At STEP Lab, our core mission is to produce advanced testing machines tailored for a variety of industries, including biomedical applications. Our technology is engineered to deliver superior performance and reliability, aligning seamlessly with global standards, notably ISO 11491. We are committed to meeting your materials testing needs with precision and compliance at the forefront of our priorities.

WHAT IS ISO 11491?

ISO 11491, titled “Implants for surgery – Determination of impact resistance of ceramic femoral heads for hip joint prostheses,” stands as a global standard integral to the assurance of reliability and safety in surgical implants. This standard sets the guidelines specifically aimed at testing the capacity of ceramic femoral heads to endure impacts. Through the methodologies detailed in ISO 11491, the assessment of durability and performance of these components becomes possible, thus adding to the overall quality and longevity of hip joint prostheses. In the realm of the medical device industry, adherence to this standard is crucial, as it advocates for standardized testing procedures for ceramic femoral heads, fostering improved patient outcomes and increased efficacy of implants.

WHAT DOES ISO 11491 MEASURE?

In gauging the proficiency of ceramic femoral heads, ISO 11491 places its focus on impact resistance, a parameter of great significance given the dynamic nature of hip joint movements. The standardized methods provided by ISO 11491 establish a uniform approach to evaluating the endurance and robustness of these ceramic components. This standardization is essential for ensuring the reliability of ceramic femoral heads in practical, real-world scenarios.

ISO 11491 – HOW TO PERFORM A TEST

The test procedure consists of several steps for evaluating the impact resistance of a ceramic femoral head.

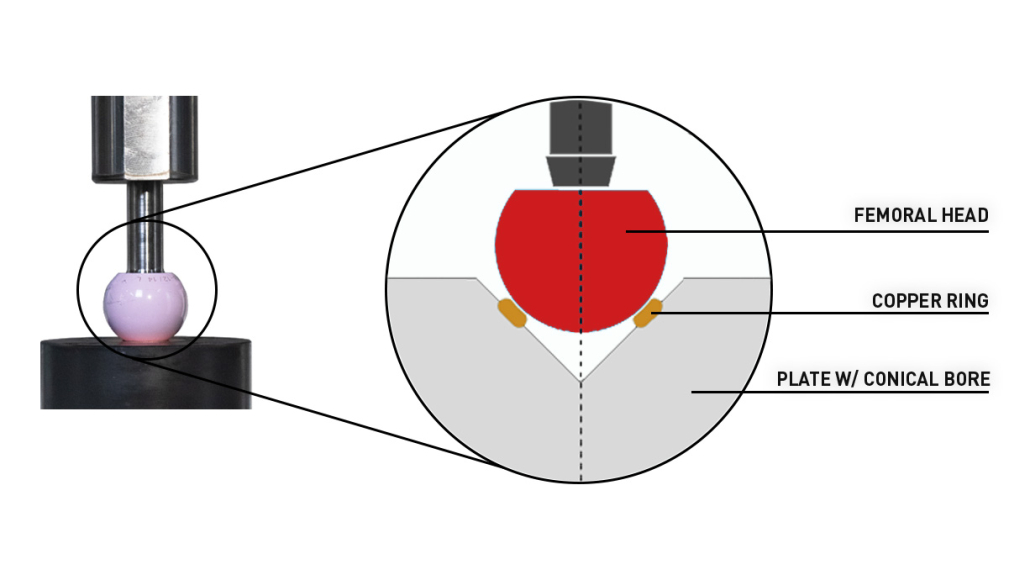

In the general procedure, the copper ring undergoes cleaning to remove oil, fat, and contaminants. A new ceramic femoral head, neck unit, and copper ring load distributing device are used for each test. Careful mounting of the femoral head onto the neck unit is emphasized to maintain alignment.

The test for impact resistance involves placing the specimen/neck unit assembly in the test machine, applying an initial impact energy of 20 J, and subsequently increasing the energy in 10 J steps. Regular examination of the conical loading bore is necessary, and damaged components, such as the copper ring, should be replaced after each test.

TESTING MACHINE FOR ISO 11491

The machine, firmly secured to the ground or a robust bench, deploys a falling or drop weight mechanism to deliver impacts to a test specimen. It accommodates an adjustable mass weight for variable heights, allowing a diverse range of impact energies. The falling weight, whether guided or free-falling, minimizes friction and avoids contact with the striking assembly.

The test specimen, comprising a head and neck unit, is supported on a holding block attached to a load cell. Precision is vital, demanding vertical alignment within ±1° and lateral alignment within ±1 mm for the falling weight’s axis, test specimen, holding block, and load cell.

Explore our Drop tower for impact testing solutions adhering to ISO 11491 standards. Visit our dedicated page for more information.

Conduct tests in adherence to ISO 11491 standards with our Drop Towers, featuring:

- Impact velocities up to 5.0 m/s (up to 20 m/s with a spring preload system)

- Range of standard drop weights (0.5 to 10 kg, totaling 70 kg)

- Impact velocity acquisition at 200 kHz

- Force signal acquisition rate up to 10 MHz.

For more information on our Drop weight towers, click the button below.