Introducing ASTM D3574: Recognized globally as the benchmark for evaluating Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. Here at STEP Lab, we’re dedicated to providing cutting-edge solutions that adhere to this standard, ensuring top-quality testing machines and accessories.

ASTM D3574: WHAT IS?

ASTM D3574 is an ASTM Standard that refers to test methods apply to slab, bonded, and molded flexible cellular products known as urethane foams. Urethane foam typically refers to an expanded cellular material created through the reaction of active hydrogen compounds, water, and isocyanates.

ASTM D3574: USE

These foams are predominantly utilized in the furniture, bedding, and automotive industries to fabricate seats and mattresses that enhance consumer ergonomics and provide superior comfort. ASTM D3574 testing serves as an effective method for comparing different foam samples, which often vary in chemical composition, density, and porosity. This standard is frequently paired with advanced pressure analysis techniques to replicate the load experienced by the human body accurately.

ASTM D3574: WHAT DOES IT MEASURE?

ASTM D3574 aims to assess the compressive, tensile, and tear-resistant characteristics of foam. Among these, compressive tests are frequently conducted as they hold significant importance in determining product performance.

ASTM D3574: DIFFERENT TESTS

ASTM D3574 encompasses a range of 18 mechanical tests. While not all of these tests necessitate the use of a universal testing machine, the following ones do:

- Test B1 – Indentation Force Deflection Test (IFD) *Most Common

- Test B2 – Indentation Residual Gauge Length Test (IRGL)

- Test C – Compression Force Deflection Test *Most Common

- Test D – Constant Deflection Compression Set Test

- Test E – Tensile Test

- Test F – Tear Resistance Test

ASTM D3574: DYNAMIC TESTING

While static tests offer valuable insights into the initial properties and constraints of foam, long-term dynamic testing is essential for manufacturers to gauge product durability. End-users anticipate foam products to maintain their supportive characteristics not only upon initial use but also after repeated usage over time. The following tests can be conducted on STEP Lab electrodynamic systems utilizing linear motors:

- Test I2 – Dynamic Fatigue Test, Roller Shear

- Test I3 – Dynamic Fatigue Test, Constant Force Pounding

- Test I4 – Dynamic Fatigue Test, Carpet Cushion

- Test I5 – Dynamic Fatigue Test, Constant Deflection Pounding

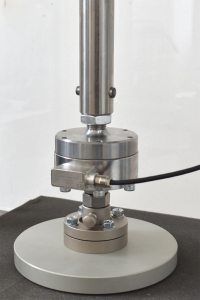

TESTING MACHINES FOR ASTM D3574

Our EA dynamic and fatigue testing machine is a versatile solution for conducting tests that comply with ASTM D3574.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test