WHAT ARE ISO 7206-4 AND ISO 7206-6?

The ISO 7206 series consists of international standards that specify requirements for mechanical testing of joint prostheses, with a particular focus on hip prostheses. ISO 7206-4 and ISO 7206-6 describe tests to evaluate the fatigue strength and durability of femoral components with stems in hip prostheses.

- ISO 7206-4 outlines a protocol for evaluating the endurance characteristics of femoral components in hip joint prostheses, both as part of total hip joint replacements and when used alone in partial hip joint procedures. It establishes testing conditions to accurately reflect real-world performance factors and details the specimen preparation for testing.

- ISO 7206-6 specifies a method for assessing the endurance properties of femoral components in hip joint prostheses, both in total hip joint replacements and in partial hip joint procedures. It covers the principle, materials, apparatus, procedure, reporting, and disposal of test specimens.

WHY ARE ISO 7206-4 AND 7206-6 IMPORTANT?

The primary objective of ISO 7206-4 is to ensure that hip prostheses meet high safety and reliability standards. The tests described in the standard are designed to simulate the load conditions that the prosthesis stem undergoes during daily activities such as walking, running, and climbing stairs. The standard aims to:

- Verify the prosthesis’s resistance to static and dynamic loads.

- Ensure the prosthesis can withstand mechanical stresses over the long term.

- Minimize the risk of fracture or deformation of the prosthesis during its useful life.

- Provide a standardized framework for comparing prosthesis performance across different manufacturers.

The importance of ISO 7206-4 lies in its ability to ensure that hip prostheses undergo rigorous testing and meet high-quality standards.

ISO 7206 – GENERAL TESTING REQUIREMENTS

Tests according to ISO 7206-4 and ISO 7206-6 can be conducted using electrodynamic testing machines, such as the UD series. These systems not only meet the standard requirements but also allow for higher loads and cycle numbers.

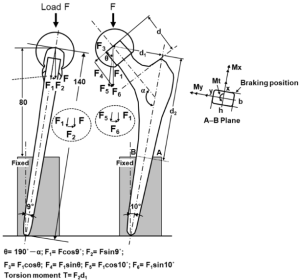

The general mechanical requirements defined by the standard, such as the orientation of the hip prosthesis concerning the test load, the mounting height, and the load application angle, can be precisely defined using specially designed test devices. These tools ensure pure axial loading on the femoral stem thanks to the use of compensating bearings.

Additionally, tests can be conducted under physiological environmental conditions, such as in a saline solution at a controlled temperature of 37°C, using specially designed fluid containers. This procedure is particularly important if the hip implant has conical connections in the stem or neck area.

ISO 7206-4 AND 7206-6: TESTING METHODS

- ISO 7206-4: Compressive, tensile, and bending forces are exerted on the femoral head to assess its endurance properties. The testing parameters ensure comprehensive evaluation and yield reliable predictions for in vivo performance. Specific values for test forces and the corresponding number of load cycles are defined.

- ISO 7206-6: Fatigue testing focuses on the neck of the implants and femoral components used in partial hip joints under controlled laboratory conditions. It sets out testing conditions to consider crucial parameters affecting component performance and outlines specimen preparation. Additionally, it references ISO 7206-4:2010 for specific test parameters and endurance limit requirements. Test forces and load cycle numbers are specified accordingly.

TESTING MACHINE FOR ISO 7206

At STEP Lab, our UD Series comprises the machines for executing tests in accordance with ISO 7206. With a maximum dynamic load of 100 kN, these systems ensure high performance with precise control over testing parameters, guaranteeing reproducible and accurate results. Our electrodynamic test systems are available in various models, offering variable loads, speeds, high-quality load frames, and intelligent drive systems to meet diverse testing needs.

Witness our electrodynamic machine in action, designed in compliance with ISO 7206 and featuring a unique setup with a torsional actuator and a liquid bath. The UD Series includes:

- No maintenance

- Easy installation

- Low energy consumption

For more information on our electrodynamic test systems, click the button below.