At STEP Lab, we specialize cutting-edge testing systems that adheres to the most rigorous international standards, like ISO 6603. This standard plays a crucial role in assessing the puncture impact behavior of rigid plastics. Whether you’re involved in plastics manufacturing or quality control, understanding ISO 6603 is essential for ensuring product integrity and performance.

WHAT IS ISO 6603?

ISO 6603 is an international standard designed to assess the puncture impact behavior of rigid plastics, falling within the broader category of “Plastics — Determination of Puncture Impact Behaviour of Rigid Plastics.” Consisting of two main parts, ISO 6603-1 and ISO 6603-2, the standard provides distinct methods for evaluating the impact resistance of plastic materials.

ISO 6603-1 involves non-instrumented impact testing, while ISO 6603-2 focuses on instrumented impact testing, both offering valuable insights into the performance of plastics under specific testing conditions. These standards are applicable to a wide range of materials, including thermoplastics, thermosets, and composites.

WHAT DOES ISO 6603 MEASURE?

ISO 6603 measures the puncture impact behavior of rigid plastics through standardized testing procedures.

- In ISO 6603-1, which involves non-instrumented impact testing, the standard specifies methods for determining the puncture-impact properties of rigid plastics in the form of flat test specimens under defined conditions. This includes assessing the behavior of plastic sheeting or moldings when subjected to the impact of a striker applied perpendicularly to the plane of the specimen.

- ISO 6603-2, focusing on instrumented impact testing, determines puncture impact properties using instruments to measure force and deflection. This part is crucial when a detailed characterization of the impact behavior, represented by force-deflection or force-time diagrams recorded at constant striker velocity, is necessary.

In essence, ISO 6603 serves as a comprehensive tool for quantifying and understanding how rigid plastics respond to puncture impact under various conditions, providing valuable data for industries relying on these materials in their applications.

ISO 6603 – FIRST PART

This International Standard outlines methods for determining the puncture-impact properties of rigid plastics in the form of flat test specimens, such as discs or square pieces, under defined conditions. Specimens may be directly molded, cut from sheets, or obtained from finished products. Various types of test specimens and conditions are defined. These falling-dart methods are employed to study the behavior of plastic sheeting or moldings when subjected to the impact of a striker applied perpendicular to the specimen’s plane. ISO 6603-1 is suitable for characterizing the impact behavior of plastics by a threshold value of impact-failure energy based on multiple test specimens.

These methods are appropriate for use with the following types of materials:

- Rigid thermoplastic molding and extrusion materials, including filled, unfilled, and reinforced compounds and sheets;

- Rigid thermosetting molding and extrusion materials, including filled and reinforced compounds, sheets, and laminates;

- Fiber-reinforced thermoset;

- Thermoplastic composites incorporating unidirectional or non-unidirectional reinforcements such as mats, woven fabrics, woven rovings, chopped strands, combination and hybrid reinforcements, rovings, milled fibers, and sheets made from pre-impregnated materials (prepregs).

These methods are also applicable to specimens that are either molded or machined from finished products, laminates, and extruded or cast sheets.

ISO 6603-1: TEST METHODS

Two statistical methods of testing are described in this part of ISO 6603:

- Method A: Staircase Method (individual): In this method, a uniform energy increment is employed during testing. The energy is decreased or increased by the uniform increment after testing each specimen, depending on the observed result (pass or fail) for the preceding test.

- Method B: Group Method (optional): In this method, successive groups of at least ten test specimens are tested. The impact failure energy is calculated using statistical analysis.

ISO 6603 – SECOND PART

ISO 6603-2 outlines a test method designed for the determination of puncture impact properties of rigid plastics, specifically in the form of flat specimens. It utilizes instruments to measure both force and deflection. This method becomes relevant when a detailed characterization of the impact behavior is required, necessitating the recording of a force-deflection or force-time diagram at a nominally constant striker velocity.

ISO 6603-2 is utilized when a force-deflection or force-time diagram, recorded at nominally constant striker velocity, is required for a detailed characterization of the impact behavior. These test methods are applicable to specimens with a thickness ranging from 1 mm to 4 mm.

ISO 6603-2: TEST PRINCIPLE

The test involves puncturing the center of the test specimen with a lubricated striker, oriented perpendicularly to the specimen’s surface and at a nominally uniform velocity. The resulting force-deflection or force-time diagram is electronically recorded. The test specimen may be clamped in position during the test. The force-deflection diagram obtained through these tests captures the impact behavior of the specimen, providing insights into various features of the material’s behavior. For consistent results, the test should be conducted under constant conditions, requiring a minimum of five test specimens or, in cases of arbitration, 10 specimens.

TESTING SYSTEMS FOR ISO 6603

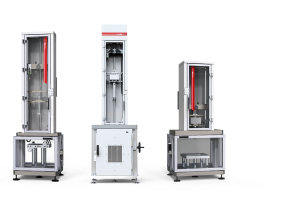

To comply with ISO 6603-1 and ISO 6603-2 testing standards, STEP Lab has engineered the DW Series, a set of drop weight towers (standard and custom). This tower is designed to conduct a versatile range of tests with precision and accuracy.

The essential components are:

- Energy Carrier: Inertial-mass type or hydraulic type;

- Striker: Lubricated for smooth operation;

- Specimen Support: Equipped with a recommended clamping device.

The test device must facilitate the puncturing of the test specimen at its center, maintaining a perpendicular orientation to its surface at a nominally constant velocity. Both the force exerted on the test specimen in the direction of impact and the deflection from the center of the test specimen in the impact direction should be derivable or measurable.

Our drop weight towers are a versatile solution for conducting impact tests that require high accuracy and speed.

-

- Impact energy range from 0.2 to 2000 J

- Automated weight recovery and speed reading system

- Wide range of easily modified supports, masses, fixtures, and accessories

- Zero maintenance and easy installation