHINES FOR ISO 527-3

Thin film specimens, breaking at relatively low forces, are commonly subjected to ISO 527-3 testing using a universal testing machine. STEP Lab’s EA and UD Series testing machines are ideal for conducting tests in accordance with ISO 527-3, as they boast a variety of test frames specifically designed for thin film testing.

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test