What is ASTM D790?

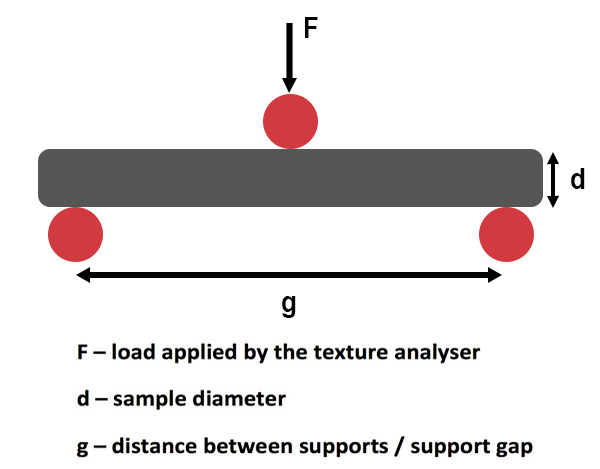

ASTM D790 is the “Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials.” Unlike a tensile test which pulls a material apart, ASTM D790 utilizes three-point loading system applying a bending force to the center of a specimen supported at two points.

This method is specifically designed for rigid and semi-rigid materials that do not fail (break) within a 5% strain limit.

While it is often compared to ISO 178, ASTM D790 is the primary reference for the North American market and differs slightly in specimen dimensions, support span requirements, and test speeds.

What does ASTM D790 measure?

The test generates a load-deflection curve, which is used to calculate several critical mechanical values:

- Flexural modulus: A measure of the material’s stiffness or its ability to resist bending. ASTM D790 offers three ways to calculate this: Tangent modulus (the initial slope of the stress-strain curve), Secant modulus (the ratio of stress to strain at a specific point), and Chord modulus (the slope between two predefined points).

- Flexural strength: The maximum stress the material can withstand during bending before failure or reaching 5% strain.

- Flexural stress at break: The stress at which the specimen ruptures.

- Strain at yield: The amount of deformation occurring at the point where the material begins to deform plastically.

Why is ASTM D790 important?

Flexural properties are vital for engineers and designers because many plastic components (such as brackets, housings, and structural panels) are subjected to bending loads rather than pure tension during their service life.

Material Comparison: It allows for the direct comparison of different polymer blends or reinforcement levels.

Quality Control: Manufacturers use it to ensure consistency between production lots.

Design Validation: It provides the data needed to ensure a part will not sag or break under its intended weight.

ASTM D790: Test methods

| Procedure | Strain Rate | Primary Application | Key Characteristics |

|---|---|---|---|

| Procedure A | 0.01 min⁻¹ | Standard & Brittle Materials | The default method for most plastics. Ideal for measuring the modulus of elasticity and flexural strength. |

| Procedure B | 0.1 min⁻¹ | Ductile & High-Deflection Materials | Designed for materials that do not break early. Higher speed is used to reach the 5% strain limit or failure point more efficiently. |

ASTM D790: Key technical requirements

Specimen Dimensions: For standard molding compounds, the typical specimen is 3.2 mm x 12.7 mm x 127 mm.

Span-to-Depth Ratio: The distance between the supports (span) is typically set at 16 times the thickness of the specimen (16:1 ratio).

Deflection Measurement: While crosshead travel can be used, a deflectometer is recommended for high-accuracy modulus measurements to eliminate “compliance” (the tiny deflections of the machine itself).

The 5% Limit: The standard is generally only valid up to 5% outer fiber strain. If a material hasn’t broken by this point, the test is typically stopped, as the mathematical formulas for stress become less accurate beyond this level.

ASTM D790: System configurations

ASTM D790 testing is conducted using an EA Series testing machine, available in both tabletop and floor models, customized with specific accessories to meet laboratory requirements.

A typical configuration consists of an EA Series machine equipped with a 3-point bend fixture. Depending on how strain is recorded, the setup is classified into two categories: Type 1 and type 2.

- Type 1: Crosshead displacement

In this configuration, strain is calculated based on the movement of the machine’s crosshead. This is the standard “basic” setup and does not require additional sensors. - Type 2: Extensometer integration

For higher accuracy or specific compliance needs, the test machine can be integrated with an extensometer (non-contacting or clip-on).

Testing machines for ASTM D790

STEP Lab provides high-performance electromechanical testing machines (EA Series) optimized for ASTM D790. Our systems ensure precise load application and data acquisition, meeting the highest industry standards.

For more information about ASTM D790 testing solutions, contact us today!