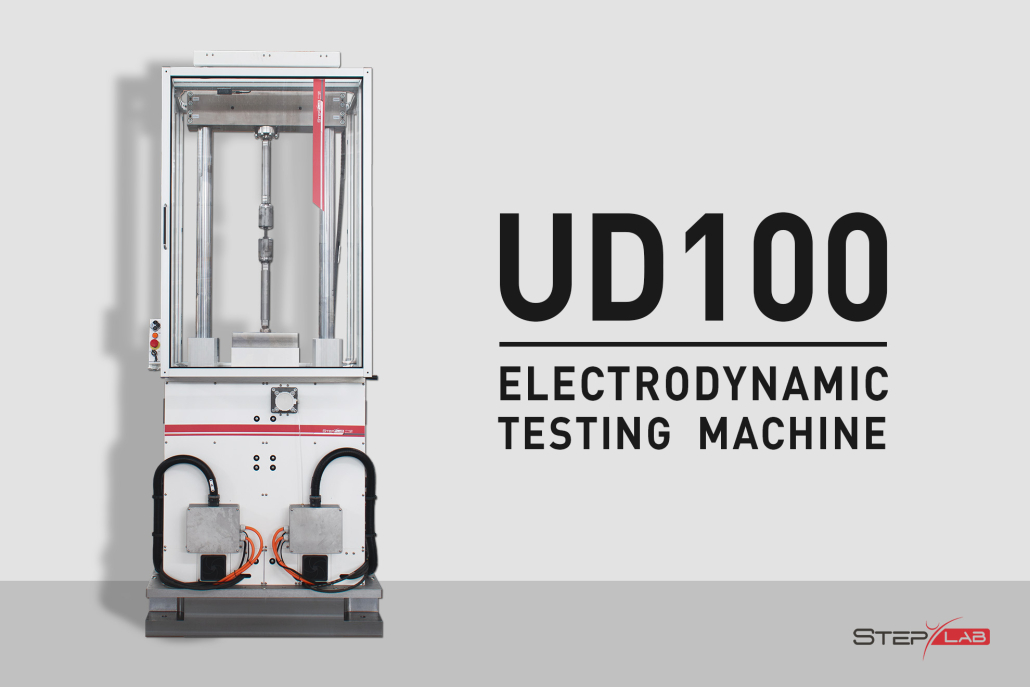

UD100: EMBRACE THE FUTURE OF MECHANICAL TESTING WITH STEP LAB

The world of testing has seen significant advances over the years, but the introduction of the new electrodynamic machine based on linear motors, UD100, marks a revolutionary leap in quality. Designed with a dynamic force of 100 kN, the UD100 is set to revolutionise the industry, being the first machine capable of replacing traditional hydraulic systems. Combining versatility, efficiency and seamless software integration, the UD100 offers a complete solution for a wide range of testing needs, including fatigue testing, static testing, high-speed tensile testing and biaxial testing. This article delves into the technical specifications and innovative features that make the UD100 the future of mechanical testing.

Technical Specifications and Features

High Dynamic Force

At the heart of the UD100 are its linear motors, which allow the machine to reach an impressive dynamic force capacity of 100 kN. With this high dynamic force, the UD100 can handle a wide variety of materials and testing scenarios. The flagship of the UD Series allows precise and accurate testing, ensuring that the results are reliable and consistent across different applications.

Max. Dynamic Force

Max. Static Force

Max. Test Speed

Max. Test Frequency

Standard Stroke

UD100 with Test Controller and cooling unit.

Easy Software Integration

The UD100 integrates seamlessly with the Test Center’s software ecosystem, providing a complete and cohesive solution for materials analysis. This integration allows for:

- Real-time Data Acquisition and Analysis: Collect and analyze data in real-time to make informed decisions quickly.

- Automated Test Procedures: Simplify complex testing procedures with automated processes, reducing the potential for human error.

- Comprehensive Reporting: Generate detailed reports that are easy to interpret and share with stakeholders.

By leveraging the power of the Test Center’s software, the UD100 enhances productivity and ensures that testing processes are efficient and effective.

Environmentally Friendly

In today’s environmentally conscious world, energy efficiency is a critical consideration. The UD100 requires 60 % less energy than outdated hydraulic machines. This high level of efficiency not only reduces operational costs but also minimizes the environmental impact of testing procedures. The UD100’s energy-efficient design makes it a sustainable choice for modern testing facilities.

Zero Maintenance Costs

Maintenance costs can be a significant burden for testing facilities, often leading to downtime and additional expenses. The UD100 addresses this issue with its zero-maintenance design. By eliminating the need for regular maintenance, the UD100 ensures continuous operation and reduces long-term costs. This feature alone can lead to substantial savings over the machine’s lifecycle.

Applications and Benefits

The UD100 is suitable for a wide range of applications across various industries, including:

- Automotive: Test the durability and strength of automotive components to ensure safety and reliability.

- Aerospace: Analyze materials used in aircraft construction to meet stringent industry standards.

- Construction: Evaluate the properties of building materials to ensure structural integrity.

- Manufacturing: Perform quality control tests on raw materials and finished products to maintain high standards.

The benefits of using the UD100 include:

- Enhanced Precision: High dynamic force and accurate data acquisition lead to precise testing results.

- Operational Efficiency: Versatility and software integration streamline testing processes, saving time and resources.

- Cost Savings: Energy efficiency and zero maintenance costs reduce operational expenses and increase profitability.

- Sustainability: Lower energy consumption and reduced maintenance contribute to a more sustainable testing environment.

Conclusion

The UD100 represents a significant advancement in the field of mechanical testing. Its combination of high dynamic force, versatility, seamless software integration, energy efficiency, and zero maintenance costs make it an unparalleled choice for modern testing facilities. As industries continue to demand more precise, efficient, and sustainable testing solutions, the UD100 stands out as the future of mechanical testing, ready to meet and exceed these evolving requirements.