At STEP Lab, we specialize in developing advanced testing equipment designed to conduct compression tests on plastics. Our unwavering commitment to precision and quality ensures that your testing demands are consistently met with superior performance and reliability. Our products adhere to international standards, including the rigorous specifications outlined in ASTM D695.

WHAT IS ASTM D695?

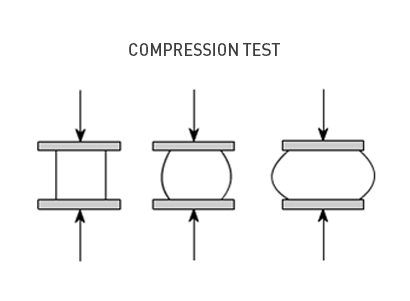

ASTM D695 is a standardized test method employed to determine the mechanical properties of both unreinforced and reinforced rigid plastics, including high-modulus composites. The test specifically evaluates the behavior of materials when subjected to compression at relatively low uniform rates of straining or loading.

WHAT DOES ASTM D695 MEASURE?

ASTM D695 provides a systematic approach to assess various compressive properties of rigid plastics, including modulus of elasticity, yield stress, deformation beyond the yield point, and compressive strength. This method offers a reliable means of understanding how materials perform under compressive forces, crucial for industries ranging from construction to automotive manufacturing.

WHY IS ASTM D695 IMPORTANT?

- Quality Control: ASTM D695 aids in quality control by providing standardized procedures for evaluating material properties.

- Performance Prediction: The test results enable engineers to predict how materials will perform under compressive loads, facilitating informed decision-making in material selection for specific applications.

- Safety Assurance: Understanding a material’s compressive properties is crucial for ensuring structural integrity and safety in various applications, from building construction to aerospace engineering.

ASTM D695 – TEST SPECIMENS

Specimens can be machined from various forms such as sheets, plates, rods, or tubes. Careful attention to machining is essential to maintain smooth surfaces and precise dimensions, ensuring accurate test results.

ASTM D695 – TEST METHODS

- Preparation of Test Specimens: Specimens can be prepared by machining operations or through compression or injection molding, ensuring smooth surfaces and precise dimensions.

- Number of Test Specimens: The standard mandates testing a minimum of five specimens for isotropic materials and ten for anisotropic materials, ensuring comprehensive evaluation.

- Procedure:

- Measure specimen dimensions accurately.

- Align the specimen properly within the compression tool.

- Conduct the test at a specified speed (1.3 mm/min) while recording load and strain data.

- Adjust testing parameters based on desired output (compressive strength only or stress-strain data).

ASTM D695 – TESTING MACHINES

The test requires a compression testing machine capable of exerting controlled forces on the specimen, such as our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test