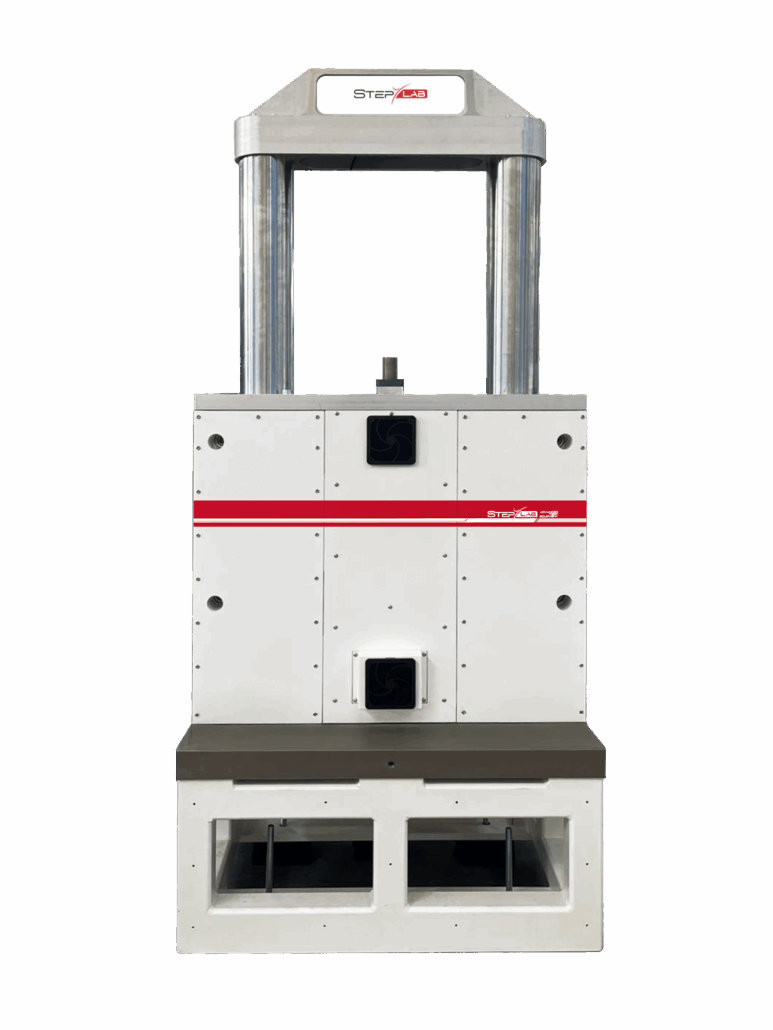

UHF – ULTRA-HIGH FREQUENCY TEST SYSTEM

For DMA/NVH applications

At STEP Lab, we have designed an advanced test system that reaches operating frequencies of up to 1000 Hz, thanks to its highly responsive electrodynamic actuation and extremely rigid design. Among the main applications of this machine are: dynamic characterisation of elastomers (DMA tests), evaluation of the vibroacoustic properties of motor mounts, bushings and shock absorbers (NVH tests), and high cycle fatigue tests (HCF).

Designed for research and development laboratories, the machine allows complex tests on materials and components with precise force and displacement control under a wide range of operating conditions.

Main features

- Test frequency up to 1000 Hz.

- Many applications: DMA, NVH, HCF, fracture mechanics, vibration analysis on components.

- High-performance electrodynamic actuation.

- Dedicated software: automated DMA test management, frequency analysis and reporting with Test Center.

- High-rigidity design: minimises vibrations and resonances. It also allows the installation of a variety of actuators, each capable of reaching different maximum loads and frequencies (250, 500, 1000 Hz).

- High precision sensors: load cells, accelerometers and integrated displacement transducers.

Applications

Using the DMA test system

The STEP Lab system for Dynamic Mechanical Analysis (DMA) allows the viscoelastic behaviour of elastomeric materials to be characterised by analysing how stiffness and energy dissipation vary with frequency, temperature and stress amplitude. Through frequency- or temperature-controlled sweeps, the machine measures the storage modulus (E’), loss modulus (E”) and damping factor (tan δ), providing essential information for compound development, material validation and dynamic performance optimisation. This analysis is crucial for predicting the behaviour of insulators, bushings and supports under real operating conditions.

Using the NVH test system

In the Noise, Vibration and Harshness (NVH) tests on shock absorbers, the system allows accurate analysis of the dynamic forces and vibrations generated during component operation, up to 1000 Hz. These tests allow us to assess how the shock absorber contributes to the transmission of vibrations and noise within the vehicle, particularly in high-frequency conditions associated with road irregularities or micro-bumps.

The machine makes it possible to measure vibrational transmissibility, system resonance, and the frequency dependence of the damping force, fundamental parameters for optimising acoustic comfort and NVH performance of the vehicle. The information obtained is essential for the design of quieter, more stable and comfortable suspensions, supporting the development of shock absorbers for cars, motorbikes and industrial vehicles.

Further applications

- High cycle fatigue (HCF) tests to assess the durability of materials and components subjected to repeated load cycles.

- Fracture mechanics studies to analyse the initiation and propagation of cracks in elastomers and mechanical components.

- Vibrational analysis of components, providing information on resonance, damping and dynamic response for precise engineering optimisation.

UHF – Ultra High Frequency Test System

| UHF Specs | UHF04 | UHF010 | UHF020 | UHF025 |

|---|---|---|---|---|

| Max. Peak force | 4.40 kN | 11.10 kN | 20.75 kN | 24.75 kN |

| Max. Dynamic force (Sinusoidal fatigue) | 2.25 kN | 5.55 kN | 10.65 kN | 15.85 kN |

| Max. Static force | 1.25 kN | 3.20 kN | 6.20 kN | 9.30 kN |

| Max. Test speed@Peak force | 5 m/s | 5 m/s | 2.7 m/s | 2.7 m/s |

| Max. Test frequency | 1000 Hz | 1000 Hz | 600 Hz | 600 Hz |

| Standard stroke | 115 mm | 115 mm | 160 mm | 160 mm |

| Cooling | Air | Air | Air | Air |

| Working temperature | 5-30 °C | 5-30 °C | 5-30 °C | 5-30 °C |

| Facility requirement | 3PH 400V | 3PH 400V | 3PH 400V | 3PH 400V |

One structure, multiple actuators

The high resonance structure used allows the installation of different types of actuators, each designed to reach different frequencies and maximum loads. The systems available are:

- UD series: up to 250 Hz with a maximum force of 30 kN, ideal for high force but lower frequency tests.

- XUD Series: operates up to 600 Hz with a force of 8.1 kN, balancing frequency and load.

- UHF series: reaches 1000 Hz with 5.5 kN, optimal for very high frequency tests but lower loads.

This modular configuration allows the system to be adapted to the specific requirements of the test, combining frequency and force flexibly without changing the basic structure.

Common standards

The machine can be configured to perform tests in accordance with the main international standards for elastomers and dynamic analysis, including:

- ISO 4664,ISO 37, and related standards for dynamic mechanical tests.

- ASTM D5992 and standards for DMA and NVH on polymeric materials.

- OEM specifications and automotive protocols on request.

Contact STEP Lab

Want to find out more about our DMA and NVH test system? Contact us for any requests, detailed technical specifications, and customised configurations.