ISO 16955 provides a standardized method to evaluate the mechanical properties of prosthetic feet, offering objective and repeatable data about how a prosthetic foot performs during walking. The standard helps bridge the gap between mechanical lab testing and real-life user experiences by simulating the dynamic load and motion conditions of the human gait.

WHAT IS ISO 16955?

ISO 16955 is a technical specification developed to measure the dynamic mechanical performance of prosthetic feet during the stance phase of walking. It serves as an extension and refinement of ISO 22675, adding more detailed instrumentation and stricter controls to better simulate human walking and evaluate key characteristics like energy return, stiffness, and damping.

WHAT DOES ISO 16955 MEASURE?

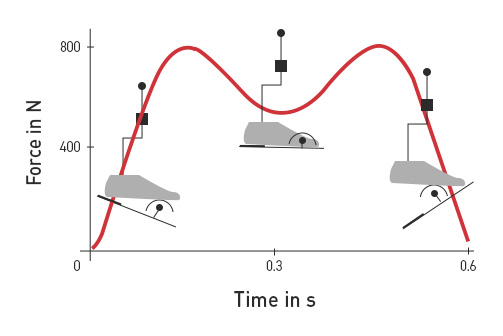

ISO 16955 quantifies the dynamic properties of prosthetic feet during the stance phase, from heel strike to toe-off.

Key measurements include:

- Multidimensional forces and torques applied during walking

- Energy return and absorption

- Stiffness profiles across the foot

- Load transfer and ground reaction forces

These values are crucial in evaluating how the prosthetic behaves under real-life conditions and in helping to match a device to the user’s mobility needs.

WHY ISO 16955 IS IMPORTANT?

Until now, prosthetic foot selection has largely relied on empirical testing with users or manufacturer-provided data. These methods are often subjective, non-replicable, and expensive. ISO 16955 introduces a reliable, standardized lab test that offers:

- Objective comparison between different foot models

- Faster, more cost-effective assessment methods

- Increased transparency for prosthetists and reimbursement bodies

- Better alignment between user needs and device performance

ISO 16955 IN DETAIL

Unlike its predecessor ISO 22675, ISO 16955 integrates multidimensional sensors and demands the elimination of gliding elements in the test rig. This ensures precise force and torque measurements without interference.

The procedure replicates realistic gait patterns to simulate walking and measures the resulting performance of the prosthetic foot. The specification includes test conditions that mirror human use more accurately than static or simplified dynamic tests.

By focusing on mechanical characterization rather than clinical trials alone, ISO 16955 offers a new benchmark for the development and selection of advanced prosthetic feet.

ISO 16955 – TESTING PROCEDURES

The prosthetic foot is mounted to a test system that simulates gait cycles, applying controlled vertical loads and angular motions.

Key aspects of the testing procedure include:

- Cyclic loading across multiple gait phases

- Use of force-torque sensors for 3D measurement

- Elimination of components that could skew results, like gliding joints

- Dynamic analysis from heel contact to toe-off

Each test yields mechanical data that can be used to generate performance curves, enabling direct comparison across different products.

ISO 16955 VS ISO 22675: WHAT’S THE DIFFERENCE?

While both standards are used to evaluate prosthetic feet, they serve different purposes. ISO 22675 focuses on durability through fatigue testing, whereas ISO 16955 aims to characterize how a prosthetic foot performs dynamically during walking.

The table below highlights the key differences:

| Aspect | ISO 16955 | ISO 22675 |

|---|---|---|

| Primary Focus | Functional performance of prosthetic feet | Structural durability and fatigue life |

| Test Type | Dynamic characterization of mechanical properties | Cyclic loading for endurance testing |

| Measurement Parameters | Forces, torques, stiffness, energy return | Number of cycles to failure under predefined loads |

| Sensors | Multidimensional force/torque sensors integrated | Basic load application, limited sensor requirements |

| Test Conditions | Simulated gait cycle (heel strike to toe-off) | Repetitive loading with simplified motion patterns |

| Realism | High – mimics stance phase of walking | Moderate – focuses on loading without full gait simulation |

| Gliding Elements | Must be eliminated to avoid measurement interference | Permitted |

| Use Case | Performance evaluation and foot selection support | Safety, certification, and durability validation |

TESTING MACHINES FOR ISO 16955

At STEP Lab, we’ve developed advanced machines designed specifically for ISO 16955 testing, enabling accurate and reproducible analysis of prosthetic feet performance under dynamic conditions. These systems must be capable of:

- Reproducing realistic gait kinematics

- Operating at variable speeds and loads

- Integrating multi-axis load cells and high-resolution sensors

- Avoiding elements that affect test purity, such as friction or backlash

Our EA dynamic and fatigue testing machine covers cyclic and static loading with high accuracy and reliability, supporting force control up to 200 kN.