The complete guide to shock absorber testing machines: Technologies, performance, applications

Shock absorber testing machines, also known as shock dynos, are essential for characterizing, validating, and verifying the performance of shock absorbers and suspension components.

At STEP Lab, we design testing systems that replace traditional hydraulic solutions with cleaner, safer, and more precise electric technologies.

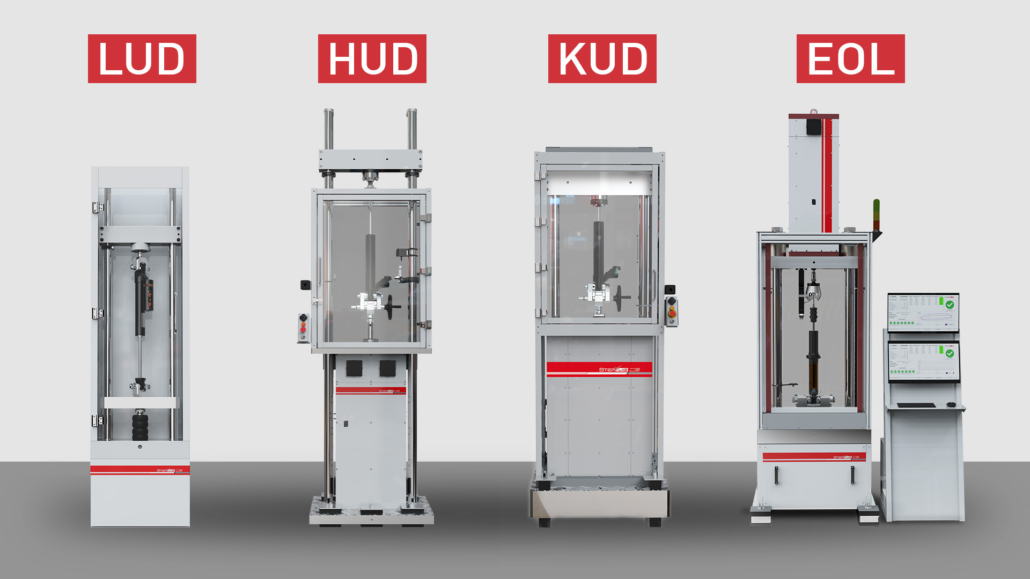

This guide explains the differences between our four main product families (LUD, HUD, KUD and EOL) and helps you understand which shock absorber testing machine best fits your needs.

What is the LUD Series?

An electromechanical shock absorber testing machine with top performance

LUD is an electromechanical test bench designed to be the right compromise between advanced and high-performance testing machines and basic and outdated dynos for shock absorber testing.

Main capabilities:

- 20/28 HP electric motor

- Peak load up to 20 kN

- Variable stroke up to 350 mm (14 in)

- Road profiles replication

- Fully software-controlled stroke and speed

Best for: Small/medium workshop, Rapid quality control on shock absorbers, Racing teams conducting on-site or mobile testing, R&D departments, Damper manufacturers, and Motorcycle/car workshops that want to perform rapid diagnostics.

What is the HUD Series?

The industry standard electrodynamic shock dyno

HUD Series is our most widely adopted shock absorber test bench, used for high-dynamic tests. HUD is commonly used for characterization tests, and durability tests.

Key features:

- Characterization up to 8 m/s (300 in/s)

- Load capacity up to 66 kN (15 kip)

- Durability tests

- Road profile reproduction

- Spring testing

- HiL integration

Best for: Shock absorber or suspension manufacturers, R&D centers, Engineering teams working on high-performance projects (e.g. sports, off-road, heavy duty), Companies that perform large-scale durability testing, and Specialised workshops offering advanced testing services to external customers.

What is the KUD Series?

A high-force durability shock absorber tester with no hydraulics

KUD Series is built for long, continuous durability testing and high-force characterization. KUD is fully electric, with no pumps or hydraulic oil.

Performance highlights:

- Durability tests up to 6 m/s (240 in/s) and 82 kN (18 kip)

- Characterization tests up to 8 m/s (300 in/s) and 120 kN (27 kip)

- Accurate road profile simulation

- Hardware-in-the-Loop (HiL) integration

Best for: R&D and durability departments that must perform millions of high-load cycles on shocks and struts to validate new designs

What is the EOL Series?

A reliable end-of-line shock absorber testing machine for production

EOL systems is designed for high-throughput End-Of-Line testing of components like shock absorbers. It ensures that every unit produced meets performance specifications before delivery.

Advantages:

- Based on HUD linear motor-based actuators or electromechanical technology (EA)

- Standard or fully customized solutions

- Compatible with ERP, MES, and automation systems

- Designed for 24/7 production environments

Best for: High-volume production lines that require rapid, automated, barcode-tracked quality checks on every single damper before shipping.

Comparison table

| LUD SERIES | HUD SERIES | KUD SERIES | EOL SERIES | |

|---|---|---|---|---|

| Type of test | Performance Reliability | Performance Quality | Durability Reliability | End of Line Quality |

| Max. Speed | 1.5 m/s | 8.0 m/s | 6.0 m/s | 6.5 m/s |

| Max. Acceleration | 6 G | 75 G | 50 G | 65 G |

| Peak force | 20 kN | 66 kN | 160 kN | 66 kN |

| Dynamic force | 7 kN | 24 kN | 82 kN | 24 kN |

| Static force | 6 kN | 18 kN | 58 kN | 18 kN |

STEP Lab vs Competitors

STEP Lab

- Higher stiffness and structural rigidity for more precise force control

- Wider dynamic range with stable performance at low and high velocities

- Lower friction thanks to optimized linear guides and motor architecture

- Advanced control electronics enabling tighter loop control and smoother waveforms

- Easier HiL/automation integration with modular software and open interfaces

- Reduced maintenance due to robust components and optimized cooling design

Competitors

- Lower frame rigidity leading to force distortion at higher loads

- Limited bandwidth, reduced accuracy at high speeds

- Higher internal friction affecting low-speed repeatability

- Basic controllers with fewer tuning options and slower response

- Restricted integration capabilities

- More frequent maintenance due to mechanical wear and less efficient thermal handling

Conclusion

The LUD, KUD, HUD, and EOL Series cover every testing need, from R&D characterization to high-force durability and end-of-line production.

With fully electric architectures, STEP Lab’s systems offer cleaner operation, higher accuracy, and lower lifecycle cost compared to hydraulic alternatives.

If you’re looking for a shock absorber testing machine, a shock dyno, STEP Lab provides one of the most advanced solutions on the market.

FAQ

What is a shock dyno?

A shock dyno is a testing machine that measures the force-velocity behavior of a shock absorber or damper.

What is the difference between HUD and KUD?

HUD is for high-dynamics characterization; KUD is for high-force durability testing without hydraulics.

Can electric shock dynos replace hydraulic systems?

Yes. Electromechanical and electrodynamic systems deliver comparable or superior speed and force with lower maintenance and no oil.

Which machine is best for shock absorber production testing?

STEP Lab’s EOL Series, designed for fast, reliable end-of-line validation.

Contact STEP Lab

Want to find out more about our Shock absorber testing machines? Contact us for any requests, detailed technical specifications, and customised configurations.