SPECIMEN GRIPS

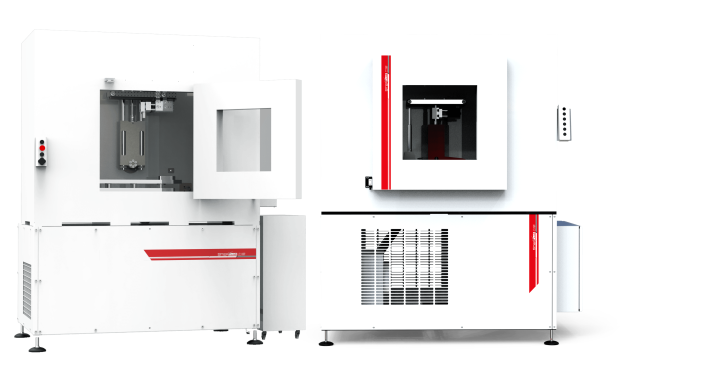

At STEP Lab, we offer a wide assortment of jaws, grips and clamps for testing materials and products. We have specially designed a wide selection of these instruments, including clamps and compression plates, to meet the specific requirements of each application, load and test material.

CHOOSING THE RIGHT GRIP

Type of test

Each test requires an appropriate gripping system to ensure the safety and reliability of the tests. Proper functioning of the clamp or test fixture is essential to obtain accurate results. For this reason, it is essential to select the most suitable clamp for each type of test. STEP Lab offers a wide range of grips and testing devices, covering a wide variety of applications, including tensile, compression, bending, shear and cyclic tests.

Specimen shape

Thanks to their flexible designs and mechanisms, gripping systems are compatible with different specimen shapes, sizes and materials, adapting to various loads and deformation ranges. Specific material characteristics, such as hardness, strength, ductility, elasticity and surface type, are crucial in selecting the most appropriate gripping system.

National standards

Standard specifications and general testing requirements are decisive in selecting the right clamp. For example, when testing high-performance specimens, the automatic application of clamping force, as required by pneumatic or hydraulic grippers, is necessary. When performing different types of tests, it is important that the gripping systems offer high flexibility, reducing replacement times and optimising operating costs.

FEATURES

High reliability

Wide range of use

Simple installation

OUR GRIPS

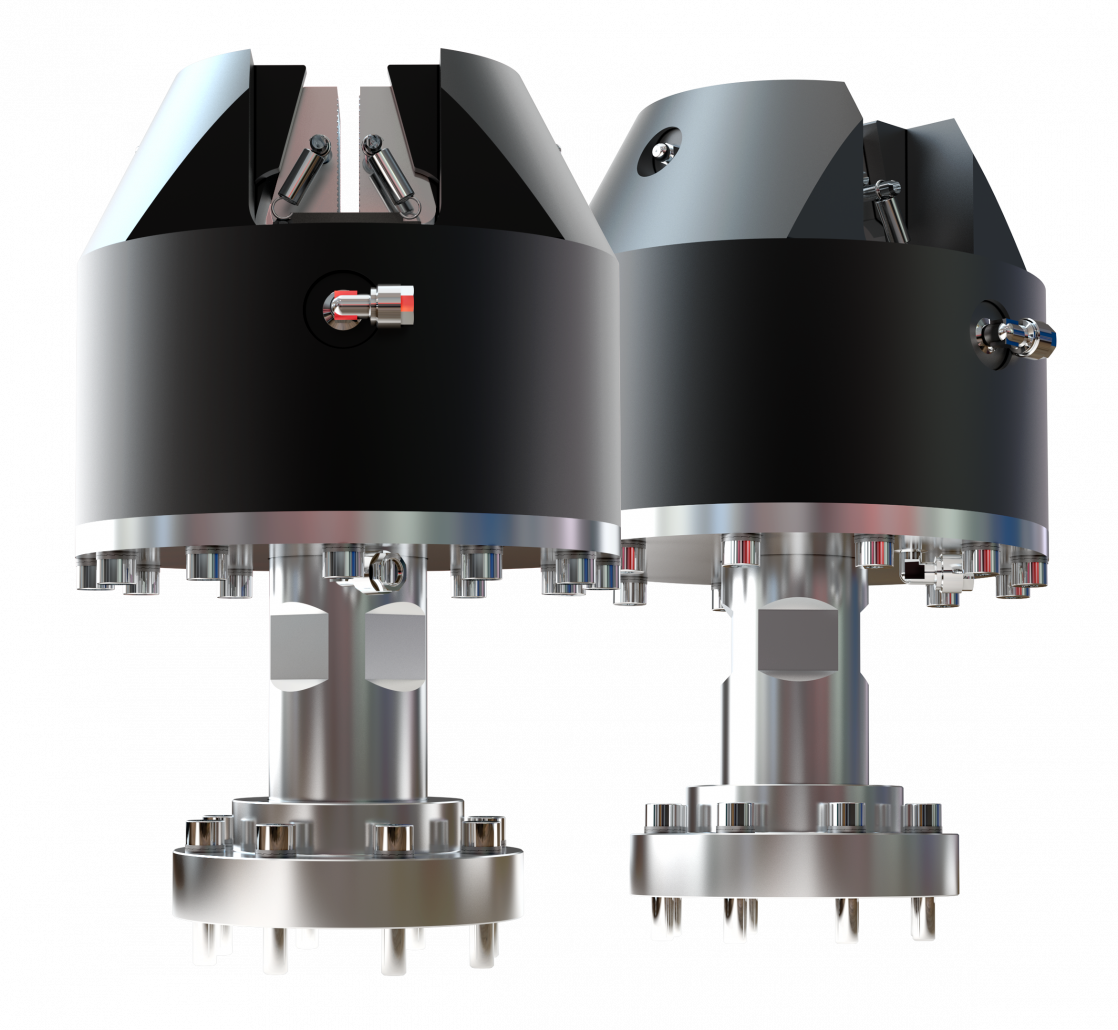

Hydraulic Grips

Hydraulic grips are mainly used with test loads from 50 kN in combination with high clamping forces.

- For uniaxial compression and tension tests – 50kN

- For biaxial compression, tension and torsion tests – 200Nm

Dimensions

- Flat

- 0-8 mm

- 8-12,7 mm

- Round

- 3 – 7,8 mm

- 7,1 – 12,7 mm

- 12,4 – 18 mm

Pneumatic Grips

Pneumatic clamps are particularly suitable for a wide variety of materials, especially those that are sensitive to clamping forces, with minimal changing effort. The clamping force is generated by pneumatic actuators acting directly on the grippers or via a lever system.

- For uniaxial compression and tension tests – 20kN

- For biaxial compression, tension and torsion tests – 200Nm

Dimensions

- Flat

- 0 – 8 mm

8 – 12,7 mm

- 0 – 8 mm

- Round

- 3 – 7,8 mm

- 7,1 – 12,7 mm

- 12,4 – 18 mm

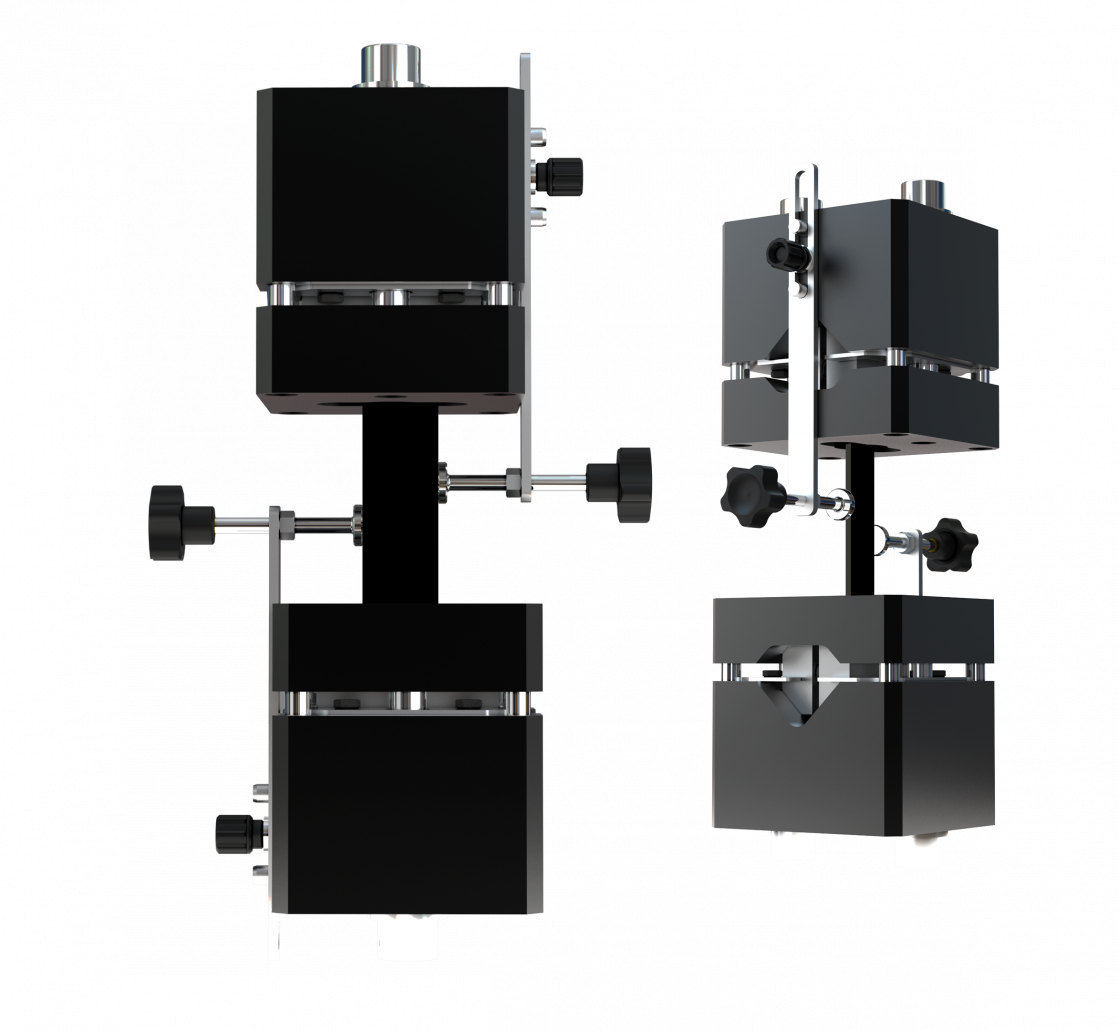

Manual jaws with 2/4 screws

Screw clamps are one-sided. The side screw is used to open and close the grips, and to apply the clamping force before the start of the test.

- For uniaxial compression and tension tests – 5/60kN

Dimensions

- Flat

- 0 – 8 mm

8 – 12,7 mm

- 0 – 8 mm

- Round

- 3 – 7,8 mm

- 7,1 – 12,7 mm

- 12,4 – 18 mm

Wedge Screw Grips

The wedge-screw grips are designed for easy loading, alignment and positioning of specimens. After initial contact with the specimen, the gripping force increases as the test load increases.

- For uniaxial compression and tension tests – 50kN

- For biaxial compression, tension and torsion tests – 140Nm

Dimensions

- Flat

- 0 – 8 mm

8 – 12,7 mm

- 0 – 8 mm

- Round

- 3 – 7,8 mm

- 7,1 – 12,7 mm

- 12,4 – 18 mm

Wedge grips

The manual wedge action grippers are designed to facilitate the loading, alignment and positioning of specimens. After initial contact with the test specimen, the gripping force increases as the test load increases.

- For uniaxial compression and tension tests – 15kN

Dimensions

- Flat

- 0 – 8 mm

8 – 12,7 mm

- 0 – 8 mm

- Round

- 3 – 7,8 mm

- 7,1 – 12,7 mm

- 12,4 – 18 mm