ISO standards are essential to ensure uniform, reliable and internationally comparable material tests.

They define methods and parameters for testing mechanical, physical and chemical properties, ensuring quality and safety.

In the field of plastics,ISO 178 is the main standard for flexural testing, which is essential for assessing the strength and stiffness of materials.

What is ISO 178?

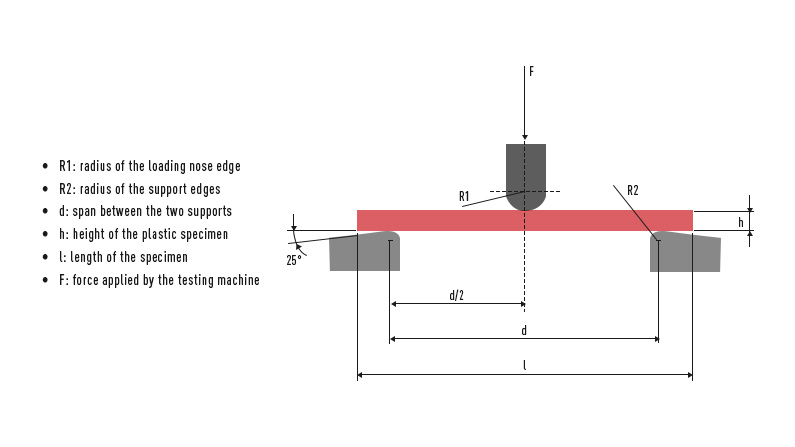

ISO 178 is an international standard that defines the test method for determining the bending properties of rigid and semi-rigid plastics. The test consists of applying a concentrated force to the centre of a specimen resting on two supports, so that the specimen is stressed at three points of contact: the two supports and the point of application of the load.

This test mainly measures two key parameters: the flexural modulus, which indicates the stiffness of the material under bending stress, and the flexural strength, which is the maximum load the material can withstand before breaking or permanently deforming.

The standard is essential for evaluating the mechanical behaviour of plastics in applications where bending stresses are critical, such as structural components, enclosures and machine parts.

In addition, ISO 178 provides precise guidelines on test tube sizes, test speeds, environmental conditions and calculations to be performed to ensure repeatability and comparability of results.

What does ISO 178 measure?

ISO 178 measures the mechanical flexural properties of plastics, providing essential data for understanding how a material responds to flexural stress.

In particular, the main parameters measured are:

- Flexural modulus (or bending modulus): it indicates the stiffness of the material during elastic deformation under bending load.

It is the ratio of bending stress to unit strain, and represents the material’s ability to resist bending without undergoing permanent deformation. - Flexural strength: the maximum value of stress that the material can withstand before reaching fracture or permanent plastic deformation.

This value is crucial for the design of components subject to bending loads. - Flexural deformation: it measures the amount of deformation or displacement undergone by the specimen under load, useful for assessing the ductility or brittleness of the material.

The objective is to cause the specimen to deform until failure or, if this does not occur, until a flexural deformation of 5% is reached.

ISO 178 also specifies two test methods: Method A, which involves a constant strain rate throughout the test, and Method B, which starts with a rate and increases it once the initial elastic region of the material has been exceeded.

ISO 178 – Technical requirements

ISO 178 specifies well-defined accuracy requirements, both with regard to motion control and test equipment configuration.

The accuracy of the movement of the crossbar must be such that it allows a resolution of at least 1 per cent of the flexural deformation used for the calculation of the modulus of elasticity.

The standard test speeds are:

- 1 mm/min for specimen thicknesses between 1 mm and 3.5 mm

- The standard allows a tolerance of ±20% on these speeds

For force measurement, load cells must provide high sensitivity and resolution, in line with the accuracy required for calculating the modulus of elasticity and other parameters.

ISO 178 – Required equipment

Tests according to ISO 178 are generally performed on bench test systems, as the forces required are relatively low.

The test machine must be able to maintain a constant speed of between 1 and 500 mm/min, within the tolerances specified in the standard.

The force measuring device (load cell) must comply with class 1 of ISO 7500-1 for the force range used.

It is therefore essential that the laboratory knows precisely the minimum and maximum forces to be applied, in order to select a suitable load cell, both in terms of capacity and verification range.

The equipment for the three-point bending test must meet the following conditions:

- The two side supports must be parallel with a tolerance of ±0.2 mm on the specimen width

- The distance between the supports (indicated as ‘d’) must be adjustable, depending on the sample size

- The bending radius of the components in contact with the sample must be:

- R1 (flexor): 5.0 mm ± 0.1 mm

- R2 (side supports):

- 2.0 mm ± 0.2 mm for samples with thickness< 3 mm

- 5.0 mm ± 0.2 mm for sample thickness ≥ 3 mm

These parameters guarantee the uniformity of the test and the repeatability of the results obtained on rigid and semi-rigid thermoplastic materials.

ISO 178 – Test specimens

Test specimens for the flexural test in accordance with ISO 178 can be: machined from sheets in accordance with ISO 2818, compression-moulded in accordance with ISO 293 or ISO 295, or injection-moulded in accordance with ISO 294-1 or ISO 10724-1.

The preferred sample sizes are:

- Length: 80 mm ± 2 mm

- Width: 10 mm ± 0.2 mm

- Thickness: 4 mm ± 0.2 mm

If these dimensions cannot be met, the standard allows the use of alternative widths proportionate to the thickness of the specimen.

ISO 178 – Test method

The distance between the bottom supports (opening of the three-point device) is configured according to the thickness of the specimen, as indicated by the standard.

The environmental conditions of the test – e.g. high or low temperature – must be determined according to the type of material tested and agreed upon between the laboratory and the client.

In the absence of specific guidelines, reference is made to ISO 291 for standard conditions.

ISO 178 defines two ways of performing the test:

- Method A: it uses a constant crossbar speed for the entire duration of the test.

- Method B: involves two speeds, an initial one for determining the modulus of elasticity, followed by a higher speed for completing the test.

After a preload phase, the specimen is either stressed to failure or until a flexural strain of 5 per cent is reached, whichever occurs first.

During the entire test, load and deflection data must be recorded with a sufficient acquisition frequency to ensure the accuracy of the results.

It is strongly recommended to set an adequate preload: the initial force applied to the test specimen before starting the test has a direct impact on the repeatability and reliability of the deformation calculations.

Testing machine for ISO 178

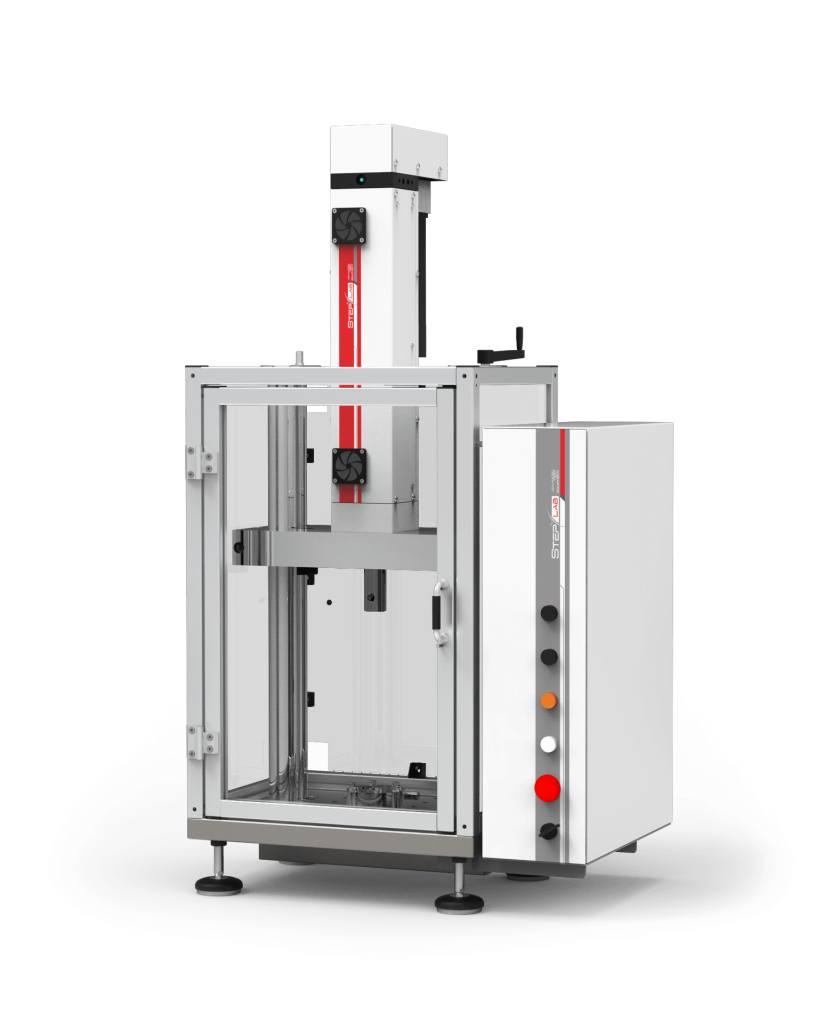

For ISO 178 compliant testing, STEP Lab offers the EA Series, designed to offer high accuracy, measurement reliability, and a wide range of force capabilities.

These test machines guarantee accurate test speed control and full compliance with regulatory requirements.

To find out all the details on the EA Series, click on the button below.