WHAT IS ISO 22675?

ISO 22675 is an International Standard that defines the test methods for ankle-foot devices and foot units. It provides two test procedures, one cyclic, designed for ankle-foot devices used in external lower limb prostheses, and one static. The loading conditions are characterized by standardized formats of loading and locomotion profiles, and each sample of device is free to develop its individual performance under load. By subjecting these devices to rigorous testing, ISO 22675 establishes performance requirements for strength, durability, and service life.

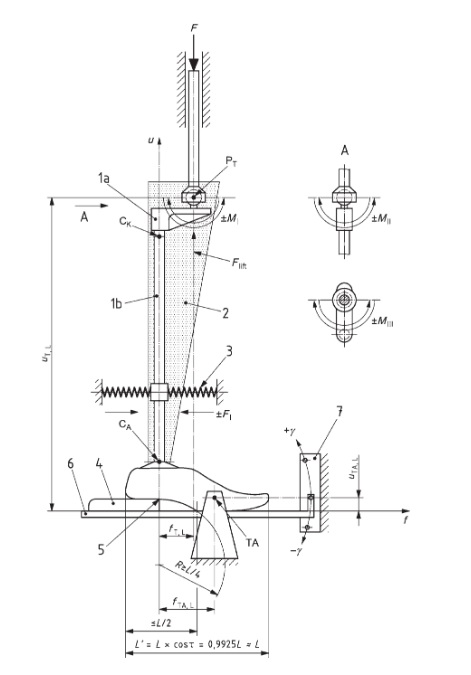

ISO 22675 – Test Setup

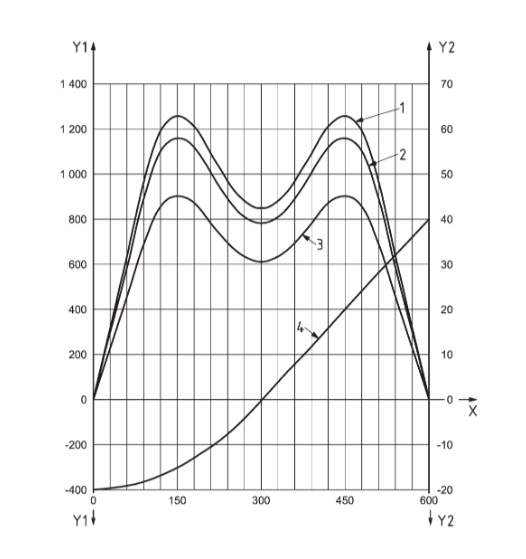

ISO 22675 – Test Graphs

ISO 22675 – CYCLIC TEST

The cyclic test outlined in ISO 22675 plays a crucial role in evaluating the functionality of ankle-foot devices. It assesses their ability to withstand the forces and stresses encountered during normal walking. By subjecting the devices to simulated real-life loading conditions, the test helps ensure that they meet the necessary performance standards.

This test, utilizing a pulsating test force and tilting angle, simulates the loading conditions of the complete stance phase of walking and verifies the strength, durability, and service life of the devices. Each loading condition generates compound loadings that simulate walking and other single events of loading. The test applies to ankle-foot devices and foot units of any size by establishing a relationship between the position of the top load application point and foot length.

- For the cyclic fatigue test, the specified number of cycles is 2×10^6.

In the 2024 version, cyclic testing is now linked to newly introduced Test Ranges (R2, R3, R4), each with defined walking characteristics, number of cycles, and angular conditions (like toe-out and tilt). This structure allows tailoring the test to the intended use and user mobility level.

Each range defines unique cyclic loading parameters based on intended mobility level and user activity. It includes:

- Number of load cycles

- Tilting and toe-out angles

- Application positioning based on foot length

This modular structure allows more realistic and targeted fatigue testing.

ISO 22675 – STATIC TEST

In addition to the cyclic test, ISO 22675 also covers three static tests to evaluate the structural strength of ankle-foot devices:

- Static proof test

- Static ultimate strength test

- Static torsion test (introduced in 2024)

The 2024 edition adds a detailed method to assess shock absorption capacity, measuring the energy absorbed during deformation. This includes applying load until failure or significant deflection, calculating both actual and theoretical energy, and verifying compliance against defined thresholds.

It also introduces a separate static torsion test to evaluate resistance to twisting loads. The method combines vertical and torsional loading and measures angular deformation, offering a new perspective on real-world performance.

ISO 22675: VERSIONS COMPARED

| Aspect | 2016 Version | 2024 Version |

|---|---|---|

| Test Ranges (R) | Not defined | Introduced R2, R3, R4 with detailed locomotion profiles and cycle numbers |

| P6–P8 Loading Levels | Optional and not validated | Integrated into the core standard |

| Shock Absorption Evaluation | Not specified | Defined in detail with procedures and energy calculations |

| Static Torsion Test | Not included | Mandatory for torsional strength assessment |

TESTING MACHINES FOR ISO 22675

At STEP Lab, we offer a full range of testing machines designed to comply with the new requirements of ISO 22675.

- Our EA dynamic and fatigue testing machine covers cyclic and static loading with high accuracy and reliability, supporting force control up to 200 kN.

- To the new static torque test, we respond with the BV torsional actuator, which can be easily integrated in the system creating a multi-axial testing machine, providing full support for all ISO 22675:2024 requirements.

- All systems feature zero-maintenance actuation, energy-efficient performance, and intuitive software tailored for biomedical standards.

Fully compliant multiaxial systems for ISO 22675:2024 will be available starting in 2026.