Ceramic materials play a pivotal role in modern dentistry, being utilized in a diverse array of applications. To ensure the quality and reliability of these materials, adherence to stringent standards is paramount. ISO 6872, titled “Dentistry – Ceramic Materials,” serves as a cornerstone in this regard by specifying the requirements for ceramic materials used in dentistry.

At STEP Lab, we take adherence to ISO 6872 seriously, employing cutting-edge testing equipment and methodologies to ensure the quality and reliability of our ceramic materials.

WHAT IS ISO 6872?

ISO 6872 is an internationally recognized standard that focuses on ceramic materials utilized in dentistry. It offers detailed guidelines and specifications aimed at guaranteeing the quality, safety, and performance of these materials across various dental applications, such as fillings, crowns, veneers, and implants.

Additionally, ISO 6872 establishes fundamental methods for flexural strength testing, which is vital for evaluating ceramic materials intended for dental use. This standard outlines procedures for conducting flexural strength tests using either three or four-point bending setups. This flexibility in testing methodologies enables thorough assessments of material properties, ensuring compliance with stringent quality standards.

WHAT DOES ISO 6872 MEASURE?

One of the key parameters addressed by ISO 6872 is fracture toughness, which is a critical property for dental ceramics. Fracture toughness measures a material’s ability to resist fracture when subjected to stress, making it an essential factor in determining the durability and reliability of dental prostheses. By assessing fracture toughness, dental professionals can predict how well a ceramic material will perform in clinical situations, leading to better treatment outcomes and patient satisfaction.

WHY IS ISO 6872 IMPORTANT?

The importance of ISO 6872 lies in its ability to standardize the testing and evaluation of dental ceramics, ensuring consistency and reliability across different products and manufacturers. By adhering to the requirements of this standard, dental laboratories and manufacturers can produce ceramics that meet stringent quality standards, minimizing the risk of material failure and enhancing patient safety. Additionally, ISO 6872 helps dental professionals make informed decisions about the selection and use of ceramic materials, ultimately improving the overall quality of dental care.

ISO 6872 – HOW TO PERFORM A TEST

ISO 6872 provides detailed procedures for conducting fracture toughness tests on dental ceramics. These procedures include specimen preparation, notch formation, and mechanical testing. Specimens are carefully fabricated according to specific dimensions and notch configurations to ensure consistency and accuracy in the test results. Mechanical testing is typically performed using either three-point or four-point bending setups, with precise loading conditions and measurement techniques employed to assess fracture toughness accurately.

Three flexural test methods are acceptable:

- three-point bending

- four-point bending

- biaxial flexure (piston-on-three-ball)

ISO 6872 – EQUIPMENT AND SETUP

To perform fracture toughness tests according to ISO 6872, specialized equipment and fixtures are required. This includes a diamond saw for cutting specimens, a single-edged razor blade for notch formation, and a three-point or four-point test fixture for mechanical testing. Additionally, precise measurement tools such as micrometers and calibrated microscopes are used to determine specimen dimensions and notch depths accurately.

Overall, ISO 6872 plays a crucial role in ensuring the quality and reliability of ceramic materials used in dentistry. By following the guidelines outlined in this standard, dental professionals can make informed decisions about the selection and use of dental ceramics, leading to improved patient outcomes and satisfaction.

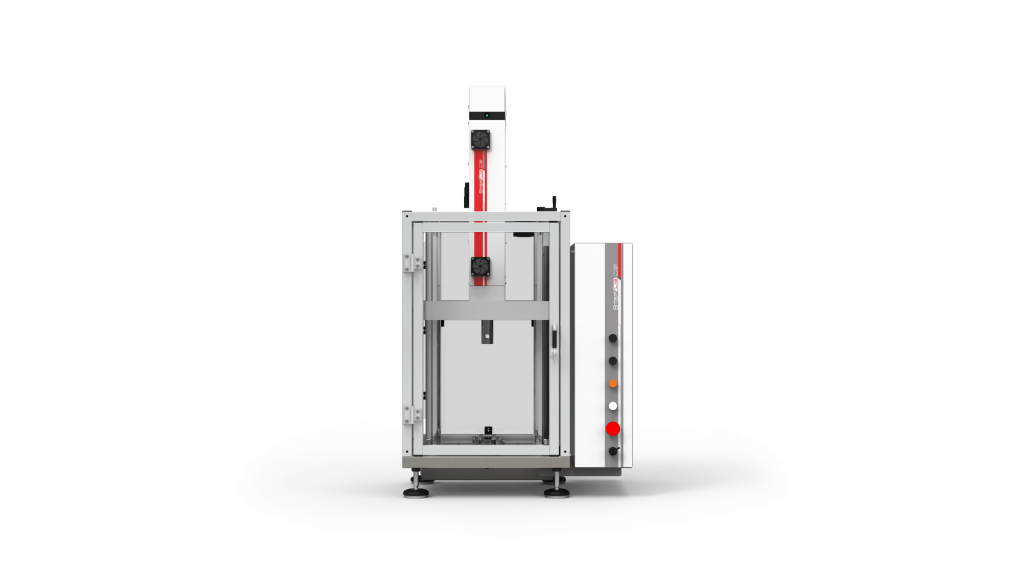

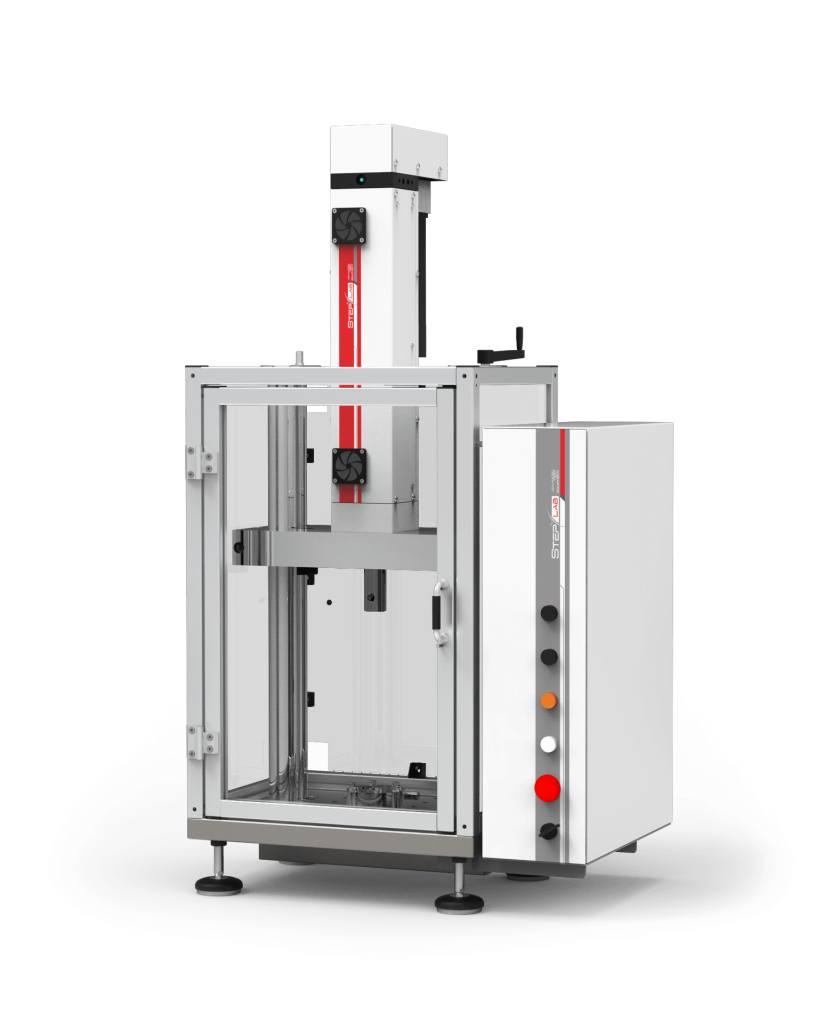

TESTING MACHINE FOR ISO 6872

At STEP Lab, our EA Series comprises the machines for executing tests in accordance with ISO 6872. Covering a load range from 200 N to 268 kN, these systems ensure precise control over compression parameters, guaranteeing reproducible and accurate results. Our electromechanical test systems are available in various models, offering variable loads, speeds, high-quality load frames, and intelligent drive systems to meet diverse testing needs.

Conduct tests in adherence to ISO 6872 standards with our EA Series, featuring:

- No maintenance

- Easy installation

- Low energy consumption

- Certified results

For more information on our impact test systems, click the button below.