Experience excellence at STEP Lab, where we engineer testing machines that redefine industry standards. Our commitment to precision and innovation ensures superior performance and reliability, meeting and exceeding your testing needs. Compliant with international standards like ASTM E399, our solutions guarantee top-tier quality and efficiency.

WHAT IS ASTM E399?

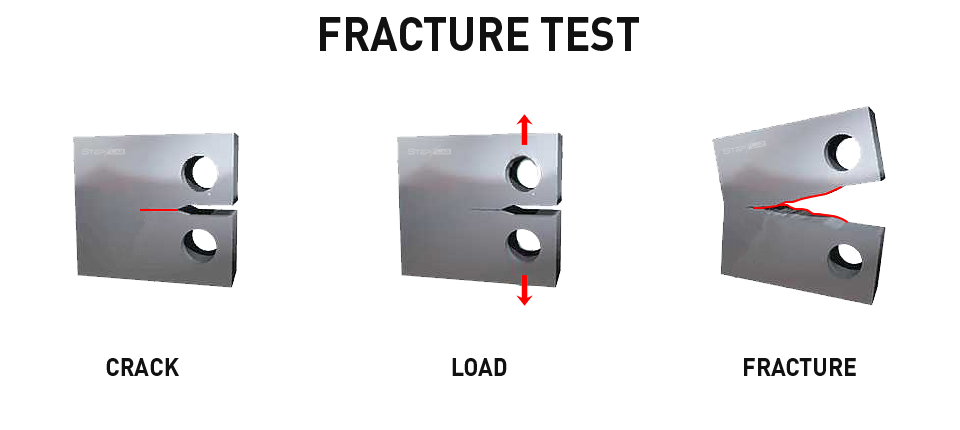

ASTM E399 delineates the methodology for determining fracture toughness (KIc and optionally KIsi) of metallic materials under predominantly linear-elastic, plane-strain conditions. It entails the utilization of fatigue precracked specimens with a thickness of 1.6 mm (0.063 in.) or greater, subjected to gradually increasing crack-displacement force.

WHAT DOES ASTM E399 MEASURE?

ASTM E399 measures fracture toughness, specifically denoted as KIc. Fracture toughness characterizes a material’s resistance to fracture under linear-elastic stress and severe tensile constraint conditions. It reflects the material’s behavior in the presence of a sharp crack, approaching tritensile plane strain near the crack front while maintaining a small plastic zone compared to the crack size, specimen thickness, and ligament ahead of the crack.

WHY IS ASTM E399 IMPORTANT?

The determination of fracture toughness is crucial for assessing the structural integrity and reliability of metallic materials, especially in critical applications where fracture resistance is paramount. ASTM E399 provides standardized procedures for obtaining fracture toughness values, enabling manufacturers, engineers, and researchers to make informed decisions regarding material selection, design optimization, and failure analysis.

ASTM E399 – TWO MAIN PARTS

The ASTM E399 standard comprises two main parts.

- The first part outlines general recommendations and requirements for fracture toughness testing, including specific guidelines for the KIc test procedure. It covers essential aspects such as specimen preparation, loading configurations, and data analysis methods necessary for conducting accurate and reliable tests.

- The second part consists of detailed recommendations for displacement gauge and loading fixture design, special requirements for individual specimen configurations, and comprehensive procedures for fatigue precracking.

Together, these two parts provide a comprehensive framework for conducting fracture toughness tests according to ASTM E399 standards.

HOW TO CONDUCT AN ASTM E399 TEST?

The ASTM E399 test procedure involves the following steps:

- Begin by preparing the sample according to the guidelines outlined in the standard.

- Measure the width and thickness of the notched sample and document the measurements for reference.

- Load the prepared sample into the designated fixture, ensuring proper alignment.

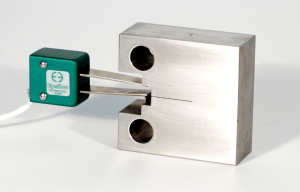

- Attach the displacement gauge to the crack opening of the specimen to accurately measure crack mouth opening displacement (CMOD).

- Apply the load to the specimen in accordance with the prescribed specifications detailed in the standard.

- Conduct the test, incrementally increasing the load until the applied force reaches the maximum force that the sample can withstand.

- Throughout the testing process, record the maximum force applied on the sample for data analysis and reporting purposes.

TESTING MACHINES FOR ASTM E399

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test