What is an extensometer?

An extensometer is a precision instrument designed to measure how much a material deforms when subjected to tension or compression. These measurements are vital for understanding material behavior under stress and are fundamental in fields such as materials science, mechanical engineering, and quality control.

Whether you’re testing metals, composites, polymers, or delicate materials, extensometers help ensure your data is accurate and compliant with international testing standards like ISO and ASTM.

At STEP Lab, we offer a wide range of extensometers tailored to different materials and test setups. If you’re unsure which solution fits your application, please contact us.

Why use an extensometer?

When materials are pushed to their limits, engineers need tools that provide reliable data on how those materials respond. Extensometers deliver that precision by measuring strain—how much a material stretches or contracts—during testing.

This data is essential for calculating key mechanical properties like:

- Young’s modulus

- Tensile modulus

- Yield point

- Strain at break

- Poisson’s ratio

Accurate strain measurements support better material selection, product design, and safety evaluations.

Types of extensometers

Choosing the right extensometer depends on your sample type, testing environment, and precision needs. Extensometers typically fall into two broad categories: contact and non-contact.

Contact Extensometers

These devices, such as clip-on types or sensor arms, attach directly to the specimen. They are generally robust, affordable, and ideal for routine lab testing where throughput and ease of use are priorities.

- Clip-On Extensometers

Widely used for their simplicity and cost-effectiveness, these units provide accurate readings but may require careful handling, especially when working with fragile specimens.

Non-Contact Extensometers

For higher precision or delicate materials, non-contact options like laser or video extensometers are often the better choice. They capture deformation without physically touching the sample.

- Laser Extensometers

Using laser reflections, these systems offer high-resolution strain measurements—even in extreme temperatures or with challenging materials. - Video Extensometers

Leveraging digital imaging and advanced software, video extensometers track multiple points simultaneously. They’re ideal for measuring complex strain distributions or working with materials that fracture suddenly.

Key performance parameters

When selecting an extensometer, keep in mind the following criteria:

- Gauge length: The initial distance between measuring points. Standardized lengths ensure consistency across tests.

- Measuring range: Defines the maximum deformation the extensometer can track—critical when working with materials that undergo large strains.

- Temperature tolerance: Some tests occur under extreme conditions. Make sure your extensometer can operate within the required temperature range.

Each of these parameters affects the accuracy and reliability of your test results. Calibration and routine verification are also essential to maintain performance over time.

Integration and Calibration

Modern extensometers, especially non-contact types, can easily integrate with universal testing machines via analog or digital outputs (e.g., ±10V or RS-232). This connectivity ensures seamless data acquisition and control.

Regular calibration against certified standards ensures traceability and compliance. At STEP Lab, our extensometers can be calibrated down to deviations of just 1 μm, supporting the highest demands in materials testing.

Real-world applications

Extensometers are used across industries to test a wide variety of materials:

- Metals and alloys

- Plastics and elastomers

- Composites

- Textiles, ropes, and films

- Paper and wood

From aerospace to automotive to consumer goods, extensometers support product safety, performance, and innovation.

Conclusion

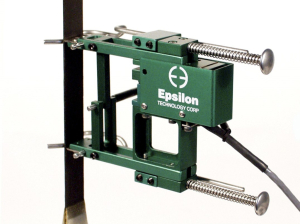

Extensometers are essential tools for accurately measuring material deformation under various loading conditions. Whether you’re conducting tensile, compression, or fatigue tests, choosing the right extensometer ensures reliable results and better insights into material performance. As an authorized distributor of Epsilon extensometers, STEP Lab provides high-quality solutions backed by expert support.

Contact us to learn more or to request a recommendation tailored to your application.

FAQ

What types of extensometers are available?

There are contact extensometers (mechanical or clip-on), non-contact optical extensometers (such as laser or video), and high-temperature or fatigue-rated models designed for specific test environments.

How do I choose the right extensometer for my test?

The right choice depends on your test type, material properties, gauge length, and environment. Our team at STEP Lab can help you evaluate your requirements and suggest the most suitable Epsilon model.

Can extensometers be used for both tensile and compression tests?

Yes, many extensometers are designed for both tension and compression. However, it’s important to select one that meets the accuracy and travel range required by your specific application.

Do you offer technical support and calibration services?

Absolutely. As a certified Epsilon reseller, STEP Lab provides full technical support, calibration guidance, and after-sales assistance to ensure your system performs reliably over time.

Are Epsilon extensometers compatible with all testing machines?

Most Epsilon extensometers are compatible with a wide range of testing systems. We can verify compatibility or provide adapters as needed.