Fatigue tests are used to determine the effect of various factors on the fatigue resistance of plastic materials subjected to uniaxial stress. The results of these tests can be used to guide the selection of plastic materials for conditions of repeated flexural stress.

WHAT IS ASTM D7791?

The ASTM D7791 standard is a test method used to measure the mechanical properties of plastic materials subjected to uniaxial loading. The standard applies to rigid and semi-rigid plastic materials and is used to determine their tensile and compressive properties. Stress and strain levels are below the proportional limit of the material, where the strains and stresses are relatively elastic.

WHAT ARE THE TWO PROCEDURES?

The test is carried out using two procedures:

- Procedure A, which tests the fatigue resistance in tension: a specimen of rectangular or circular cross section is gripped by the ends of the specimen, pulledequally in oppipped by the ends of the specimen, pulledequally in opposite directions, and released back to its originalposition or load. The specimen is cyclically loaded in tensionto a specific stress or strain level at a uniform frequency untilthe specimen ruptures or yields. From these tests, fatiguestrengths can be determined at specified numbers of cycles. Atleast, four different stress or strain levels are tested to constructa stress versus number of cycles to failure (S-N) curve or astrain versus number of cycles to failure (r-N) to determine theuniaxial endurance limit of the material in tension.

- Procedure B, which tests the fatigue resistance in compression, but only for rigid plastic materials: a specimen of rectangular or circularcross section is compressed equally from opposite directionsand released back to its original position or load. The specimenis cyclically loaded in compression to a specific stress or strainlevel at a uniform frequency until the specimen ruptures oryields. From these tests, fatigue strengths can be determined atspecified numbers of cycles. At least, four different stress orstrain levels are tested to construct a stress versus number ofcycles to failure (S-N) curve or a strain versus number ofcycles to failure (r-N) to determine the uniaxial endurance limitof the material in compression.

Comparative tests can be conducted in accordance with either procedure, provided that the procedure is found satisfactory for the material being tested.

WHY IS ASTM D7791 IMPORTANT?

The ASTM D7791 standard is important because it provides a standardized methodology for evaluating the mechanical properties of plastic materials. This is essential to ensure the quality and reliability of products using such materials, as well as to ensure consumer safety. Additionally, the standard provides a common basis for communication between manufacturers, suppliers, and purchasers of plastic materials, contributing to greater consistency and reliability of test results.

The results of these tests are suitable for design only if the test conditions realistically simulate service conditions or if a methodology for accounting for service conditions is available and clearly defined. The procedure accommodates various specimen preparation techniques, but results obtained from different methods should not be considered comparable unless equivalency is demonstrated.

ADDITIONAL INFORMATION ABOUT ASTM D7791

- The standard also stipulates that values must be expressed in SI units, and values in parentheses are for informational purposes only.

- Additionally, the standard does not purport to address all safety concerns associated with its use, and it is the responsibility of the user to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

- It is important to note that there is no known ISO equivalent to this standard.

WHAT ARE THE REQUIREMENTS FOR THE TEST?

Regarding the test procedure, the standard requires the use of a uniaxial loading system with tension and compression capabilities, which is used to apply the load to the test material. The test involves applying a cyclic load at a specific frequency until the material breaks or reaches a specified breaking point.

The properties of the plastic material can vary with specimen depth and test frequency. A frequency of 5 Hz or less is recommended for testing. The material response in fatigue is not the same for all plastics. If a plastic does not have an elastic region, plastic deformation can occur during testing, causing caution to be taken when using the results for design.

TESTING MACHINES FOR ASTM D7791

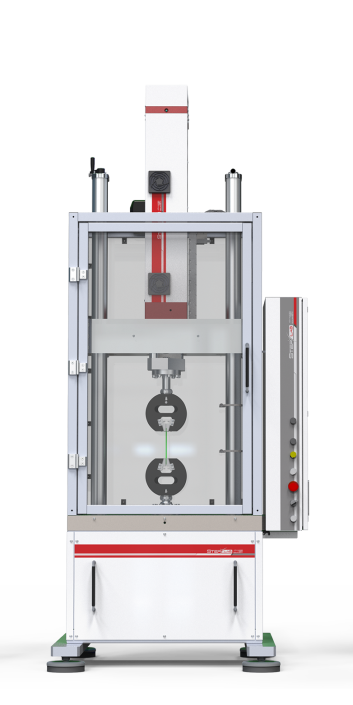

Our EA dynamic and fatigue testing machine is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test