NEW SOFTWARE FOR DAMPER CHARACTERIZATION

Our new software platform has been redesigned from the ground up to deliver a modern, intuitive, and modular experience.

Whether you’re running basic characterization or advanced multi‑session tests, the software adapts to your workflow.

Key highlights:

- Simple and intuitive interface

- Multi‑language and multi‑unit support

- Modular architecture to activate only what you need

- Wizard mode to guide the user step‑by‑step through test setup

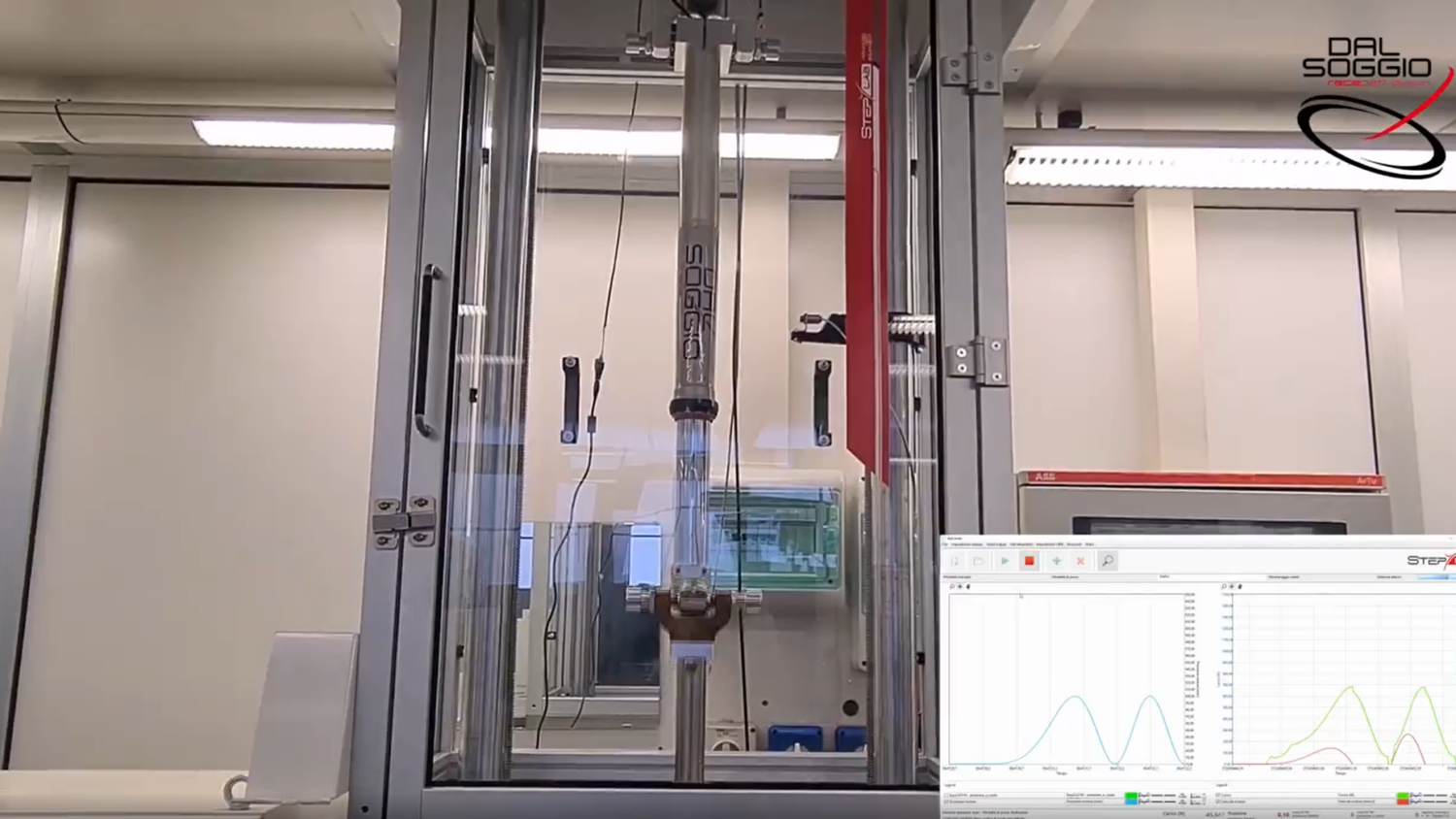

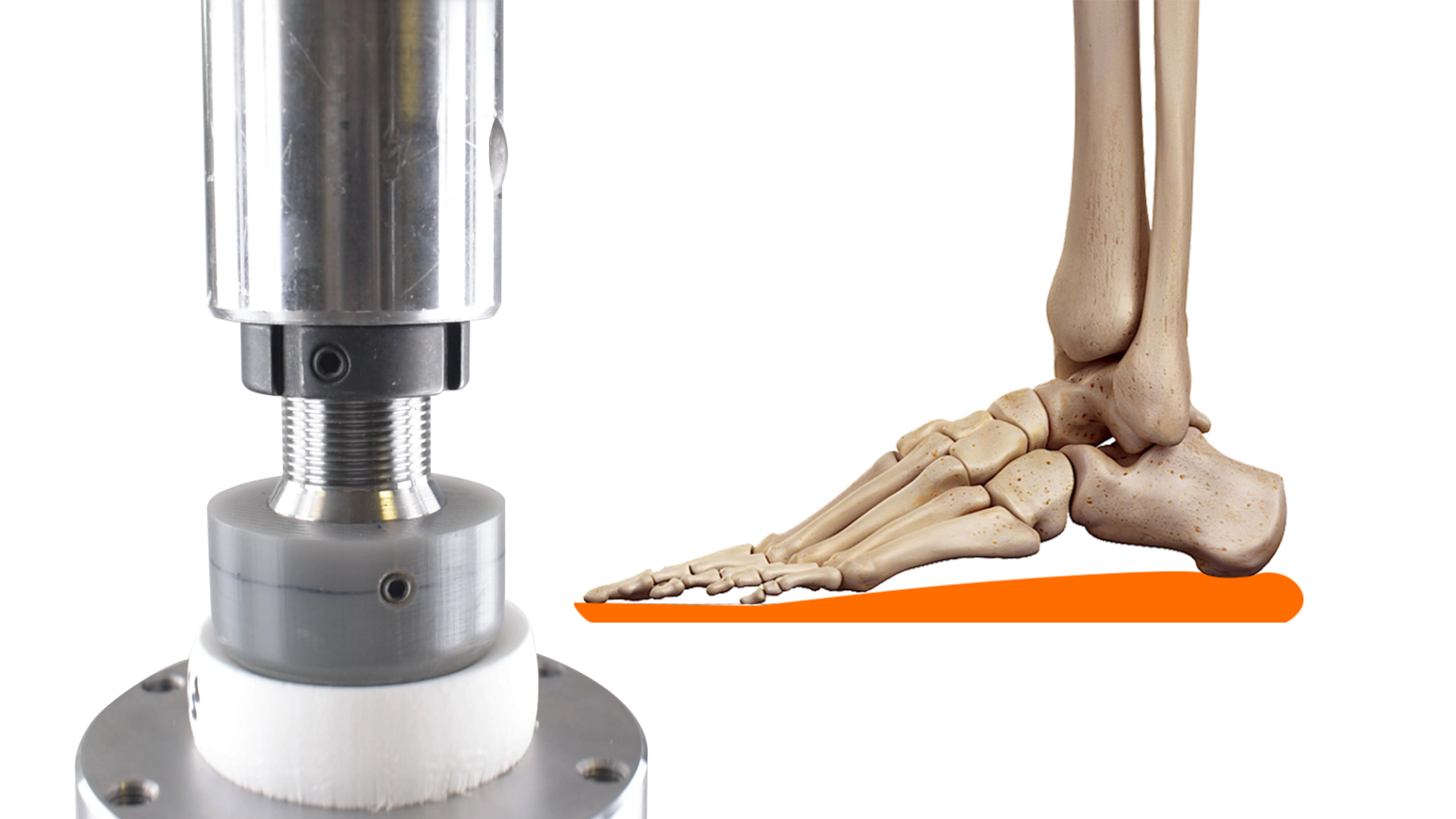

NEW 5-AXIS MACHINE FOR DENTAL IMPLANTS

This high quality table-top test frame is designed for dynamic tests of dental implants according to ISO 14801:2016.

Powered by five electromechanical EA02 actuators, it ensures quiet, clean operation and industry-leading performance thanks to its high efficiency and reliability.

Click the button below for more technical information.

EA025 – NEW ELECTRIC ACTUATOR!

Designed to replace hydraulic systems, it delivers high performance, low maintenance costs, and is built to last through billions of cycles. With up to 25 kN of dynamic load, 500 mm/s test speed, and 40 Hz frequency, EA025 is ideal for:

- Material testing

- Fatigue testing

- Static testing

To meet all your testing needs, a wide range of accessories (extensometers, climatic chambers, torsion actuators, and grips) is available.

THE NEW STEP LAB BRANCH IS NOW OPEN!

We’re excited to announce the opening of our new facility at 11148 Treynorth Dr., Suite C, Cornelius, North Carolina. This major milestone strengthens our ability to serve American partners with advanced testing solutions. Equipped with state-of-the-art technology and a skilled team, the new branch marks the start of a transformative journey in the U.S. Join us as we drive innovation and new collaborations across industries!

STEP LAB AND VI-GRADE ANNOUNCE STRATEGIC PARTNERSHIP FOR HIL SOLUTIONS

STEP Lab and VI-grade are teaming up to deliver a complete Mechanical Hardware-in-the-Loop (mHiL) solution for automotive shock absorber testing. Combining STEP Lab’s testing expertise with VI-grade’s AutoHawk platform and real-time software, the partnership streamlines development for active and semi-active suspension systems.

Check out the demo video from the 2024 ZERO PROTOTYPES Summit to see our Damper-in-the-Loop system in action!

UD100 – DYNAMIC TESTING AT 100 kN!

UD100 represents the future of electrical testing and the first machine capable of replacing hydraulic systems, with a dynamic force of 100 kN. UD100 is versatile and efficient, it handles fatigue tests, static tests, high-speed tensile tests and biaxial tests. Integrating seamlessly with the Test Center’s software ecosystem, UD100 offers a complete solution for materials analysis.

- 100 kN dynamic force

- Versatility in testing

- Integration with Test Center software

- 60% energy efficiency

- Zero maintenance costs

LUD – THE NEW SHOCK DYNO

LUD is our new Damper Electromechanical Testing Machine, the ultimate balance between high-level testing systems, like HUD and XUD, and entry-level options such as Crank and Scotch yoke Dynos. LUD is a smart investment that saves you money and improves your testing capabilities.

Watch LUD in action and click below to find out LUD unique features!

CHAMPION OF GROWTH!

Thank you to the German Institute of Quality for noticing and rewarding us! STEP Lab grew by more than 40% from 2018 to 2021.

We went from a turnover of 1,061 million to 2,918 in the same year and from 7 to 15 employees. Last year, we have grown exponentially compared to previous years!

HUD030 | DYNAMIC CHARACTERIZATION OF ANTI-SEISMIC AND ANTI-VIBRATION SUPPORTS

From construction sites to nuclear power plants, dampers play a crucial role in absorbing vibrations and protecting structures. We test them thoroughly with our HUD030 linear axis:

- Max frequency: 100 Hz

- Max test load: 20 kN

- Max test speed: 6 m/s

4-POSTER | FULL-VEHICLE TESTING

We’ve developed a portable demo for trade fairs featuring four high-dynamic electric linear actuators:

- Max peak force: 1.8 kN

- Max speed: 2.0 m/s

- Max frequency: 250 Hz

The full car test system uses actuators with:

- Max peak force: 80 kN

- Max speed: 8.0 m/s

- Max frequency: 250 Hz

Up to 8 actuators can be added for aerodynamic load and steering simulation, with flexible control options. Standard waveforms and field data playback supported!

HUD020L FOR DAMPER TESTING

TESTING MACHINE FOR SHOCK ABSORBER BELLOWS

Meet our special biaxial testing system for the automotive industry, designed for shock absorber bellows, axle shaft covers, and gearboxes.

Equipped with UD02 and UD04 linear axes and a two-stage climatic cell reaching -50°C, it also features a water and pollutant atomizer to simulate real-world stresses — ensuring durability without losing mechanical integrity!

AUTOMOTIVE STANDARDS

We’re certifying springs for household equipment according to ASTM, BS, DIN, and JIS standards.

Test conditions:

- Frequency: 3.6 Hz

- Max load: 2000 N

- Speed: 1.0 m/s

These international standards cover everything from design and manufacture to testing and inspection in the metal spring industry.