In the biomedical field, international testing standards play a critical role in validating the safety, effectiveness, and long-term performance of medical devices. These standards provide a common framework for evaluating implants, instruments, and materials under conditions that closely mimic the human body.

One of these standards is ASTM F2582.

What does ASTM F2582 measure?

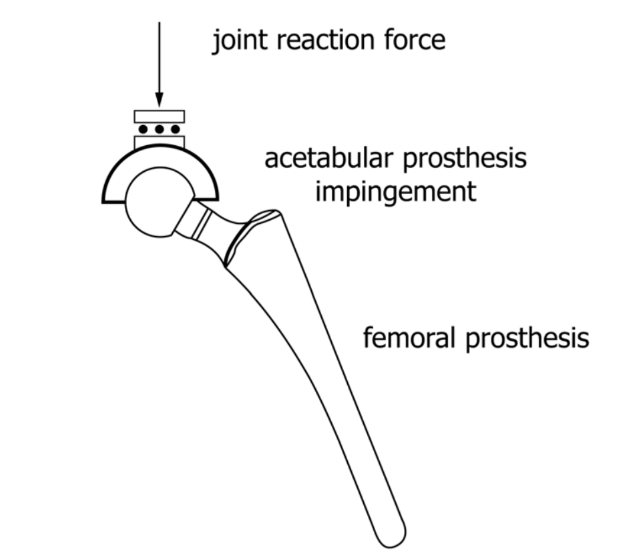

ASTM F2582 measures the axial displacement impedance of an acetabular construct. This refers to the implant’s resistance to vertical motion when subjected to:

- Static loads: Representing weight-bearing at rest (e.g., standing still);

- Dynamic loads: Simulating activities such as walking or stair climbing.

More specifically, it quantifies:

- The initial displacement under a small preload;

- The change in displacement over time during cyclic loading;

- The stiffness or resistance of the construct to axial forces;

- These metrics help assess how securely the acetabular cup is fixed in the bone, which is critical to long-term performance.

Why is ASTM F2582 important?

Stability of the acetabular cup is essential for the success of a hip replacement. Excessive micromotion or poor fixation can lead to complications such as:

- Implant loosening;

- Pain or discomfort;

- Revision surgery.

By providing a standardized method to test axial stability, ASTM F2582 allows:

- Manufacturers to compare different implant designs or fixation techniques;

- Researchers to evaluate the effects of materials, surface coatings, or bone densities;

- Regulatory bodies to assess mechanical performance claims.

In essence, this test helps ensure that implants are both safe and effective for long-term clinical use.

How is an ASTM F2582 test performed?

The test involves embedding the acetabular implant into a bone analog material (often polyurethane foam or synthetic bone) and then applying axial loads through a testing machine.

The key steps are:

-

- Specimen preparation:

- The acetabular cup is implanted into a prepared cavity of the test block;

- Bone cement may or may not be used, depending on the implant type.

- Mounting:

- The specimen is mounted in a testing frame with the acetabular cup facing upward.

- Static testing:

- A small preload is applied to ensure contact;

- A specified axial force is applied, and displacement is recorded.

- Dynamic testing:

- Cyclic loading (typically sinusoidal) is applied to simulate real-life movement;

- The number of cycles and loading profile are defined in the test protocol;

- Displacement is monitored over time to assess micromotion or changes in stiffness.

- Data analysis:

- Results are reported as displacement vs. load curves;

- Axial stiffness and displacement impedance are calculated.

- Specimen preparation:

TESTING MACHINES FOR ASTM F2582

STEP Lab provides high-performance electromechanical testing machines (EA Series) tailored for ASTM F2582. Our systems ensure precise load application and data acquisition, meeting the highest industry standards.

For more information about ASTM F2582 testing solutions, contact us today!