Testing the durability of materials under real-world conditions is essential for ensuring their long-term performance. In industries like pipeline manufacturing, where polyethylene (PE) materials are widely used, evaluating resistance to slow crack growth (SCG) is crucial. Advanced testing methods provide accurate predictions of material performance, ensuring reliability and safety in critical applications.

At STEP Lab, we are committed to manufacturing testing systems that guarantee adherence to industry standards, such as ISO 18489.

WHAT IS ISO 18489?

ISO 18489 is a standard developed to assess the resistance of polyethylene (PE) materials to slow crack growth (SCG) under cyclic loading. The test simulates long-term stress and crack initiation in materials like PE pipes and fittings by applying cyclic tensile loads to notched specimens. This process accelerates the testing, providing reliable results within a shorter time frame. ISO 18489 is particularly important for long-term applications, such as gas and water pipelines, as it records the number of loading cycles a material can endure before failure. This helps manufacturers evaluate the material’s strength and durability for critical infrastructure.

WHY IS ISO 18489 IMPORTANT?

The importance of ISO 18489 lies in its ability to provide accurate, accelerated testing of PE materials. This standard ensures that manufacturers can quickly and effectively evaluate the durability of materials, leading to better material selection for critical infrastructure projects. By reducing the time needed for testing while maintaining accuracy, ISO 18489 supports the development of more resilient and reliable materials.

ISO 18489 TESTING METHOD

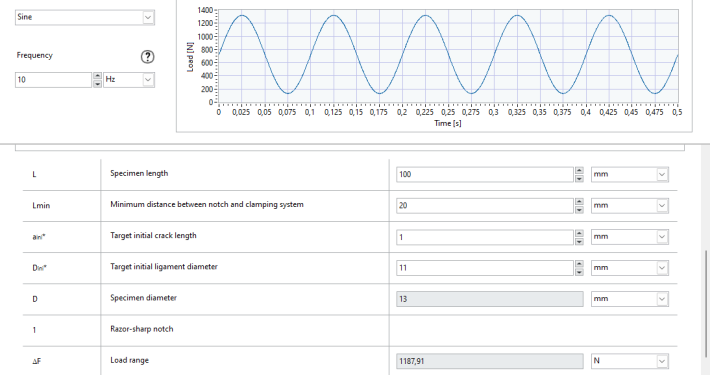

The test process under ISO 18489 involves subjecting a cylindrical specimen with a circumferential notch to cyclic tensile loading. Key steps in the testing process include:

- Preparing the cylindrical specimen with a sharp notch.

- Applying cyclic loading with constant force amplitude.

- Monitoring and recording the number of cycles until the specimen fails. The test provides an accelerated evaluation of the material’s resistance to slow crack growth, allowing for results to be obtained at ambient temperatures without altering the polymer structure.

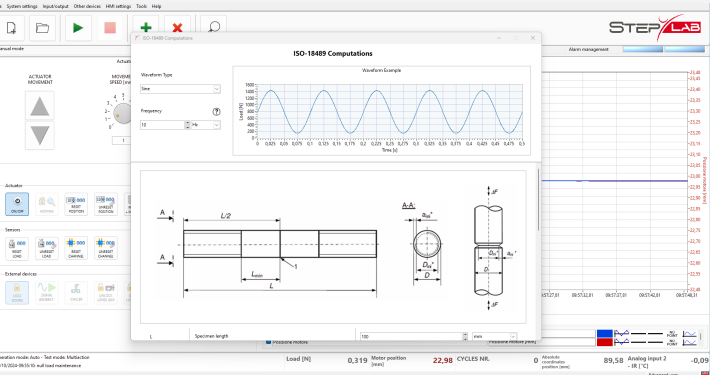

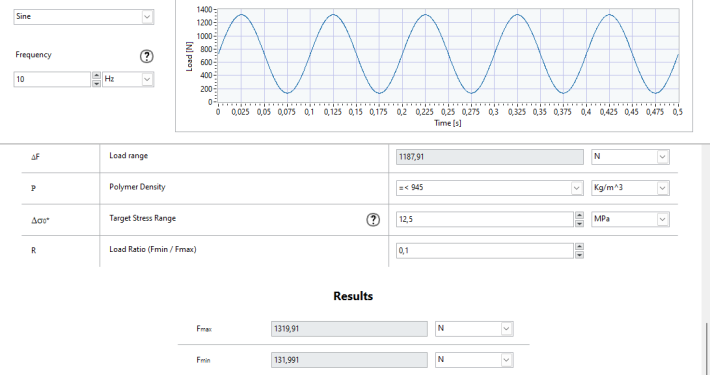

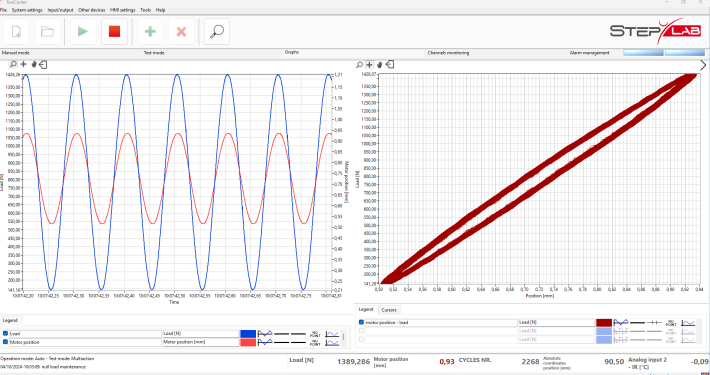

The test process requires a loading system capable of applying and recording a cyclic load with precisely defined limits using a sinusoidal waveform. The cyclic load, characterized by the maximum load (Fmax) and the load ratio (R), must maintain constant maximum and minimum loading values with an accuracy of ±1% throughout the test.

The load-cycle frequency must not exceed 10 Hz, with an accuracy of ±1%. Hysteretic heating at this frequency typically has no significant effect on the failure cycle number (Nf); however, if extraordinary heating at the crack tip is suspected, the frequency should be reduced to 5 Hz or 1 Hz, maintaining the same accuracy.

TESTING MACHINE FOR ISO 18489

To perform a test compliant with ISO 18489, both the EA and UD testing machines are suitable options. For frequency ranges up to 20 Hz, the EA Series is recommended, as it delivers reliable performance and is a more budget-friendly solution. However, if your testing requirements are more demanding, the UD Series is the ideal choice. These electrodynamic machines provide greater power and versatility, making them perfect for advanced and diverse applications.

- High dynamic loads: 100 kN for UD, and 200 kN for EA.

- Accurate cyclic loading: Ensuring consistent force application.

- Force-controlled pneumatic grips: Preventing overloading during clamping.

- Wide range of add-ons: Possible integration of Epsilon extensometers and/or environmental chambers.

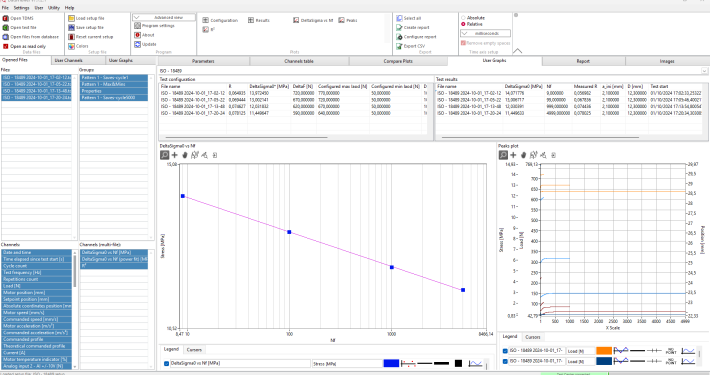

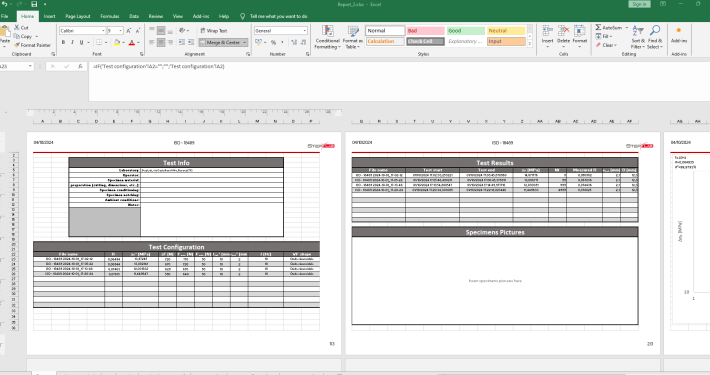

In addition, our engineers have developed dedicated software for exporting and analysing test results. The entire ISO 18489 test sequence is handled efficiently, producing clear and exportable outputs.

For more information on our test systems, click the button below.

FAQ

What materials can be tested using ISO 18489?

This standard is designed for testing polyethylene materials, particularly PE pipes and fittings, to evaluate their resistance to slow crack growth.

Can the test be performed at different temperatures?

Yes, although the test is typically conducted at room temperature (23°C), it can be performed at other temperatures by using a temperature-controlled chamber to ensure consistent results.

Why is cyclic loading used instead of static loading?

Cyclic loading better simulates the stresses that materials face during their operational lifespan, providing a more accurate measure of long-term durability compared to static loading, which can cause premature creep and failure.

What kind of results does ISO 18489 provide?

The test records the number of loading cycles a material can withstand before failure occurs. This helps manufacturers determine the material’s resistance to slow crack growth and its suitability for long-term use in critical applications.