ELECTROMECHANICAL SYSTEMS IN 2025:

A MAJOR BOOST IN PERFORMANCE

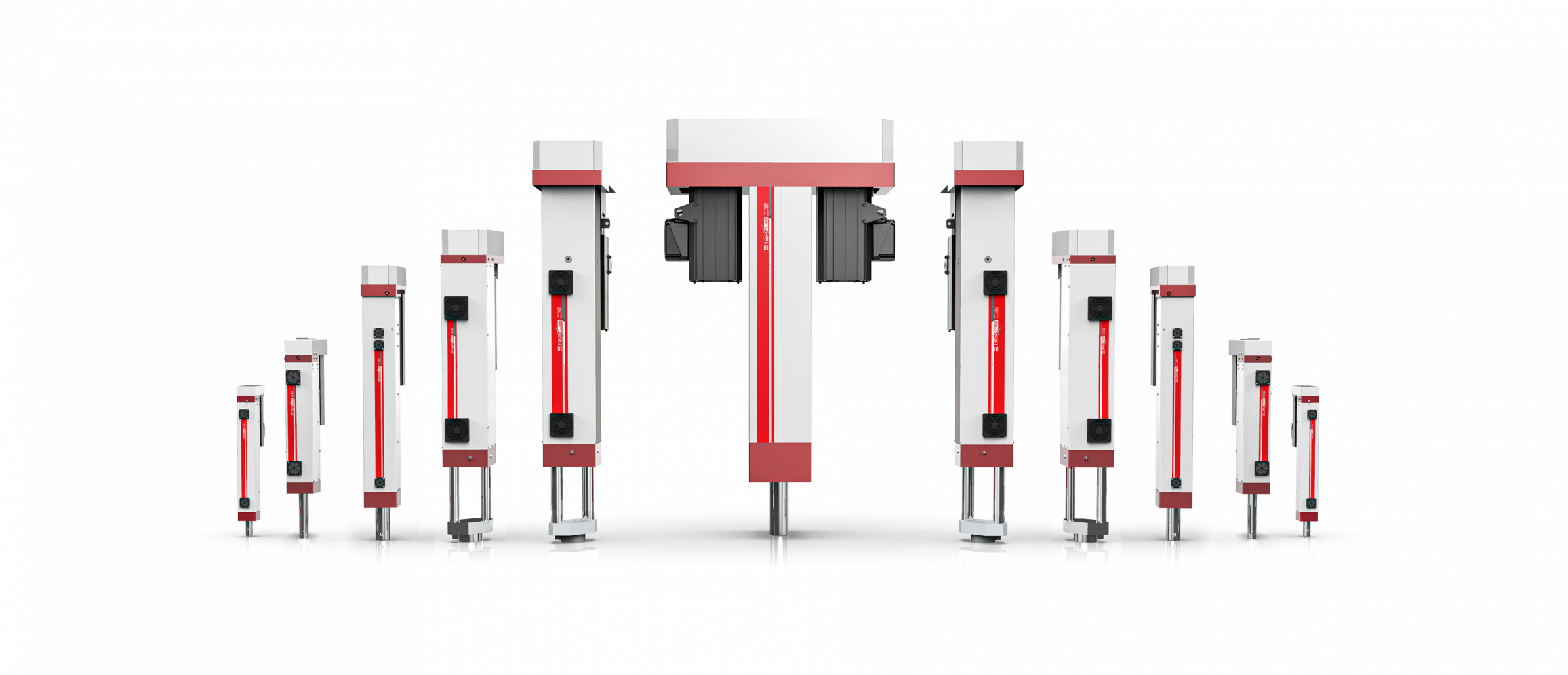

At STEP Lab, we’re driven by a passion for innovation and excellence. As leaders in electromechanical solutions, we’re not just keeping pace with the industry’s evolution—we’re setting the standard. In 2025, our commitment to performance, efficiency, and sustainability is propelling electromechanical systems to unprecedented levels. This article dives into how STEP Lab will significantly upgrade and improve the EA Series.

A Leap in Power and Size Optimization

The most interesting improvement of the electromechanical systems of EA Series is the size/force ratio. In the past, increased power often came with compromises in size, leading to bulkier systems that consumed more space and resources. However, 2025 marks a departure from this trade-off. For instance, STEP Lab’s latest actuators deliver significantly more force without an increase in physical size.

Take the EA05 actuator as an example. While maintaining the same compact dimensions, the new model will offer over three times the dynamic load capacity, jumping from 7.5 kN to an impressive 25 kN. This breakthrough enables manufacturers and engineers to integrate powerful systems into space-constrained environments without sacrificing performance.

Frequency and Weight

Another upgrade is the enhancement of operational frequency and weight efficiency. Many electromechanical systems now operate at higher frequencies, enabling faster and more precise testing cycles. The latest actuators, for instance, achieve a maximum frequency of up to 40 Hz, making them ideal for dynamic applications and fatigue testing.

Despite these performance enhancements, the systems remain lightweight. Weighing just 40 kg, they offer exceptional portability and ease of installation. This combination of power, speed, and lightness opens up new possibilities for applications in many industries like automotive and aerospace.

Energy Efficiency

In 2025, producing systems with high sustainability has become a priority. Electromechanical systems are becoming more energy efficient, reducing energy consumption and minimising waste. By optimizing energy use, the new systems not only enhance operational efficiency but also support companies in meeting their sustainability goals. This balance ensures that businesses can achieve superior performance while adhering to environmental regulations.

Unmatched Reliability

STEP Lab has also achieved significant progress in terms of durability and long-term performance. Electromechanical systems are now capable of performing billions of cycles, even under challenging conditions. This strenght is particularly crucial for applications that demand consistent performance over extended periods, such as fatigue and dynamic testing.

The actuators are built with premium materials and advanced engineering techniques, ensuring they withstand the test of time. This reliability not only minimizes downtime but also reduces maintenance costs, providing a significant advantage for industries that rely on continuous operation.