In industries where adhesive performance is critical, standards like ASTM D3330 provide essential guidance on evaluating the peel adhesion of pressure-sensitive tape. At STEP Lab, we provide high-quality testing solutions tailored for ASTM D3330. Our equipment offers the precision and flexibility needed to meet varying adhesive testing requirements, with unique enhancements that distinguish us from competitors.

What is ASTM D3330?

ASTM D3330 is a widely recognized standard used to measure the adhesive strength of pressure-sensitive tapes. It offers a set of testing methods designed to evaluate how well a tape resists peeling under controlled conditions. By providing objective metrics, ASTM D3330 enables manufacturers to validate product consistency and allows buyers to make informed comparisons between different tapes. This standard is essential across multiple industries—particularly where reliable adhesion is crucial for packaging, automotive, and other applications.

Specimens and Test Preparations

To achieve accurate and repeatable results, ASTM D3330 specifies dimensions for test specimens. Typically, specimens are cut to a width of 24 mm (±0.5 mm tolerance) and length of 300 mm. These dimensions allow for consistent measurements across different tests. When working with tapes wider than 24 mm, specimens should be taken from the center of a strip removed from the roll.

Our machines are designed to ensure consistent tension and pressure application during specimen setup, providing enhanced reliability in results. Additionally, our equipment can be customized to accommodate various widths and lengths based on specific client needs.

ASTM D3330 Test Methods

ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview:

- Method A – Measures 180° peel adhesion of single-coated tape.

- Method B – Assesses backing adhesion of single-coated tape.

- Method C – Tests the peel strength of double-coated tape.

- Method D – Evaluates liner adhesion for single- or double-coated tapes.

- Method E – Analyzes adhesion in adhesive transfer tapes.

- Method F – Measures 90° peel adhesion of single-coated tape.

Each method involves applying the tape to a standard test panel and peeling it at a specified angle, which simulates real-world stresses. The methods provide a detailed understanding of an adhesive’s behavior under different forces and configurations.

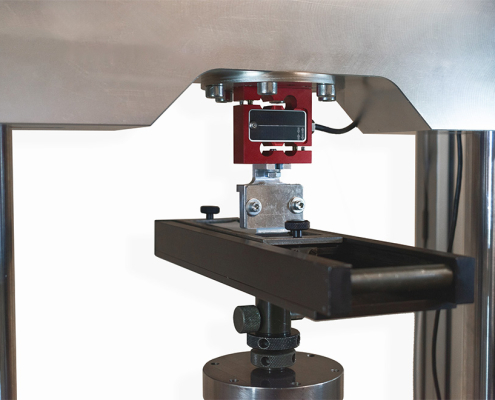

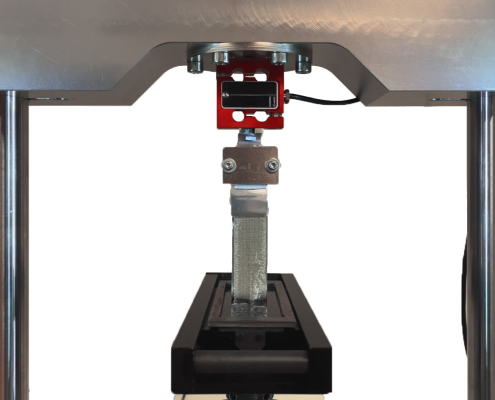

At STEP Lab, we offer 90° and 180° peel test kits seamlessly integrate with both EA and UD series machines, delivering accurate force measurement at each peel angle. With STEP Lab, the transition between test methods is simplified, making it easy to switch from a 90° to a 180° peel setup in minimal time.

Results and Data Analysis

The results of ASTM D3330 tests are calculated from the average force required to peel the tape. Data is recorded at least once per 1.0 mm of tape peeled, with the first 25 mm omitted from the results to ensure accuracy. To determine the peel adhesion value, the average force measured over the next 50 mm of tape is divided by the specimen width.

The test report should include:

- Peel adhesion value

- Test method used

- Dwell time

- Specimen width

- Test conditions (temperature and humidity)

With STEP Lab’s advanced data logging features, users can efficiently track every parameter, including temperature and humidity. Our machines allow seamless integration with digital interfaces, making it easy to store and analyze data over time for comprehensive quality assurance.

TESTING MACHINES FOR ASTM D3330

STEP Lab’s EA and UD series dynamic and fatigue testing machines provide unmatched precision, reliability, and ease of use for ASTM D3330 tests. With features that support flexibility in specimen preparation, data collection, and method switching, our tools are designed to meet the exacting needs of adhesive tape testing.

Explore STEP Lab’s customized ASTM D3330 solutions to ensure your tapes meet the highest standards of peel adhesion reliability.