Everything you need to know about shock absorber test benches

Shock absorber test benches (or Shock dynos) play a crucial role in analysing the performance and durability of shock absorbers and dampers. These tests simulate real-life conditions and provide valuable information on the behaviour of a vehicle’s suspension system in various situations.

In the following, we will examine the main types of damper testing machines, describing their operation, characteristics and the advantages and disadvantages of each:

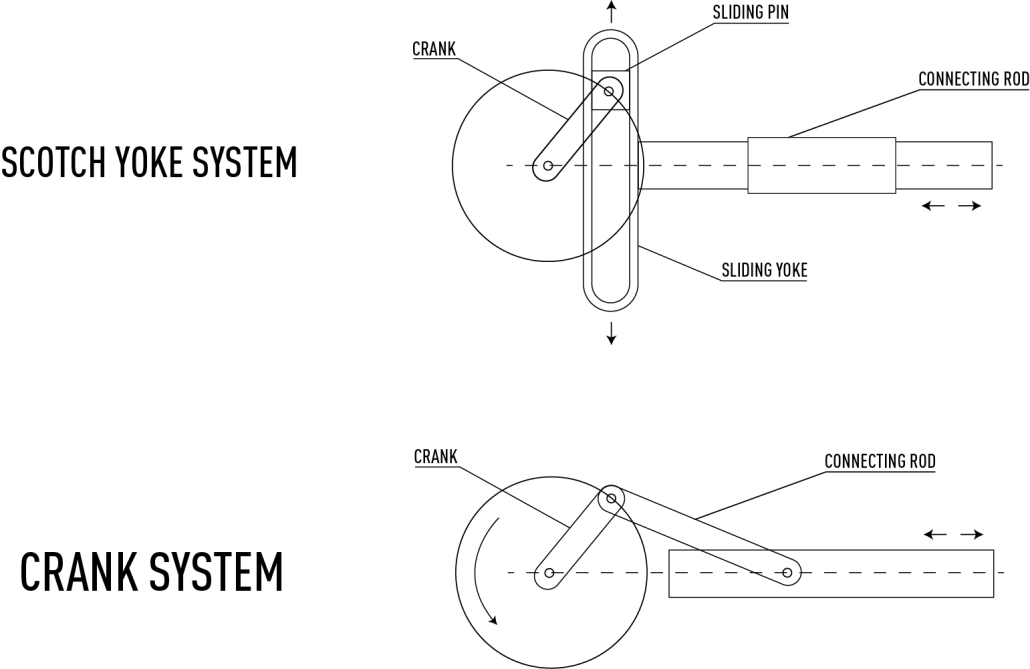

Scotch Yoke Shock Absorber Test Bench: Pros and Cons

Shock absorber test benches using the Scotch-Yoke mechanism to simulate forces are probably the most popular type of shock dynos for testing dampers and suspensions. These dynamometers have the following advantages:

- Simplicity: they have a simple mechanical design, with a single mechanism that converts rotary motion into linear motion.

- Compactness: they are suitable for testing applications with limited space.

- Convenience: they have low installation costs.

- Ease of use: they require relatively little operator training.

However, shock dynos with a Scotch Yoke mechanism also have certain limitations:

- Limitations in force replication: they cannot replicate a specific range of force profiles and road conditions.

- Lower load capacity: compared to hydraulic or electromechanical benches.

- Stroke is adjusted manually: the set-up of a test could take a lot of time.

- Typical load and speed range are limited to low values: the typical maximum values are 20 kN maximum load an 2.5m/s maximum speed.

Crankshaft Shock Absorber Test Bench: Pros and Cons

The crank system is very similar to the Scotch Yoke system, both in terms of advantages and disadvantages, and in terms of design and operating characteristics. The main difference lies in accuracy. Crank-operated dynamometers are less balanced and therefore less accurate, as the shock absorbers are mounted directly on the crank. This results in lateral movements that compromise the accuracy of the test. A possible solution could be the use of software filters, although the results are less accurate and reliable.

Electromechanical Shock Absorber Test Bench: Pros and Cons

Electromechanical shock absorber test benches are ideal for replicating real-world road profiles, with increased load capacity and the ability to adjust stroke and speed. These type of shock dyno offers the following advantages:

- Accuracy: they allow precise control of the force applied, ensuring accurate replication of road conditions.

- Possibility of complex tests: they can simulate complex road profiles with customisable variables.

- Energy efficiency: they consume energy only when needed, reducing long-term operating costs.

- Low maintenance costs: they require less maintenance than hydraulic benches.

At STEP Lab, we have developed an electromechanical system for testing shock absorbers. This specific shock dyno is called LUD and here you can see how it works and its unique features.

Hydraulic Shock Absorber Test Bench: Pros and Cons

Hydraulic shock absorber test benches use hydraulic fluid to simulate the forces experienced by a vehicle’s suspension system. They can accurately replicate road conditions and generate precise force profiles, but they also have certain limitations:

- Safety risk: the use of high-pressure hydraulics carries risks of rupture and potential explosion, necessitating strict safety regulations.

- High maintenance costs: they require regular maintenance to ensure accurate performance and safety.

- High installation and usage costs: can be expensive to install and use, especially for smaller test facilities.

- Environmental concerns: potential leaks or spills of hydraulic fluid raise environmental concerns, requiring proper containment and disposal practices.

Electrodynamic Shock Absorber Test Bench: Pros and Cons

Electrodynamic shock absorber test benches are designed to outperform hydraulic systems, effectively meeting the demand for:

- High performance

- Ease of installation

- Low power consumption

Electrodynamic shock absorber test benches can perform high-dynamic characterisation tests and shock absorber durability tests.

At STEP Lab, we have divided our electrodynamic systems into two main families: HUD and XUD.

- HUD line is designed for high-dynamic characterisation tests, with peak dynamic loads up to 66 kN and continuous dynamic loads up to 24 kN, and tests to assess the durability of the shock absorber under analysis. For higher loads, check the KUD Series (up to 160 kN).

- XUD line, on the other hand, is designed for very high-dynamic characterisation tests, with test acceleration up to 100 G.

Thank you for reading this overview of the different types of shock absorber test benches and their features. For more information on our range of test benches, please visit our dedicated page HERE.