In the world of metallic materials, understanding their behaviour at high temperatures is crucial. At STEP Lab, we manufacture testing equipment in accordance with the most stringent international Standards, like ASTM E21. This standard is a fundamental element in the domain of single-axis elevated temperature tensile testing, commonly recognized as hot tensile testing.

WHAT IS ASTM E21?

ASTM E21 is a standard developed by ASTM International for conducting elevated temperature tensile tests on metallic materials. These tests are essential for evaluating a metal’s ability to withstand applied stress under elevated temperatures. The ASTM E21 standard covers procedures and equipment for determining key mechanical properties such as tensile strength, yield strength, elongation, and reduction of area. These tests are crucial in assessing the performance and behavior of metals at elevated temperatures, providing valuable insights into their structural integrity and suitability for specific applications.

WHAT DOES ASTM E21 MEASURE?

Tensile Strength

Tensile strength, a cornerstone parameter from ASTM E21 testing, signifies the maximum stress a material can withstand before necking, where the specimen’s cross-section contracts significantly during stretching or pulling.

Yield Point and Offset Yield

The yield point marks the stress at which a material begins to deform plastically. Offset yield, an extension of this concept, involves specifying a particular amount of plastic deformation before measuring yield stress.

Strain at Break and Reduction of Area

Strain at break reflects the extent of deformation a material undergoes before fracture, providing insights into its elongation capabilities. Reduction of area quantifies the reduction in cross-sectional area post-tensile testing, revealing the material’s ductility.

ASTM E21 – TESTING PROCESS

The ASTM E21 testing process involves measuring the minimum cross-sectional area, determining the original length and elongation, ensuring specimen cleanliness, maintaining temperature control, and connecting the specimen carefully to prevent nonaxial forces. Strain is measured and controlled during yield strength determination using an extensometer system. Maximum force is recorded, and post-test measurements assess elongation and reduction of area, comparing values against specified minimum requirements for acceptance tests.

ASTM E21 – TEMPERATURE REQUIREMENTS AND CLIMATIC CHAMBERS

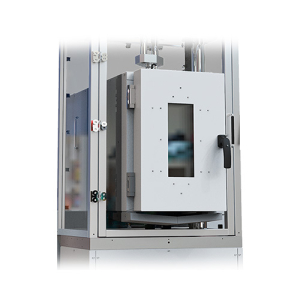

The elevated temperature hot tensile test, according to ASTM E21, is conducted in environments exceeding room temperature, specifically above 38 °C (or 100 °F). This procedure is facilitated within STEP Lab’s climatic chambers, specifically designed for precise environmental simulation testing. These chambers offer a temperature range up to +180°C and boast an impressive accuracy of ±1°C, streamlining the testing process for efficiency. Renowned for exceptional precision and flexibility, these climatic chambers ensure reliable results in conjunction with STEP Lab’s mechanical testing equipment.

Temperature measurement during the test is accomplished using thermocouples with the necessary sensitivity and reliability.

TESTING MACHINES FOR ASTM E21

ASTM E21 stipulates stringent requirements for testing machines in the elevated temperature tensile test on metals. Optimal and precise alignment of the testing machine is crucial when applying the load on the gripped specimen. The testing machine, along with specimen grips, must load a precisely machined specimen to ensure that the maximum bending strain does not surpass 10% of the axial strain.

Our dynamic and fatigue testing machines is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test